Coaxial homogeneous ZnO pn junction nanorod and preparation method thereof

A pn junction and nanorod technology, which is applied in the field of nanomaterial preparation, can solve the problems of inability to prepare ZnO coaxial and homogeneous pn junction nanorods, and achieve good application prospects, no environmental pollution, and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

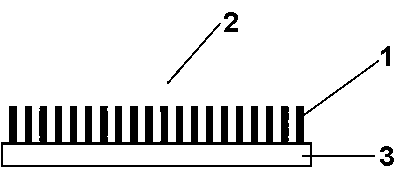

Image

Examples

Embodiment 1

[0022] The 5mM zinc nitrate solution and the 5mM hexamethylenetetramine solution were mixed at a volume ratio of 1:1 to a total of 150ml, and the mixed solution was heated to 80°C to obtain a zinc nitrate and hexamethylenetetramine mixed solution at 80°C.

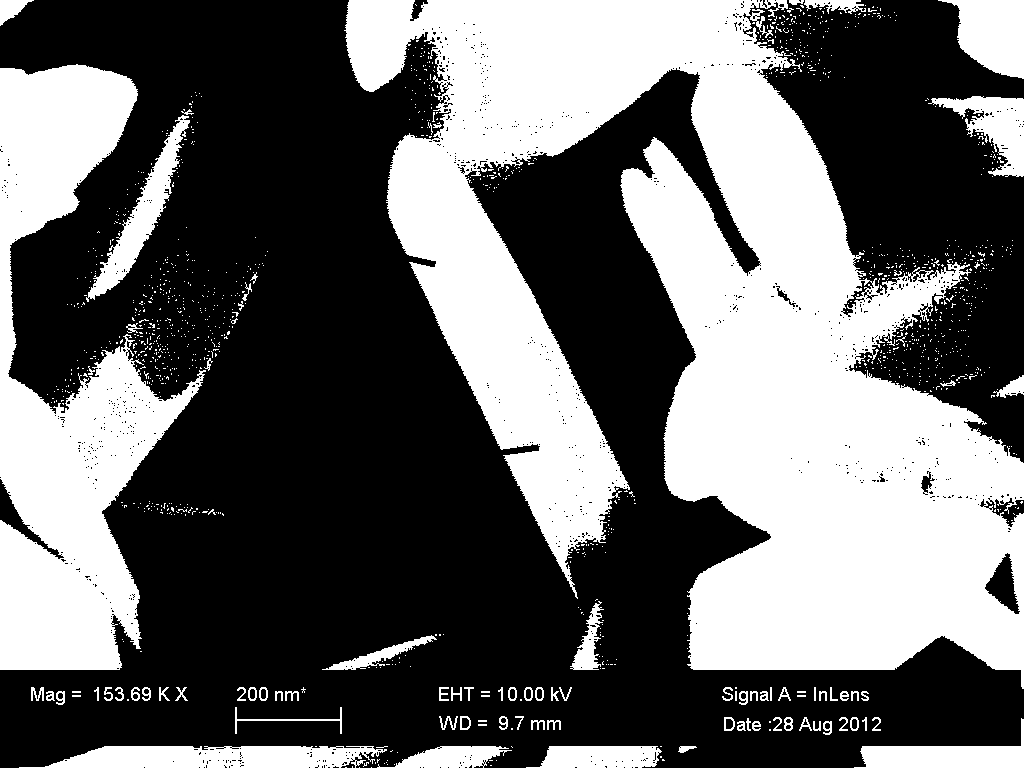

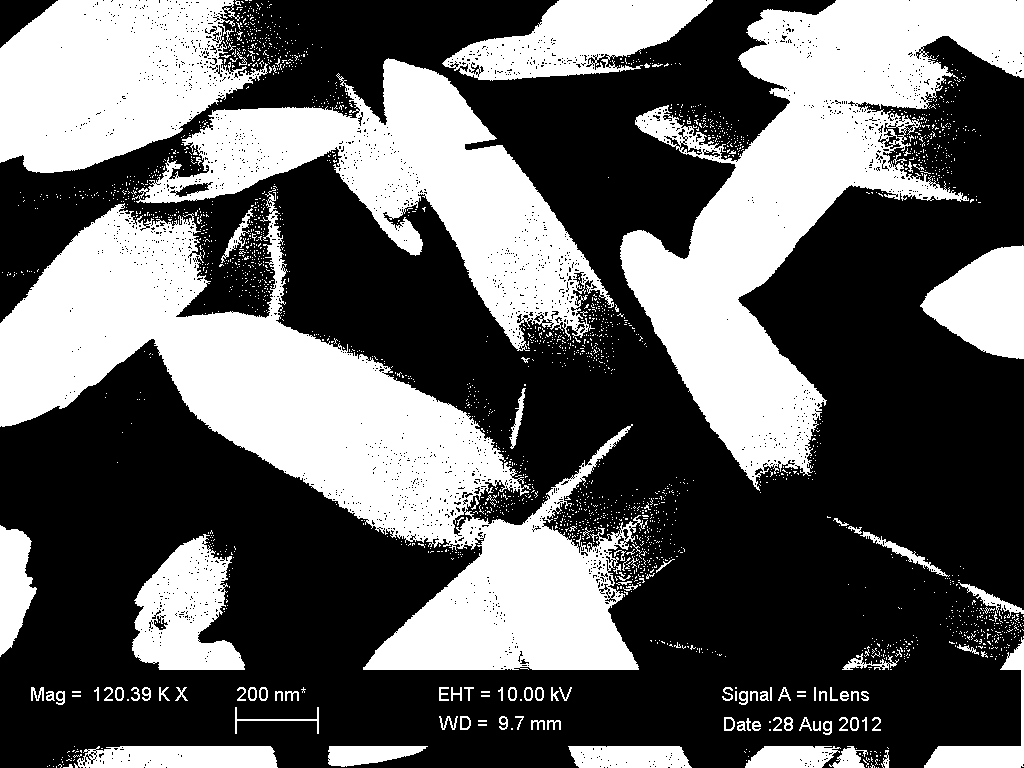

[0023]Immerse the working electrode 3 made of ITO conductive glass, the reference electrode made of Ag and AgCl and the counter electrode made of Pt together in a mixed solution of zinc nitrate and hexamethylenetetramine at 80 ° C, and the working electrode potential Adjust to -0.8V relative to the reference electrode, keep the potential of the reference electrode and the working electrode 3 for electrodeposition for 1 hour, and obtain undoped zinc oxide nanorods on the ITO conductive glass substrate, that is, the working electrode 3 Array, the undoped ZnO nanorods, that is, the undoped ZnO region 1 of the ZnO coaxial homogeneous pn junction nanorods is n-type, and then the working electrode 3 of the undoped ZnO nanorod arra...

Embodiment 2

[0029] The 5mM zinc nitrate solution and the 5mM hexamethylenetetramine solution were mixed at a volume ratio of 1:1 to a total of 150ml, and the mixed solution was heated to 80°C to obtain a zinc nitrate and hexamethylenetetramine mixed solution at 80°C.

[0030] Immerse the working electrode 3 made of ITO conductive glass, the reference electrode made of Ag and AgCl and the counter electrode made of Pt together in a mixed solution of zinc nitrate and hexamethylenetetramine at 80 ° C, and the working electrode potential Adjust to -0.85V relative to the reference electrode, keep the potential of the reference electrode and the working electrode 3 for electrodeposition for 1.5 hours, and obtain undoped zinc oxide nanorods on the ITO conductive glass substrate, that is, the working electrode 3 Array, the undoped ZnO nanorods, that is, the undoped ZnO region 1 of the ZnO coaxial homogeneous pn junction nanorods is n-type, and then the working electrode 3 of the undoped ZnO nanorod...

Embodiment 3

[0036] The 5mM zinc nitrate solution and the 5mM hexamethylenetetramine solution were mixed at a volume ratio of 1:1 to a total of 150ml, and the mixed solution was heated to 80°C to obtain a zinc nitrate and hexamethylenetetramine mixed solution at 80°C.

[0037] Immerse the working electrode 3 made of ITO conductive glass, the reference electrode made of Ag and AgCl and the counter electrode made of Pt together in a mixed solution of zinc nitrate and hexamethylenetetramine at 80 ° C, and the working electrode potential Adjust to -0.92V relative to the reference electrode, keep the potential of the reference electrode and the working electrode 3 for electrodeposition for 0.5 hours, and obtain undoped zinc oxide nanorods on the ITO conductive glass substrate, that is, the working electrode 3 Array, the undoped ZnO nanorods, that is, the undoped ZnO region 1 of the ZnO coaxial homogeneous pn junction nanorods is n-type, and then the working electrode 3 of the undoped ZnO nanorod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com