Preparation method of collagen coating embedded with chitosan microspheres on medical metal implant surface

A technology of chitosan and implants, which is applied in the field of preparation of chitosan microsphere collagen coating embedded on the surface of medical metal implants, to achieve the effect of improving slow-release behavior, wide application prospects, high-efficiency loading and slow release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Chitosan is dissolved in the acetic acid solution of 166.7mM, prepares the chitosan acetic acid solution of 12.5g / L, adjusts the pH value of chitosan acetic acid solution to be 5.0;

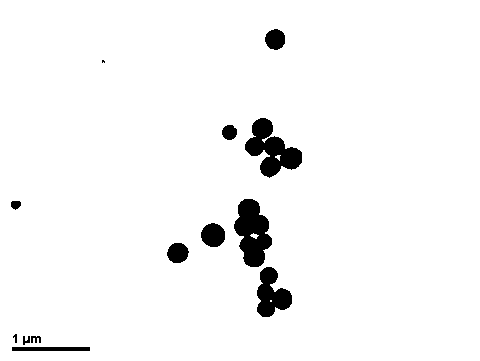

[0026] Dissolve sodium tripolyphosphate (TPP) in deionized water to prepare a 12.5 g / L sodium tripolyphosphate solution. Under the stirring of a magnetic stirrer, use a syringe to drop the sodium tripolyphosphate solution into the chitosan acetic acid solution drop by drop, the volume ratio of the chitosan acetic acid solution to the sodium tripolyphosphate solution is 3:2, keep stirring for 1h, Obtain suspension. Centrifuge the suspension liquid at high speed (3000r / min) for 15min in a high-speed centrifuge, filter the upper layer liquid, collect the lower layer sediment, and dry it in an oven at 37°C. The prepared chitosan microspheres have the following appearance: figure 1 shown.

[0027] Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O was dissolved in water and prepared as Ca(NO ...

Embodiment 2

[0031] Chitosan was dissolved in 166.7mM acetic acid solution to prepare 12.5g / L chitosan acetic acid solution. Regulate the pH value of chitosan acetic acid solution to be 5.0;

[0032] Dissolve sodium tripolyphosphate (TPP) in deionized water to prepare a 12.5 g / L sodium tripolyphosphate solution. Under stirring with a magnetic stirrer, use a syringe to drop the sodium tripolyphosphate solution into the chitosan acetic acid solution drop by drop, the volume ratio of the chitosan acetic acid solution to the sodium tripolyphosphate solution is 3:2, keep stirring for 1h, Obtain suspension. Centrifuge the suspension at a high speed (3000r / min) for 15 minutes in a high-speed centrifuge, filter off the upper layer, collect the lower layer of sediment, and dry it in an oven at 37°C to obtain chitosan microspheres;

[0033] Preparation of electrolyte: CaCl 2 Dissolved in water, formulated as CaCl with a calcium concentration of 80mM 2 aqueous solution, the NaH 2 PO 4 Dissolved...

Embodiment 3

[0037] Chitosan was dissolved in 166.7mM acetic acid solution to prepare 12.5g / L chitosan acetic acid solution. The pH value of regulating chitosan acetic acid solution is 6.0;

[0038] Dissolve sodium tripolyphosphate (TPP) in deionized water to prepare a 12.5 g / L sodium tripolyphosphate solution. Under stirring with a magnetic stirrer, use a syringe to drop the sodium tripolyphosphate solution into the chitosan acetic acid solution drop by drop, the volume ratio of the chitosan acetic acid solution to the sodium tripolyphosphate solution is 3:2, keep stirring for 1h, Obtain suspension. Centrifuge the suspension at a high speed (3000r / min) for 15 minutes in a high-speed centrifuge, filter off the upper layer, collect the lower layer of sediment, and dry it in an oven at 37°C to obtain chitosan microspheres;

[0039] Preparation of electrolyte: Ca(NO 3 ) 2 ·6H 2 O was dissolved in water and prepared as Ca(NO 3 ) 2 aqueous solution, the NH 4 h 2 PO 4 Dissolved in wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com