Method for controlling anaerobic digestion of easily-degradable organic wastes through utilizing intermittent micro-aeration

An anaerobic digestion and organic waste technology, applied in the field of resources and environment, can solve problems such as many pipelines and unfavorable equipment maintenance, and achieve the effects of maintaining stable operation, reducing pressure, and reducing the concentration of organic acids and ammonia nitrogen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

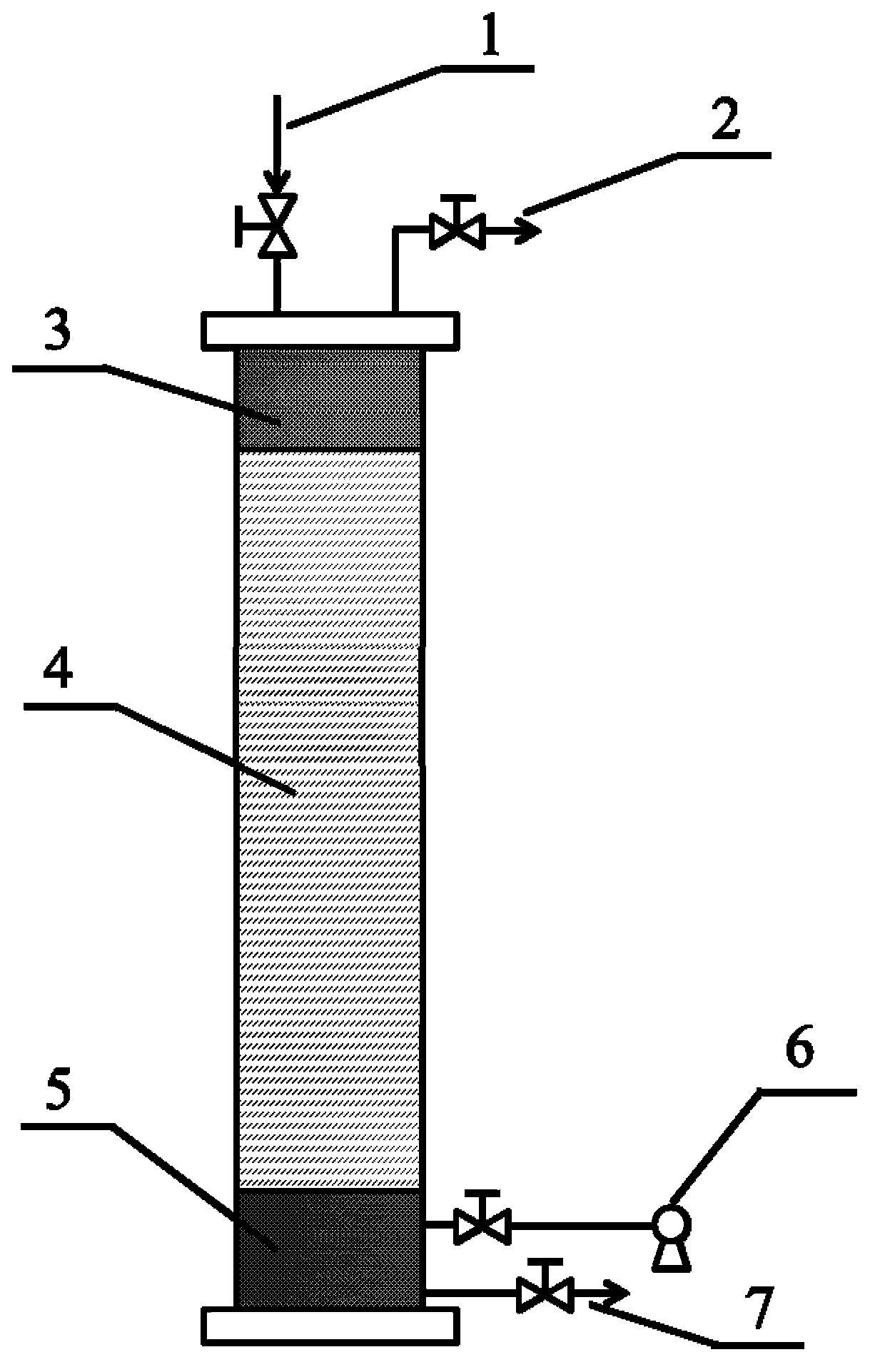

[0033] The form of the anaerobic digestion reactor in this embodiment is a simulated landfill column, and the simulated column is a PVC plastic cylinder with a diameter of 400 mm and a height of 2300 mm. Test device such as figure 1 As shown, the recharge leachate inlet 1 and the biogas outlet 2 are both set at the upper end of the simulated landfill column, and the inside of the simulated landfill column is the water distribution layer 3, the pile body 4 and the leachate diversion layer 5 in sequence from top to bottom. The micro-aeration equipment 6 and the leachate outlet 7 are both arranged at the lower end of the simulated landfill column. The proportion of kitchen waste in the filling materials in the simulated column is 84%, and the rest of the materials are refractory and non-degradable substances. The total filling mass is 145kg, and the compacted density is 0.80t / m 3 , the moisture content is 75%. The temperature inside the simulated column was controlled at 30±5°C...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the micro-aeration group starts forced ventilation from the 7th week, and aerates 4 times a day, each time for 5 minutes, and the average daily aeration amount per cubic meter of easily degradable organic waste 0.51m 3 , other parameters and implementation are the same as in Example 1. The test results show that the first column (completely anaerobic) produces no biogas, the pH of the leachate is always less than 6.0, the COD concentration is as high as 60g / L, and a large part is organic acid. The second column (intermittent micro-aeration group) did not perform intermittent micro-aeration in the first 7 weeks, and the leachate index was similar to that of the first column, and no biogas was produced. After micro-aeration in the column from the 7th week, the pH of the reaction system rose to 6.0 on the 13th day, and the COD in the leachate dropped to below 5g / L on the 29th day. The biogas production and t...

Embodiment 3

[0039] The difference between this example and Example 1 is that the COD concentration in the recharge leachate of the intermittent micro-aeration group increased to 60±5g / L after 100 days. Other parameters and implementation are the same as in Example 1. The test results show that the biogas production has increased slightly, and the methane content in the biogas has been stable above 50%. The COD in the leachate has been lower than 5g / L, and the pH has been maintained above 6.0. These test results show that intermittent micro-aeration can be used as a daily adjustment method to maintain the stable operation of the reaction system when the organic load in the anaerobic digestion system fluctuates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com