A laser measuring device for detecting liquid metal level

A liquid metal and laser measurement technology, applied in the direction of measuring devices, liquid/fluid solid measurement, lubrication indicator devices, etc., can solve the problems that cannot be used on a large scale, is not easy to install and maintain, and has high requirements for workers to operate. Compact structure, convenient installation and adjustment, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

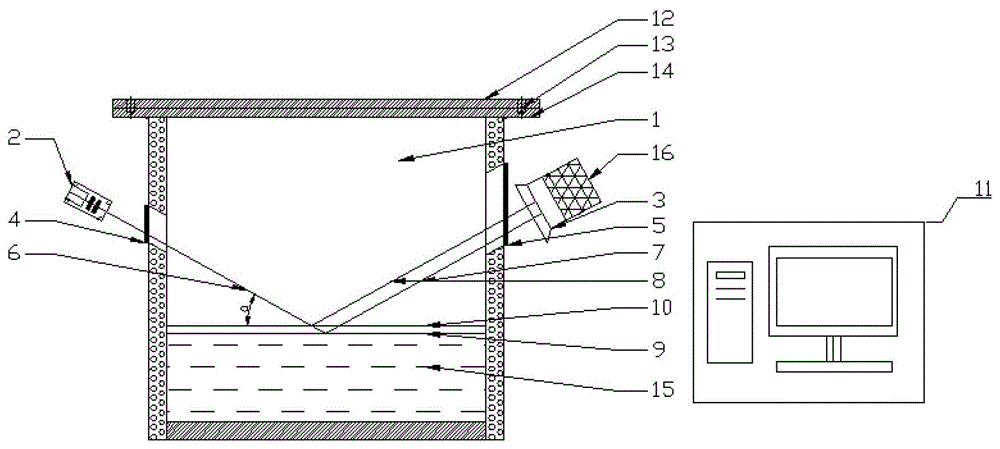

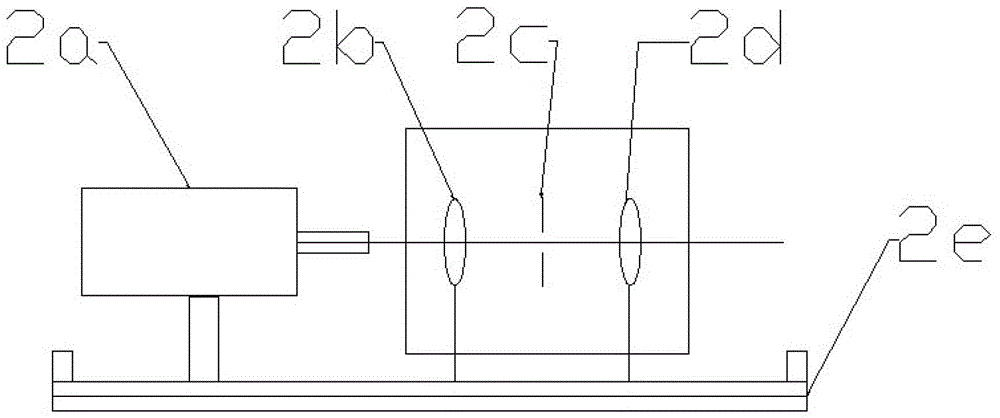

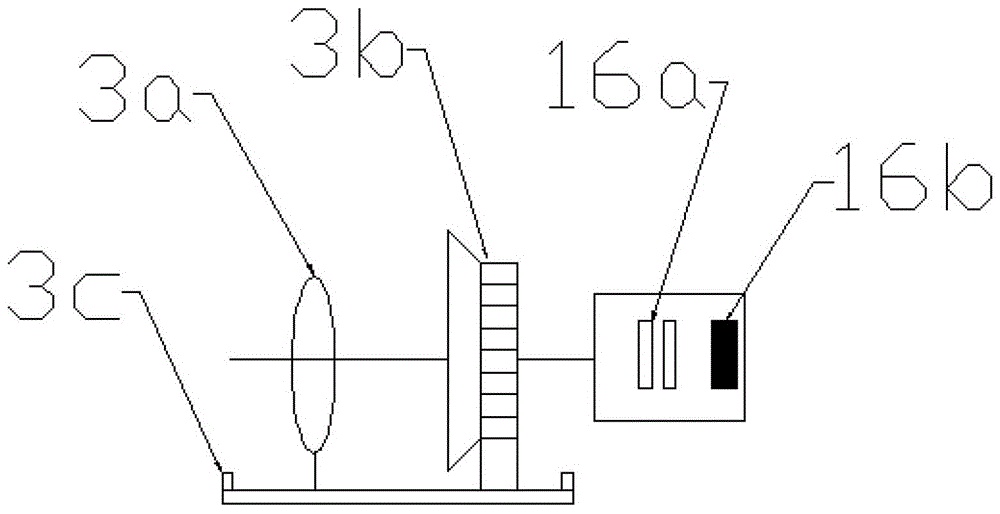

[0029] like figure 1As shown, a laser measuring device for detecting the liquid metal level includes a liquid metal tank 1, a laser emitting device 2, a laser reflection receiving device 3, a mid-end signal acquisition and processing part 16 and a computer 11; a liquid metal storage tank 1 is used to store liquid metal. Two windows are respectively opened on both sides of the metal storage tank 1, which are respectively the first glass window 4 for the incident laser beam 6 and the second glass window 5 for reflection, the first glass window 4 and the second glass window 5 for reflection. The second glass window 5 is sealed with a seal; the laser emitting device 2 is rigidly fixed at the position of the first glass window 4 on one side of the closed liquid metal storage tank 1, and the laser emitting device 2 includes a laser 2a, a beam expander lens 2b, and a pinhole filter. Laser 2a, beam expander lens 2b, pinhole filter 2c, and collimating objective lens 2d are placed in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com