Method for preparing 3-pentanone and propanal through using H2, CO and ethylene

A technology of ethylene and pentanone is applied in the field of preparing 3-pentanone and propionaldehyde to achieve the effect of reducing reaction pressure and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

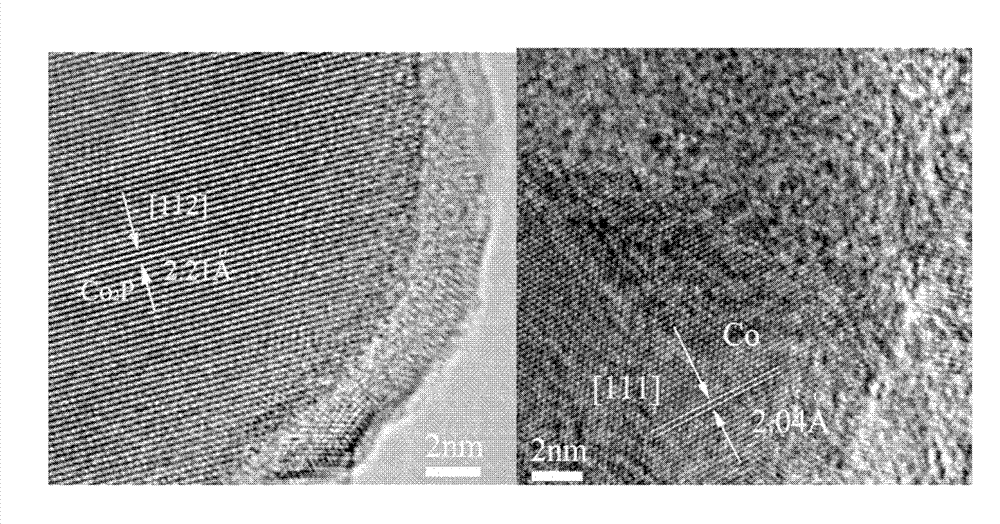

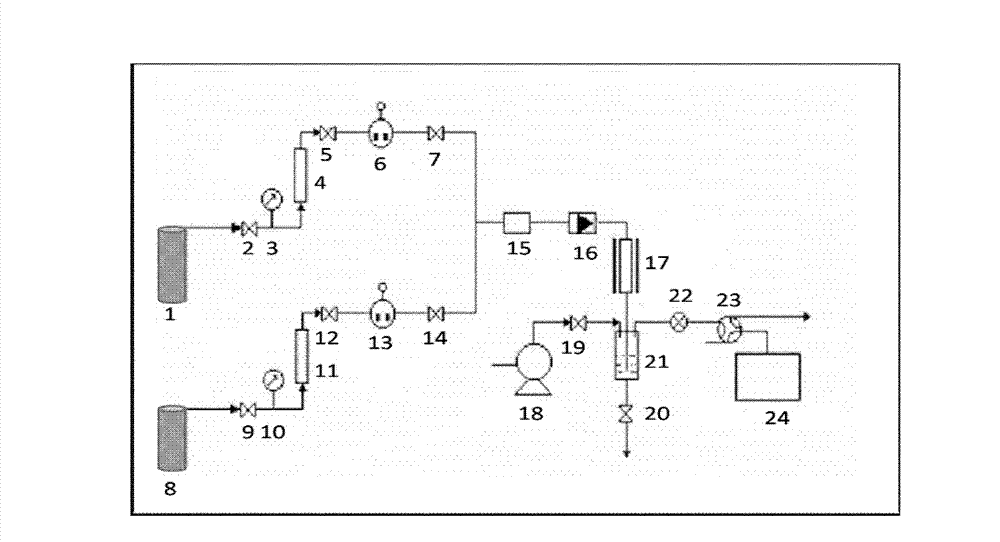

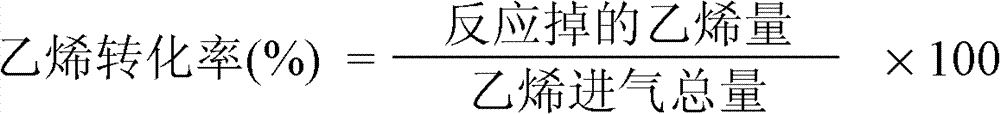

[0019] The catalyst used is 0.9%K-15%Co-0.66%P / coconut shell activated carbon (Co / P=12 molar ratio). The weight composition of the catalyst is: Co=15%, K=0.9%, P=0.66%, and the rest is carrier activated carbon. The carrier adopts commercial coconut shell carbon, and the catalyst active components Co and P and the auxiliary agent K are loaded on the carrier activated carbon by conventional impregnation method. Specifically, weigh 10.0 grams of coconut shell charcoal (20-40 mesh, BET specific surface area: 1135m 2 / g, the average pore size is 21nm), the configuration 8ml contains 7.80 grams of Co(NO 3 ) 2 .6H 2 O, 0.3 g (NH 4 ) 2 HPO 4 and 0.216 g KNO 3 aqueous solution, drop about 2ml of concentrated HNO 3 , heat to dissolve, impregnate the coconut shell charcoal carrier with this aqueous solution, dry in a water bath at 60°C, and dry in an oven at 80°C for 8 hours. Before the precursor of the above-mentioned catalyst is used, take 5ml (3.4 grams) of the above-mentione...

Embodiment 2

[0026] The catalyzer that adopts is that 5%K-25%Co-1.1%P / almond kernel charcoal (Co / P=12 mol ratio) is catalyzer, and other conditions are identical with embodiment 1.

Embodiment 3

[0028] Adopting reaction temperature is 100 ℃, other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com