Production process of cable for high-speed train

A production process and technology for high-speed trains, applied in cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve problems such as poor impact resistance and oil resistance, achieve enhanced impact resistance and shock resistance, and enhance mechanical softness Sexuality and flame retardancy, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A production process for cables for high-speed trains, comprising the following steps:

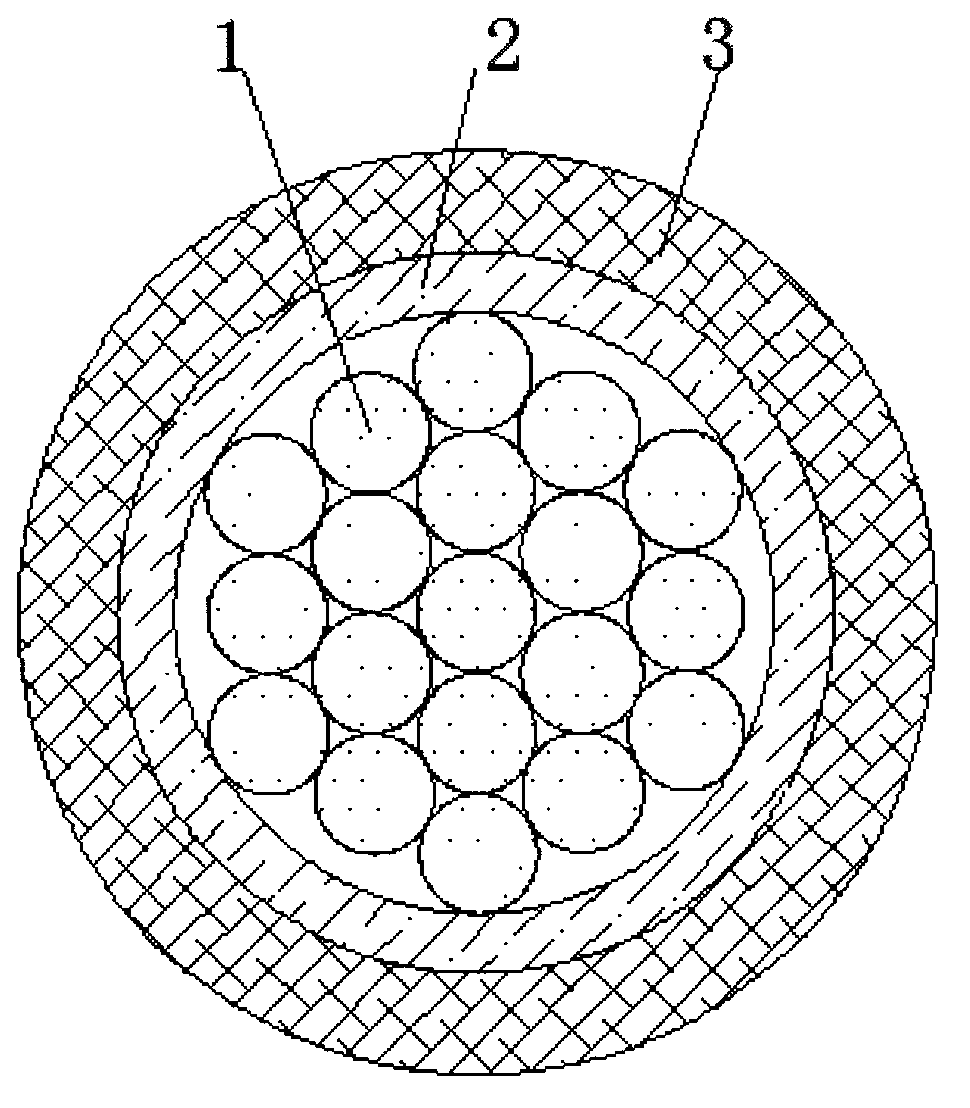

[0022] Step 1, using a plurality of thin tinned copper wires of the same diameter to be layered, multiple times, and stranded in the same direction to form a conductor cable core 1;

[0023] Step 2. Synchronously extrude the inner insulation layer 2 and the outer insulation layer 3 outside the conductor cable core 1 made in step 1. The inner insulation layer 2 is made of radiation cross-linked polyolefin material with high electrical performance, and the outer insulation layer 3 is made of high Irradiation cross-linked polyolefin materials with flame retardant properties;

[0024] The components and mass percentages of the inner insulating layer 2 are: cross-linkable polyolefin base material 50%, polymer plasticizer 23%, antioxidant 1%, sensitizer 25%, sensitizer 0.5% , magnesium hydroxide 0.5%;

[0025] The components and mass percentages of the outer insulating layer 3 are: 45% ...

Embodiment 2

[0027] A production process for cables for high-speed trains, comprising the following steps:

[0028] Step 1, using a plurality of thin tinned copper wires of the same diameter to be layered, multiple times, and stranded in the same direction to form a conductor cable core 1;

[0029] Step 2. Synchronously extrude the inner insulation layer 2 and the outer insulation layer 3 outside the conductor cable core 1 made in step 1. The inner insulation layer 2 is made of radiation cross-linked polyolefin material with high electrical performance, and the outer insulation layer 3 is made of high Irradiation cross-linked polyolefin materials with flame retardant properties;

[0030] The components and mass percentages of the inner insulating layer 2 are: cross-linkable polyolefin base material 55%, polymer plasticizer 20%, antioxidant 1%, sensitizer 23%, sensitizer 0.5% , Phosphate 0.5%;

[0031] The components and mass percentages of the outer insulating layer 3 are: 50% cross-link...

Embodiment 3

[0033] A production process for cables for high-speed trains, comprising the following steps:

[0034] Step 1, using a plurality of thin tinned copper wires of the same diameter to be layered, multiple times, and stranded in the same direction to form a conductor cable core 1;

[0035] Step 2. Synchronously extrude the inner insulation layer 2 and the outer insulation layer 3 outside the conductor cable core 1 made in step 1. The inner insulation layer 2 is made of radiation cross-linked polyolefin material with high electrical performance, and the outer insulation layer 3 is made of high Irradiation cross-linked polyolefin materials with flame retardant properties;

[0036] The components and mass percentages of the inner insulating layer 2 are: 55% of cross-linkable polyolefin base material, 20% of polymer plasticizer, 1% of alkyl polyphenol material, 23% of TMPTM, 0.5% of carbon black, Magnesium hydroxide 0.5%;

[0037] The components and mass percentages of the outer ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com