Polybutylene composite board and production method

A production method and technology of polybutene, which is applied in the field of polybutene composite board and production, can solve the problems of easy breakage and falling off, and achieve the effects of good sealing, stable physical properties and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

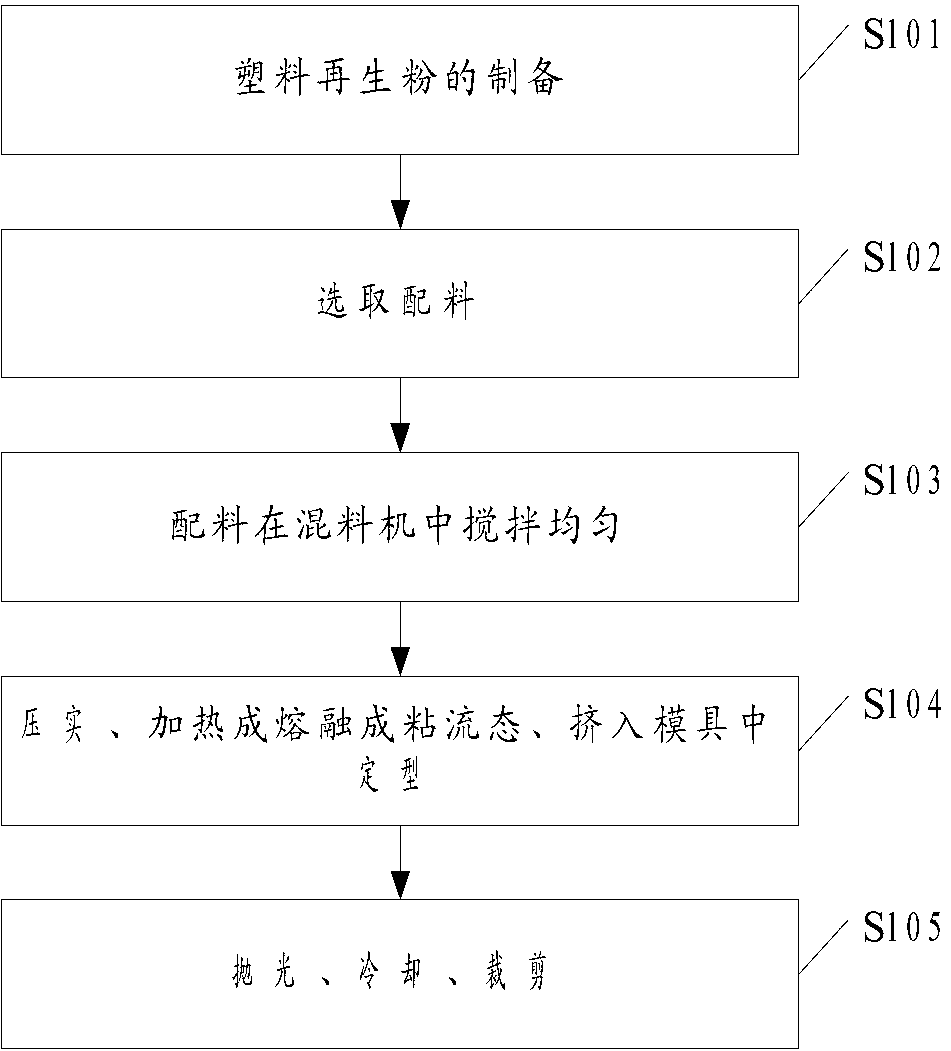

[0026] S101, preparation of recycled plastic powder;

[0027] First crush it with a crusher and then grind it into powder with a mill.

[0028] S102, selecting ingredients;

[0029] According to the weight ratio, 20%~35% of recycled plastic powder, 30%~50% of polybutene, 10%~25% of calcium powder, 1%~10% of antimony trioxide, 1%~5% of stabilizer and titanium dioxide 1%~10%; paraffin 0.1%~5%, static agent 1%~10%; called ingredients. Among them, paraffin wax and static agent can be added according to needs. The paraffin wax increases the plasticity of the polybutene composite board, and the electrostatic agent increases the antistatic function of the polybutene composite board.

[0030] S103, the ingredients are stirred evenly in the mixer;

[0031] The mixing unit of the mixer is composed of a hot rolling pot and a cold rolling pot. The prepared raw materials are heated and stirred by hot mixing, so that the additives can penetrate into the raw materials, and then put into ...

Embodiment 1

[0046] 20g of recycled plastic powder, 50g of polybutene, 10g of calcium powder, 10g of antimony trioxide, 1g of stabilizer and 10g of titanium dioxide are mixed to make a polybutene composite board according to the above steps.

Embodiment 2

[0048] 35g of recycled plastic powder, 30g of polybutene, 25g of calcium powder, 1g of antimony trioxide, 5g of stabilizer and 10g of titanium dioxide are mixed to make a polybutene composite board according to the above steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com