Separation and purification method of colistin sulfate

A technology of colistin sulfate and purification method, which is applied in the field of separation and purification of colistin sulfate, can solve the problems of large amount of sulfuric acid, complicated process, long cycle, etc., and achieves the advantages of improving yield, less degradation and avoiding titer reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The titer of the fermentation broth is 550,000 units, and the pH is adjusted to 4.0 with 40% sulfuric acid.

[0022] Ceramic membrane filtration: The ceramic membrane is selected as model 19-3.8, the pore size is 200nm, the operating conditions are inlet pressure 3.5bar, outlet pressure 2.0bar, the fermented liquid with pH 4.0 is concentrated twice, the filter residue is treated separately, and the titer of the dialyzed liquid is About 200,000, adjust the pH to 4.5-5, and another batch to 7.5.

Embodiment 2

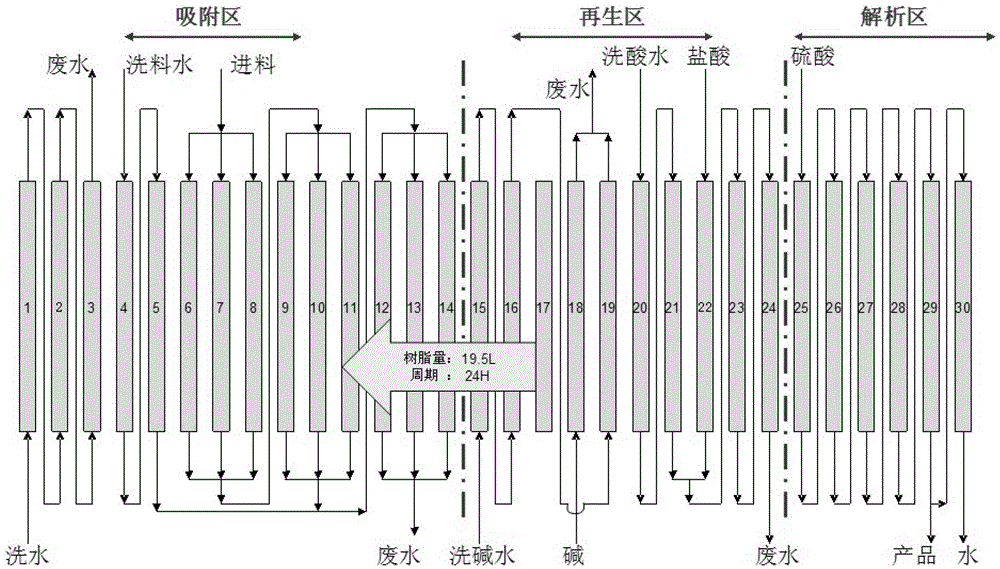

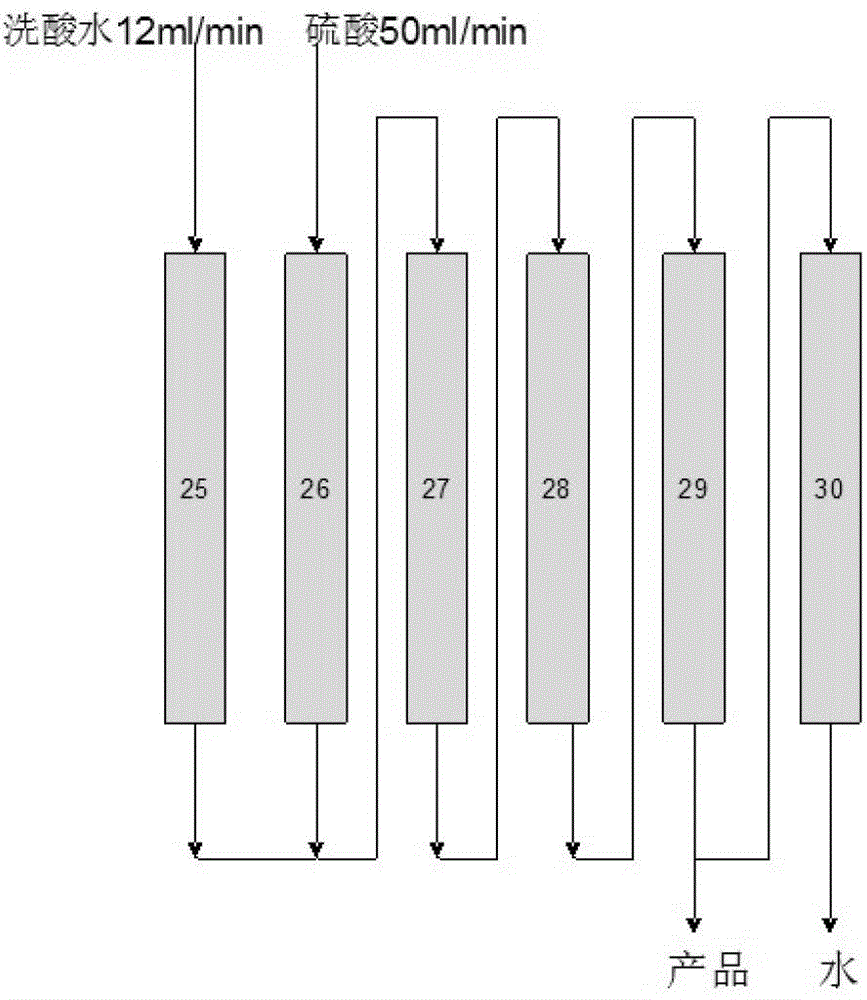

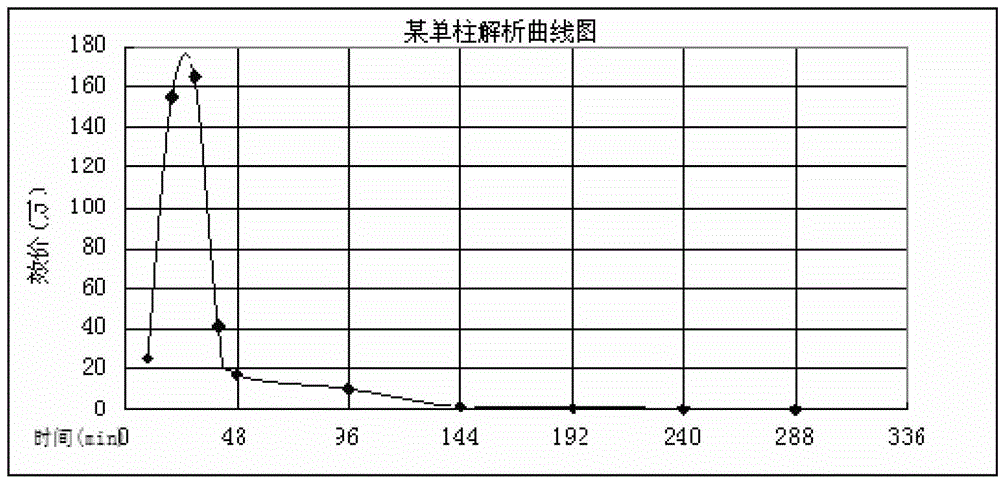

[0023] Embodiment 2 Continuous ion exchange parameters are determined

[0024] 1. Equipment: The equipment used is a 30-valve continuous ion exchange system provided by Sanda Membrane Technology Co., Ltd., with a single column volume of 900ml, a resin filling volume of 650ml for a single column, and a total volume of 19.5L.

[0025] 2. Feed liquid: The ceramic membrane filtrate in production, adjust pH value 4.5-5.0 and pH value 7.5 or so respectively

[0026] 3. Use of chemicals: H 2 SO 4 Solution (0.5mol / L)

[0027] NaOH solution (1mol / L)

[0028] 4. Water: industrial pure water

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com