Refining method of aluminum-magnesium-series cast aluminum alloy material

A technology for casting aluminum alloy and aluminum magnesium, which is applied in the field of metal materials, can solve the problems of not being able to meet the needs of large-scale alloy production, and has not found any published patent documents, etc., and achieves guaranteed yield, reduced oxidative combustion, and low magnesium burning loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

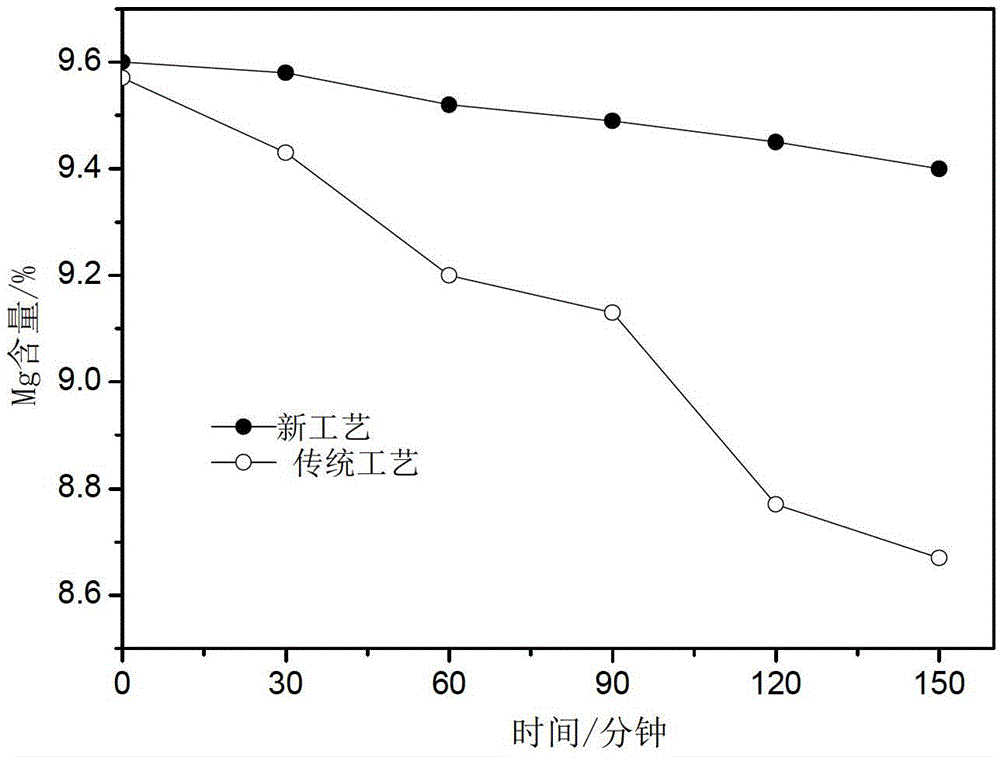

Embodiment 1

[0043] A method for refining aluminum-magnesium cast aluminum alloy materials. The LZ.AlMg9 alloy is prepared in this example. The steps are as follows:

[0044] (1) The total ingredients are 80Kg, according to the requirements of the alloy composition (Si: 1.0-1.5; Mg: 8.0-10.5; Al is the balance), weigh the required amount of metal magnesium 7.76Kg, metal silicon 1Kg, remelted aluminum ingot 71.24Kg, And preheat all materials.

[0045] (2) Weigh 0.12Kg of high-magnesium aluminum alloy HGF-1 refining agent, weigh 0.14Kg of XH-2 covering agent for aluminum-magnesium alloys, and dry all the weighed fluxes.

[0046] (3) Sequentially add the remelted aluminum ingots and metal silicon preheated in step (1) into the industrial electric furnace, and heat up together with the furnace body.

[0047] (4) After heating and melting, stir the melt evenly, adjust the melt temperature to 755°C, and press the weighed metal magnesium into the bottom of the molten aluminum until it is complet...

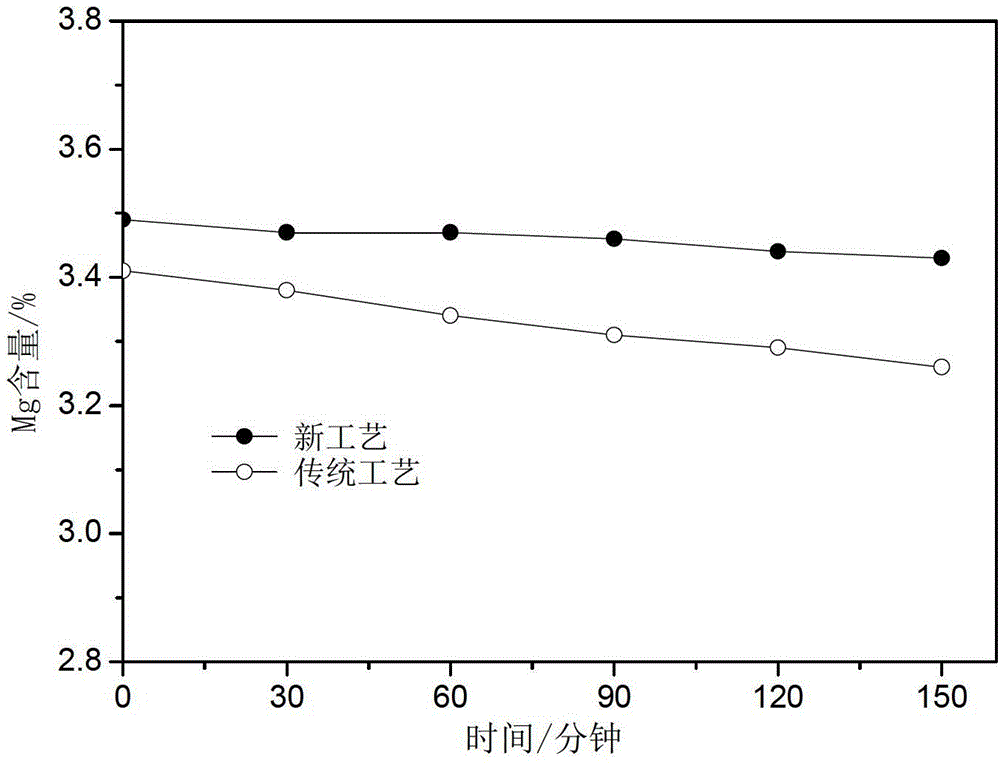

Embodiment 2

[0053] A method for refining aluminum-magnesium cast aluminum alloy materials. In this embodiment, LHM.GIBBS alloy is prepared. The steps are as follows:

[0054]⑴The total batching is 80Kg, according to the requirements of the alloy composition (Si: 0.2~0.3; Mg: 2.6~3.7; Fe: 0.2~0.5; Mn: 0.6~0.75; Ti: 0.03~0.07; Al is the balance) to weigh the required The amount of magnesium metal is 2.8Kg, silicon metal is 0.2Kg, aluminum-iron master alloy is 3.2Kg, aluminum-manganese master alloy is 5.6Kg, aluminum-titanium master alloy is 0.4Kg, and remelted aluminum ingot is 67.8Kg. And preheat all materials.

[0055] (2) Weigh 0.10Kg of high-magnesium aluminum alloy HGF-1 refining agent, weigh 0.12Kg of XH-2 covering agent for aluminum-magnesium alloys, and dry all the weighed fluxes.

[0056] (3) Sequentially add the remelted aluminum ingots and metal silicon preheated in step (1) into the industrial electric furnace, and heat up together with the furnace body.

[0057] (4) After hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com