Processing method of tea with reserved caffeine and functional food fabricated by tea

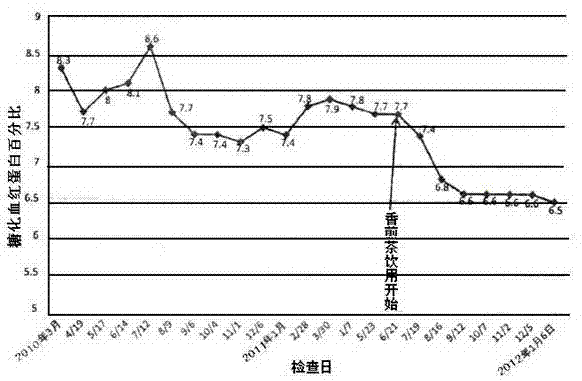

A processing method, caffeine technology, applied in the direction of tea extraction, etc., can solve the problems of lack of practicability and achieve the effect of improving kidney function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Set up the pressure-resistant heating device, the temperature of the first stage is 100°C, the temperature of the second stage is 125°C, and the heating time of the second stage is 30 minutes. Spread 10kg of raw tea in layers, put 5 layers into the container, and close the pressure container The door is blown into the pressurized steam, so that the pressurized and humidified steam is evenly distributed to each layer of raw tea, so that it is evenly heated, and the leaf alcohol and leaf aldehyde contained in the raw tea and the excess steam Discharge from the exhaust port, close the exhaust valve when the temperature reaches the first stage temperature, conduct uniform heating treatment at the second stage temperature of 125°C, close the heating steam valve when the second stage heating is completed, and open the exhaust valve to make the pressure vessel become For normal pressure, open the container door, take out the tea and move it to the drying device to dry the proce...

Embodiment 2

[0034]50kg of raw tea, 1kg of water, and 500g of calcium carbonate are evenly stirred. The temperature of the first stage is 100°C, the temperature of the second stage is 115°C, and the heating time of the second stage is 30 minutes. Enter the pressurized steam, so that the pressurized and humidified steam is evenly spread to each layer of the raw tea for heating, and the leaf alcohol and leaf aldehyde components contained in the raw tea and the excess steam are discharged from the exhaust port When the temperature reaches the first stage temperature, close the exhaust valve to isolate from the outside, and heat to the second stage temperature of 115°C for heating. Because the temperature is controlled by adjusting the steam pressure in the container, different from the normal pressure tea fire, each layer of tea is heated evenly at 115°C. After the second stage of heating, close the steam valve, open the exhaust valve, make the pressure-resistant container become normal pres...

Embodiment 3

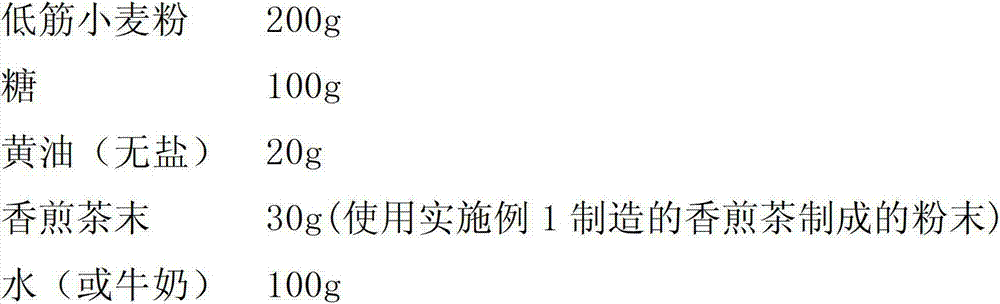

[0038] Prepare the following materials for making snacks

[0039]

[0040] Mix the above ingredients, put the stirred biscuit ingredients into the mold, and bake in a pot at 150°C for 8 minutes. Compared with other snacks made with green tea powder, this kind of snack has less astringency and can be made to maintain the fragrance of fried tea. Biscuits with sex ingredients.

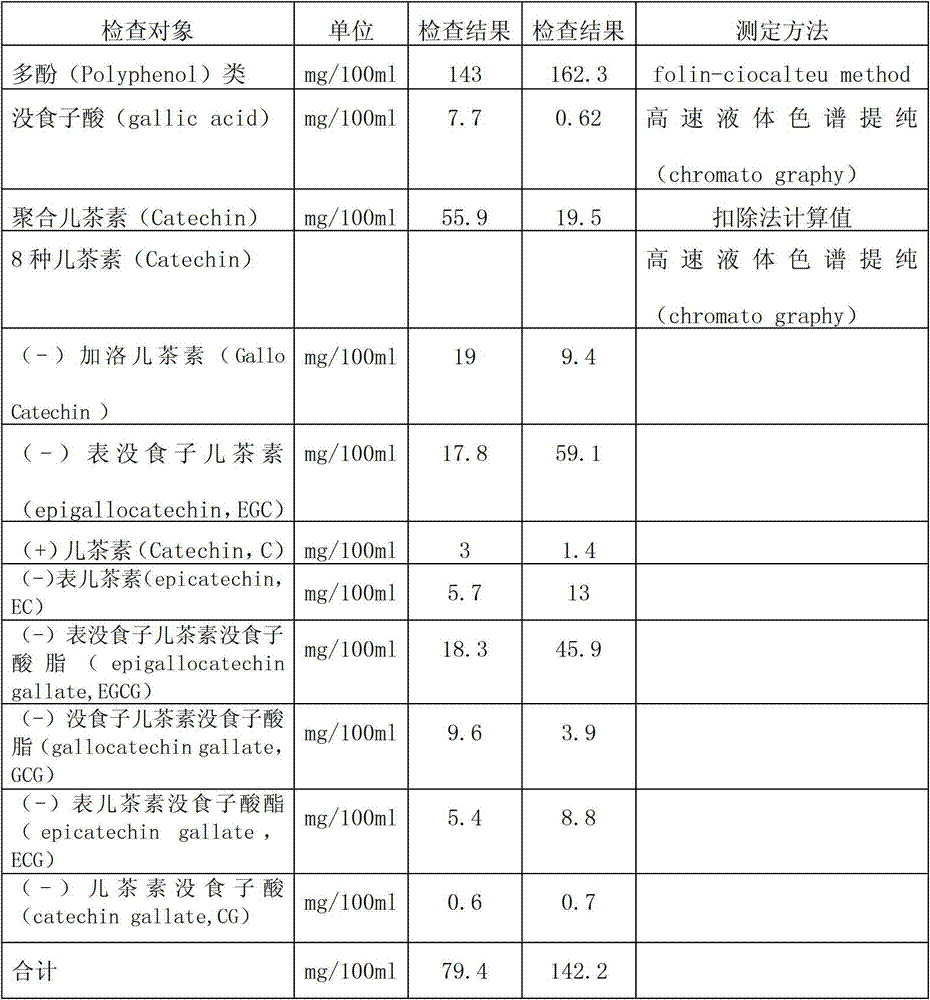

[0041] The analysis results of catechins and polyphenols before and after processing of Xiangsencha are shown in the table below:

[0042] Fried processed green tea raw material green tea

[0043]

[0044] Extraction conditions: Add 3g of tea leaves to 200ml of boiling water for 5 minutes and then analyze the extract

[0045] Polyphenol (polyphenol) is a mixture of most polymer polyphenols (polyphenol), which cannot be analyzed directly. All polyphenols (polyphenol) are analyzed by (folin-phenol) folin-ciocalteu method, and purified according to high-speed liquid chromatography ( chromatograph) D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com