Insulating heat conduction high-temperature resistant electrical appliance coating and preparation method thereof

A technology of insulation and heat conduction and high temperature resistance, which is applied in the field of insulation, heat conduction and high temperature resistant electrical coatings and its preparation, which can solve problems such as easy cracking, brittle coatings, and unstudied thermal conductivity, and achieve good thermal conductivity and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

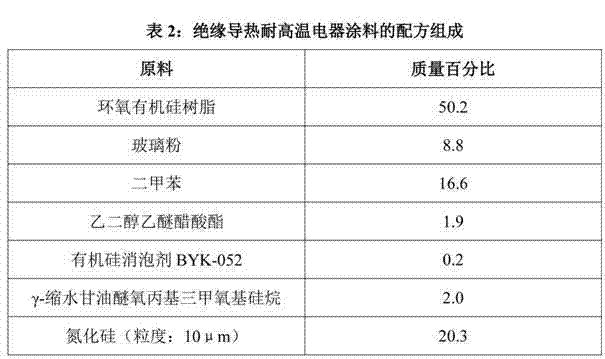

[0024] An insulating, heat-conducting, and high-temperature-resistant electrical appliance coating, its formula composition is as follows in Table 1:

[0025]

[0026] The preparation method of the insulating, heat-conducting and high-temperature-resistant electrical coating is as follows: during preparation, weigh the raw materials according to the above formula, use a high-speed disperser at a speed of 800-1000 rpm, stir and disperse for 30 minutes, then use a sand mill to grind for 20-50 minutes, and finally The 100-mesh filter screen is filtered to obtain an insulating, heat-conducting, and high-temperature-resistant electrical appliance coating.

[0027] Spray the paint on the tinplate, first cured at 80°C for 15 minutes, then cured at 180°C for 10 minutes, the thickness of the paint film is 100 microns, the adhesion of the paint film is grade 1, and the hardness is 2H; the breakdown voltage is 2050 volts / 0.5 mA, 2 seconds; the heat transfer coefficient is 1.3W / (m 2 ·...

Embodiment 2

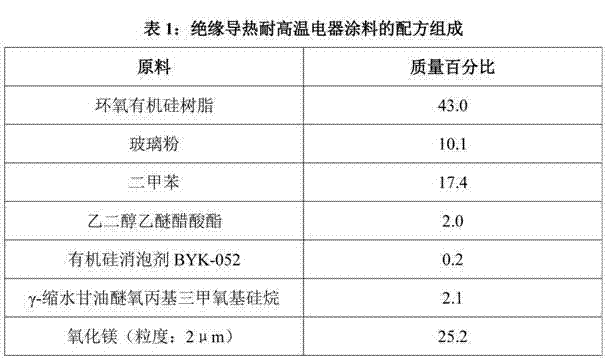

[0031] An insulating, heat-conducting, and high-temperature-resistant electrical appliance coating, its formula composition is as follows in Table 2:

[0032]

[0033] The preparation method of the insulating, heat-conducting and high-temperature-resistant electrical coating is as follows: during preparation, weigh the raw materials according to the above formula, use a high-speed disperser at a speed of 800-1000 rpm, stir and disperse for 30 minutes, then use a sand mill to grind for 20-50 minutes, and finally The 100-mesh filter screen is filtered to obtain an insulating, heat-conducting, and high-temperature-resistant electrical appliance coating.

[0034] Spray the paint on the tinplate, first cured at 80°C for 15 minutes, then cured at 180°C for 10 minutes, the thickness of the paint film is 100 microns, the adhesion of the paint film is grade 1, and the hardness is 2H; the breakdown voltage is 2100 volts / 0.5 mA, 2 seconds; the heat transfer coefficient is 1.6W / (m 2 ·...

Embodiment 3

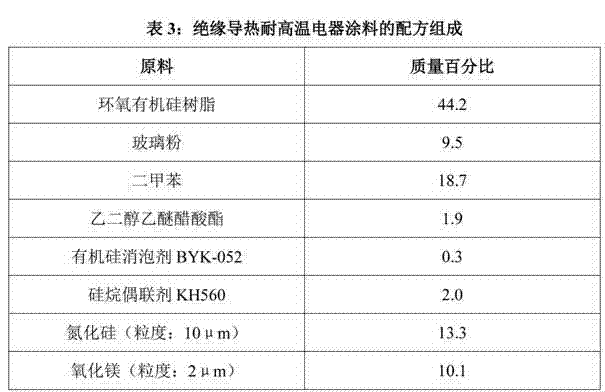

[0038] An insulating, heat-conducting, and high-temperature-resistant electrical appliance coating, its formula composition is as follows in Table 3:

[0039]

[0040] The preparation method of the insulating, heat-conducting and high-temperature-resistant electrical coating is as follows: when preparing, weigh the raw materials according to the above formula, use a high-speed disperser to disperse them evenly, and then use a sand mill to grind for 20-50 minutes, and filter through a 100-mesh filter to prepare Insulation, heat conduction and high temperature resistant electrical coating.

[0041] The paint is sprayed on the tinplate, cured at 80°C for 15 minutes, then cured at 180°C for 10 minutes, the thickness of the paint film is 100 microns, the adhesion of the paint film is grade 1, and the hardness is 2H; the breakdown voltage is 2010 volts / 0.5 mA, 2 seconds; the heat transfer coefficient is 1.4W / (m 2 ·K); 250°C constant temperature for 48 hours, the paint film is smoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com