Epsilon-polylysine fed batch fermentation method for enhancing cell growth and bioprocess efficiency

A technology of fed-batch fermentation and polylysine, which is applied in the field of ε-polylysine fed-batch fermentation, can solve the problems that affect the synthesis ability of ε-polylysine of cells, the difficulty of fundamentally increasing cell density, and the problem of cell density. It can improve the synthesis ability of ε-polylysine, overcome the pH control fermentation, and enhance the cell activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Preparation of spores

[0020] Fresh epsilon-polylysine producing bacteria Streptomyces ahygroscopicus str-8 (this bacteria was preserved in China Center for Type Culture Collection on June 2, 2011, preservation address: Wuhan University, Wuhan, China, preservation The number is: CCTCC NO: M2011191, the preservation information of this strain is disclosed in the patent number: ZL201110152802.0, the name of the invention is: Streptomyces nonhygroscopicus Str-8 and the method for preparing ε-polylysine and its salt In the patent) the slant strains were streaked and inoculated in oat agar medium (ISP3) for multiple times, cultured upside down at 30°C for 7 days, washed with sterile water to collect mature spores, and prepared spore suspension as inoculum, usually The concentration of spore suspension can be obtained under the condition of about 5×10 8 CFU / mL.

[0021] Preparation of oat agar medium (ISP3): Weigh 40g of oats, wash with deionized water, place in a 1L be...

Embodiment 2

[0031] 1, spore preparation and seed liquid cultivation are the same as in Example 1, thus obtaining the seed liquid.

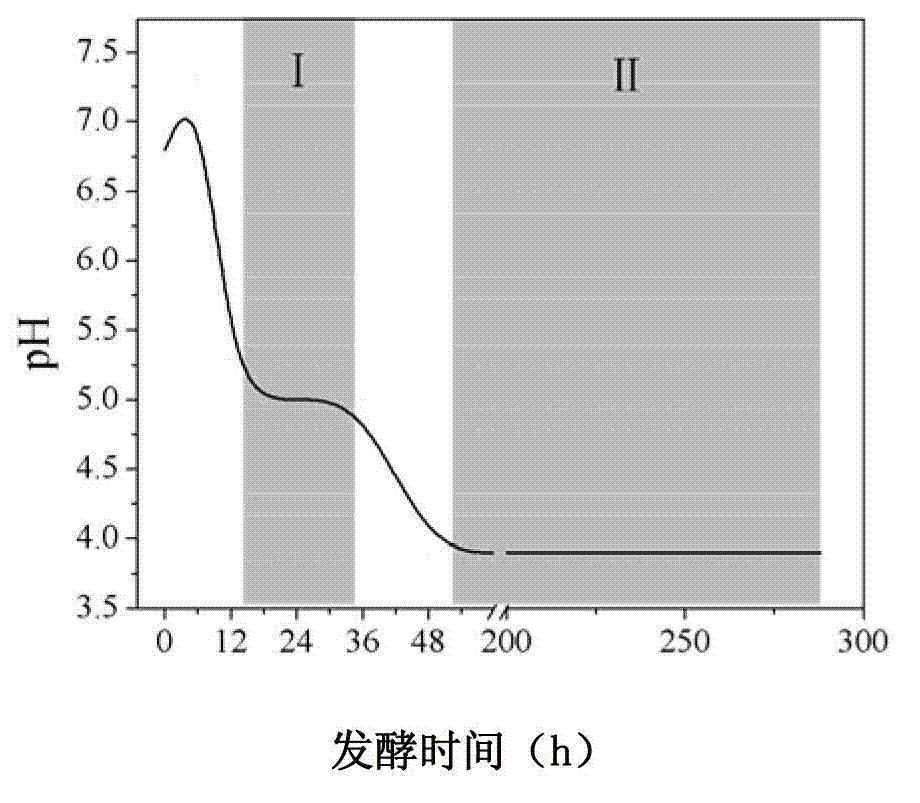

[0032] 2. Fed-batch fermentation process of fermenter

[0033] Take 150mL seed liquid and inoculate it in sterilized 2.85L M3G medium (5L fermenter), the temperature is 30°C, the rotation speed is 300r / min, and the ventilation is 1vvm. defoaming.

[0034]After the fermenter is inoculated with the seed liquid, when the pH of the fermentation medium in the culture system drops to about 3.6, apply 10% ammonia water on-line to control the pH of the culture system to maintain a level between 3.6 and 4.1 until the end of fermentation , that is, one-stage pH control; and when the pH drops to 3.6, the sterilized yeast powder solution (200g / L) is added continuously (adding 0.025g of yeast powder per liter of fermentation medium per hour) to Fermentation ends to enhance cell growth and activity.

[0035] During the fermentation process, cell growth and ε-polylysine ...

Embodiment 3

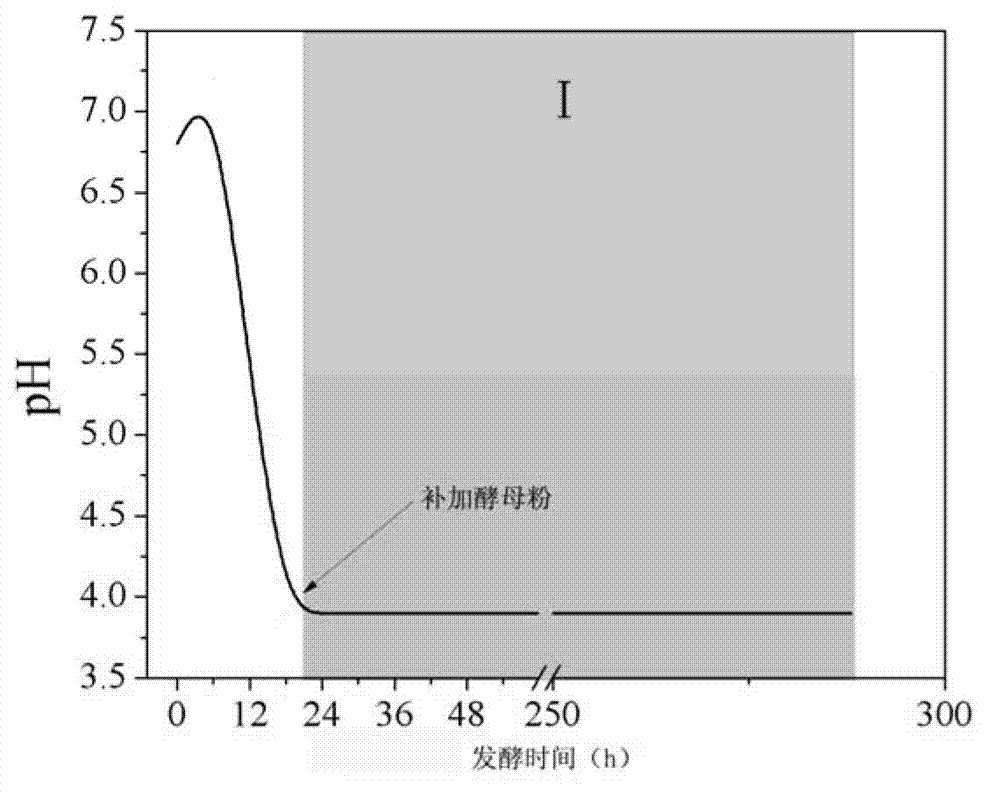

[0038] 1, spore preparation and seed liquid cultivation are the same as in Example 1, thus obtaining the seed liquid.

[0039] 2. Fed-batch fermentation process of fermenter

[0040] Take 150mL seed liquid and inoculate it in sterilized 2.85L M3G medium (5L fermenter), the temperature is 30°C, the rotation speed is 300r / min, and the ventilation is 1vvm. defoaming.

[0041] After the fermenter is inoculated with the seed liquid, when the pH of the fermentation medium in the culture system drops to about 4.1, apply 10% ammonia water to control the pH of the culture system on-line to maintain the pH of the culture system at 4.1 until the end of the fermentation, that is, the first stage pH control; and when the pH drops to 4.1, the yeast powder solution (200g / L) of continuous feed sterilization (adding the amount of 0.5g yeast powder in every liter of fermentation medium per hour) to the end of fermentation, to Improves cell growth and activity.

[0042] During the fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com