Low-temperature and low-damage multifunctional composite coating device and method

A composite coating and multi-functional technology, which is applied in the field of low-temperature and low-damage multi-functional composite coating devices, can solve the problems of damage temperature, low thermal conductivity of flexible materials, etc. Effects of radiation, avoiding direct bombardment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

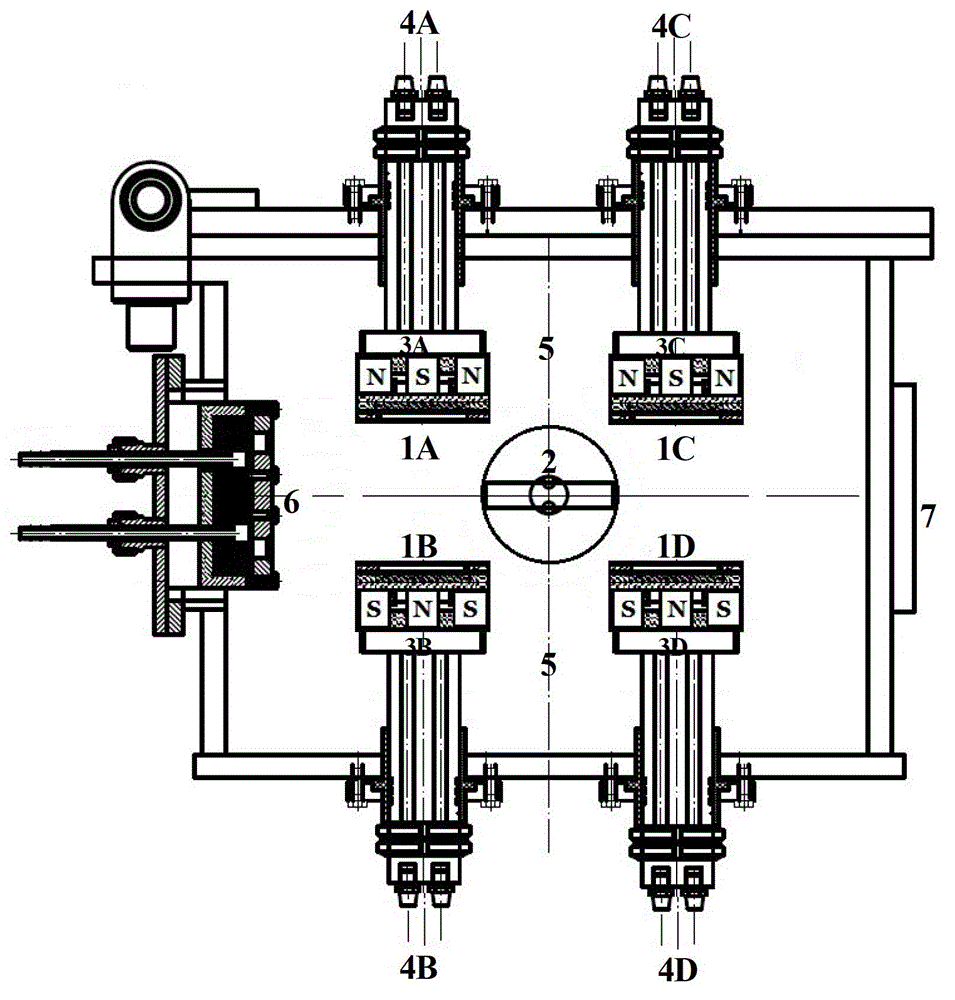

[0042] Such as figure 1 As shown, the whole vacuum system of the device of the present invention mainly includes: the first group of targets (the A side 1A of the first group of targets and the B side 1B of the first group of targets) arranged in the vacuum cavity 5, the workpiece turret 2, Magnet system (magnet system A part 3A, magnet system B part 3B), low temperature linear ion source 6, and the second set of targets (the second set of target C surface 1C and the second set of target D surface 1D), the magnet system (Magnet system C part 3C, magnet system D part 3D), etc. The specific structure is as follows:

[0043] The surface 1A of the first group of target materials and the surface 1B of the first group of target materials are set opposite to each other, with a distance of 12cm, and the angle between the target and the target is 0 degrees. The ion source 6 is located on the side of the first group of targets, and plays the role of ion cleaning and auxiliary depositi...

Embodiment 2

[0051] Such as figure 1 As shown, the whole vacuum system of the device of the present invention mainly includes: the first group of targets (the A side 1A of the first group of targets and the B side 1B of the first group of targets) arranged in the vacuum cavity 5, the workpiece turret 2, Magnet system (magnet system A part 3A, magnet system B part 3B), low temperature linear ion source 6, and the second set of targets (the second set of target C surface 1C and the second set of target D surface 1D), the magnet system (Magnet system C part 3C, magnet system D part 3D), etc. The specific structure is as follows:

[0052] The surface 1A of the first group of target materials and the surface 1B of the first group of target materials are set opposite to each other, with a distance of 12cm, and the angle between the target and the target is 0 degrees. The ion source 6 is located on the side of a group of targets, and plays the role of ion cleaning and auxiliary deposition. The ...

Embodiment 3

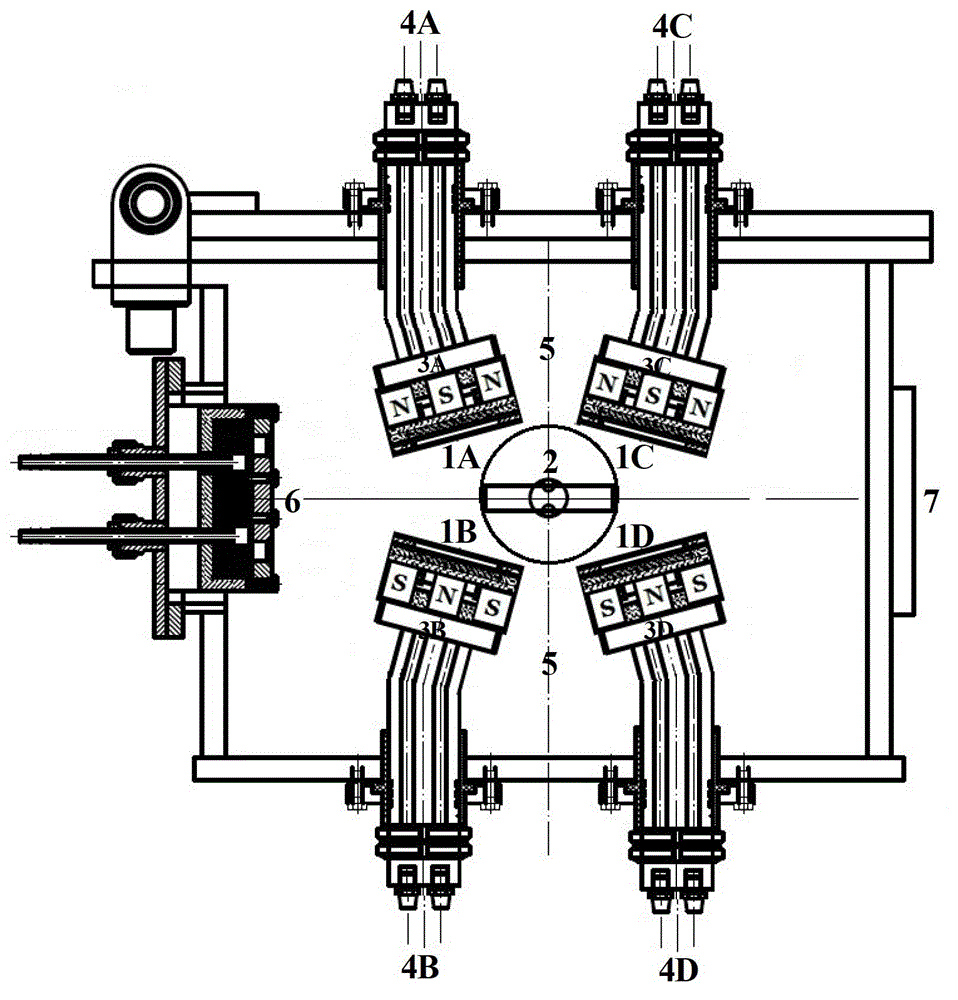

[0060] Such as figure 2As shown, the entire vacuum system of the device of the present invention mainly includes: the first group of targets (the first group of target A side 1A and the first group of target B side 1B) arranged in the vacuum chamber 5, the second group of target (The second group of targets C surface 1C and the second group of targets D surface 1D), workpiece turret 2, magnet system (magnet system A part 3A, magnet system B part 3B), magnet system (magnet system C part 3C, Magnet system D part 3D), low temperature linear ion source 6, etc. The specific structure is as follows:

[0061] The first group of targets A surface 1A and the first group of targets B surface 1B are set opposite to each other, with a distance of 12cm, and the angle between targets is 15 degrees, and the second group of targets C and surface 1C are opposite to the second group of targets D. Set, the distance is 12cm, and the angle between target and target is 15 degrees. The workpiece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com