Steam action-based metal material surface modification method and device therefor

A metal material and surface modification technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of product quality stability, process window narrowing, health and environmental safety hazards, etc. Achieve the effects of eliminating potential hazards to the ecological environment and human health, high treatment efficiency, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

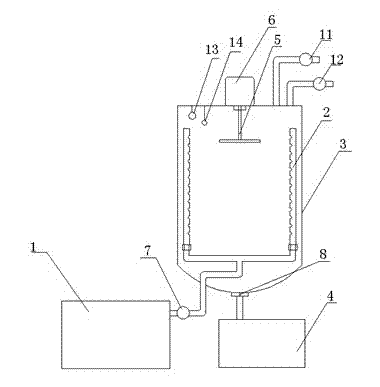

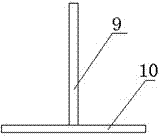

Embodiment 1

[0036] Taking as-cast high-purity magnesium and magnesium alloy AZ91 as the test objects, wire-cutting processed them into samples with a size of 25mm×25mm×5mm. After metallographic polishing, they were ultrasonically cleaned with absolute ethanol, and after drying, they were clamped with fixtures and fixed on the carrier. On the rod 10, the airtight reaction chamber 3 is closed. Using deionized water as feed water (raw material), start steam generator 1 to produce steam. Start the driving motor 6 to make the sample rotate at a constant speed, open the intake valve 7, and introduce the saturated steam generated by the steam generator 1 into the chamber of the reaction chamber 3 through the intake valve 7, and adjust the exhaust valve 11 and the intake valve 7 The opening degree is controlled to control the temperature of saturated steam at 150, 200 and 250°C (corresponding pressures are 0.48, 1.54 and 3.77MPa, respectively). After 1 hour, the inlet valve 7 was closed, and aft...

Embodiment 2

[0038] Except that the deionized water in the steam generator is changed into tap water, other is the same as embodiment 1. Results The surface of all samples was covered with a layer of complete, uniform, smooth and dense film.

Embodiment 3

[0040] Except that the deionized water in the steam generator is changed into distilled water, other are the same as embodiment 1. Results The surface of all samples was covered with a layer of complete, uniform, smooth and dense film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com