High temperature resistant secondary sintering curing type powdery coating

A secondary sintering and powder coating technology, applied in the coating field, can solve the problems of damage, no published patent documents, and no coating protection effect, and achieves increased production cost, good practicability and energy saving, and excellent adhesion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

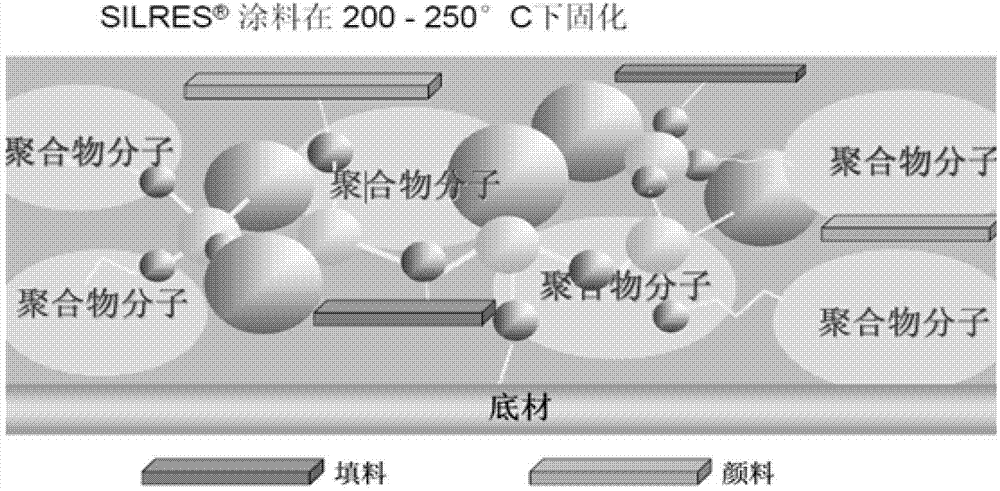

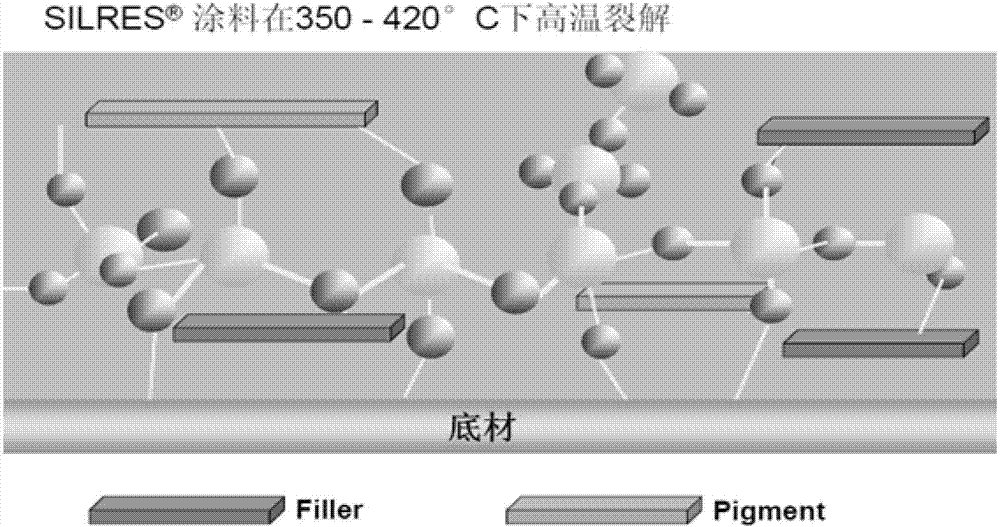

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0023] A high temperature resistant secondary winding solidification type powder coating, its raw material components and parts by weight are respectively:

[0024]

[0025]

[0026] The preparation method is:

[0027] 1. Mix mica powder, quasi-spherical silica powder, low-melting glass powder, silane coupling agent, polyether-modified siloxane, high-temperature pigment (silicon carbide powder), strontium aluminum phosphate, and ultra-fine aluminum powder in proportion by weight Weigh and add to the mixer for pretreatment, stir and mix at low speed for 30 minutes, seal and mature for 48 hours;

[0028] 2. Pour Silres605 (wacker, curing agent B1530) into the mixer according to the weight ratio, dry mix and stir at high speed for 8-10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com