Manufacturing method of chlorinated rubber paint

A kind of technology of chlorinated rubber paint and production method, applied in the direction of rubber derivative paint, coating, epoxy resin paint, etc., can solve the problems of hard texture, easy dust accumulation, sticky dust and other problems of real stone paint, and achieve good weather resistance resin , good water resistance and convenient construction

Inactive Publication Date: 2013-05-08

张秀华

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] There are many paints on the market at present, which have great disadvantages. 1. Peeling, the paint film contains gravel particles with large self-weight, and the film thickness is much thicker than that of ordinary latex paint. Real stone paint film and wall surface often appear The adhesion is not firm and there is a phenomenon of partial falling off

2. Whitening in case of rain, the traditional real stone paint is soaked in rainwater for 2 hours, and the milk saponification effect occurs. After the sun comes out, the saponified white emulsion is sealed in the paint film emulsion, causing the paint film part to turn white, which affects the solemnity of the imitation stone. Effect

3. Yellowing due to sun exposure. Traditional real stone paint emulsions (such as styrene-acrylic, acrylic emulsions) contain a large number of benzene rings, which produce a color effect after being exposed to the sun, that is, the benzene rings are decomposed by light and turn yellow, which again affects the decoration of imitation stone. Effect

4. Cracking. The traditional real stone paint is hard, but hard is not tough. With the cracking of the base layer of the wall, part of the paint film of the real stone paint is also cracked, which is extremely unfavorable to the wall decoration effect.

5. Pollution, because the surface of the real stone paint film is often rough, so it is easy to accumulate dust, vacuum, stick to dust and other pollution. If you observe carefully, you will find that the traditional real stone paint is on the wall for half a year to a year. It will not fall off, even if it is washed, it will not be cleaned, which will give a certain discount to the decorative effect of imitation stone

6. Fading, traditional real stone paint is often made of pigment sintered sand, long-term light will fade (color paste aging and decomposition)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

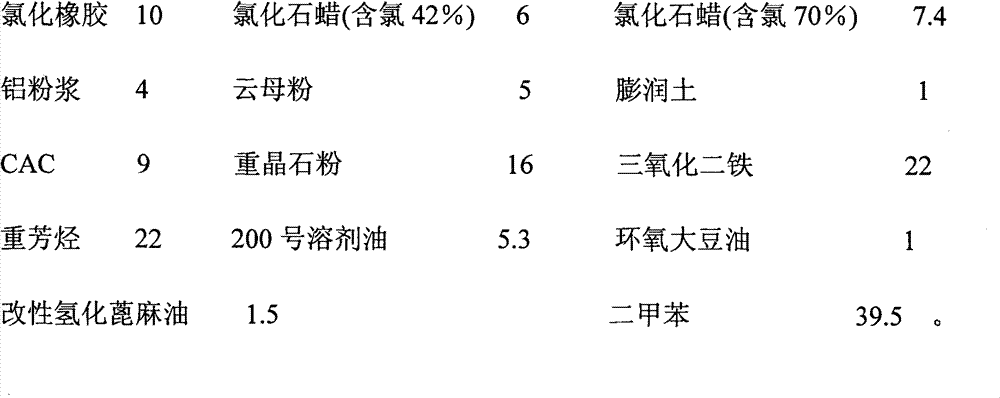

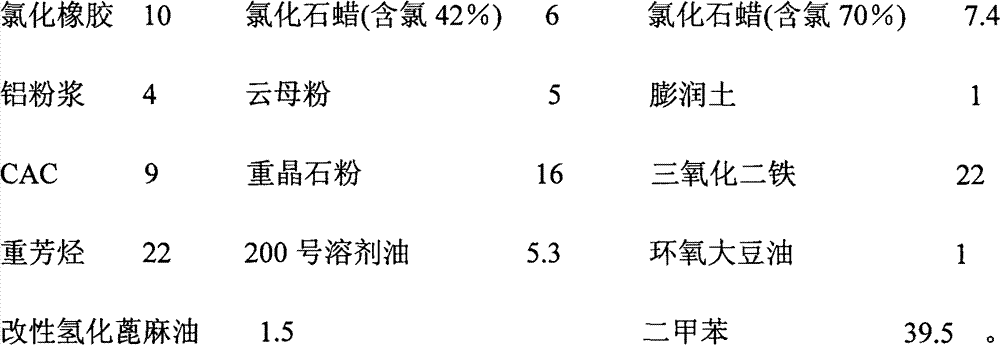

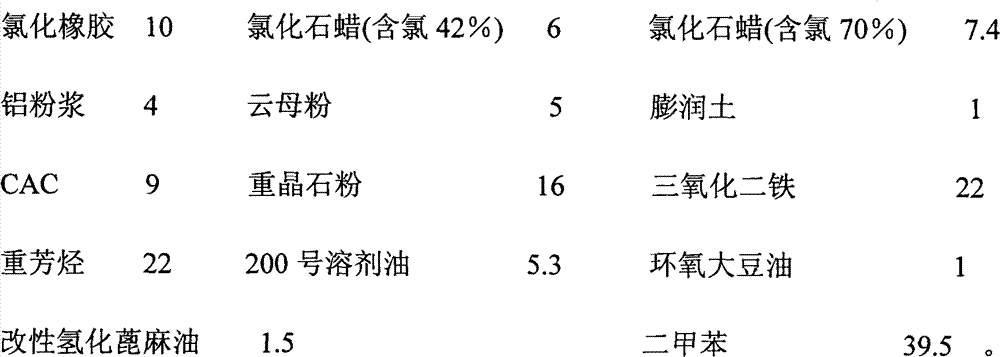

[0008] The present invention is realized by following technical scheme: a kind of preparation method of chlorinated rubber paint is characterized in that: used raw material has

[0009]

[0010] Production of chlorinated rubber After kneading, cut into small pieces, add epoxy resin, add solvent xylene, glue: solution = 1:4~5, mix with room temperature, stir for 10 hours, and filter to obtain the finished product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a manufacturing method of rubber paint and especially relates to a manufacturing method of chlorinated rubber paint. The chlorinated rubber paint has strong adhesion to metals and nonmetals, can be dried fast, is convenient for construction, has a highly saturated structure, good weatherability, good ultraviolet resistance, good acid and alkali resistance, good solvent resistance, oil resistance, water resistance, good cold resistance and good temperature toleration, can be used at a temperature of -50 to +120 DEG C, has ozone resistance, aging resistance, a good color, pollution resistance, good elasticity and punching and wear resistance, and prevents wet, salt spray and mould.

Description

technical field [0001] The invention relates to a method for making rubber paint, in particular to a method for making chlorinated rubber paint. Background technique [0002] There are many paints on the market at present, which have great disadvantages. 1. Peeling, the paint film contains gravel particles with large self-weight, and the film thickness is much thicker than that of ordinary latex paint. Real stone paint film and wall surface often appear The adhesion is not firm and there is a phenomenon of partial falling off. 2. Whitening in case of rain, the traditional real stone paint is soaked in rainwater for 2 hours, and the milk saponification effect occurs. After the sun comes out, the saponified white emulsion is sealed in the paint film emulsion, causing the paint film part to turn white, which affects the solemnity of the imitation stone. Effect. 3. Yellowing due to sun exposure. Traditional real stone paint emulsions (such as styrene-acrylic, acrylic emulsions...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D115/02C09D163/00C09D7/12

Inventor 张秀华

Owner 张秀华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com