Cerium-ion-doped silicate blue fluorescent powder and preparation method thereof

A blue phosphor and silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of InGaN chip matching, easy agglomeration of phosphor powder, high synthesis temperature, etc., and achieve chromaticity and photometric stability Good, cheap and easy to get raw materials, good development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

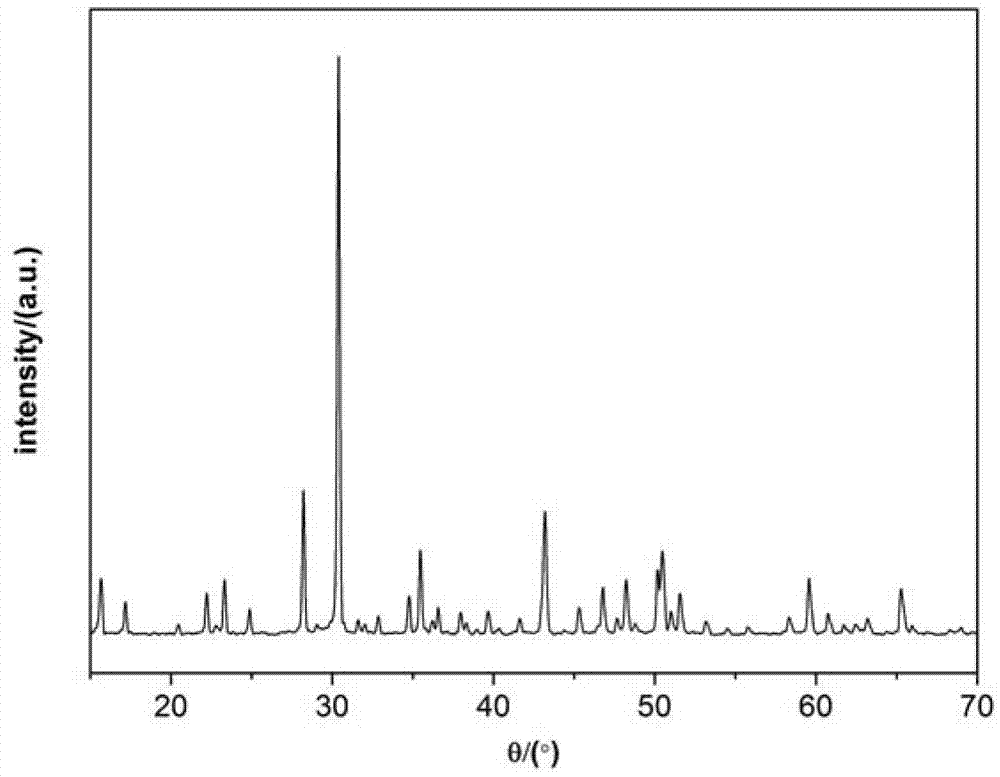

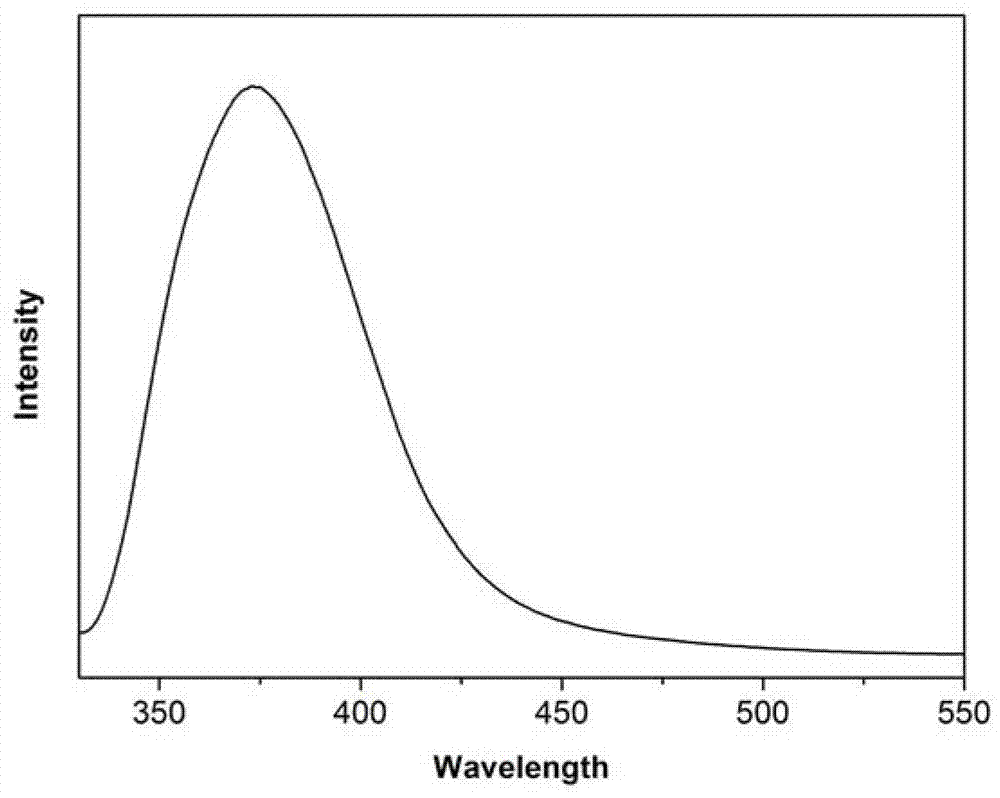

[0023] According to Sr 1.9999 MgSi 2 o 7 : 0.0001Ce 3+ The stoichiometric ratio of each element, accurately weighed analytically pure SrCO 3 , MgO, SiO 2 , CeO 2 and H 3 BO 3 Put it in an agate mortar, add a small amount of alcohol to grind for 30~60min, H 3 BO 3 with SrCO 3 The molar ratio is 0.03:1. After drying at 60~120°C, continue to grind for 10 minutes, then place it in a crucible at 1100°C for 48 hours, wait for the temperature to drop to room temperature, take out the product, crush it, grind it, and classify it to get The blue phosphor to be prepared.

Embodiment 2

[0025] According to Sr 1.99 MgSi 2 o 7 : 0.01Ce 3+ The stoichiometric ratio of each element, accurately weighed analytically pure SrCO 3 , MgO, SiO 2 , CeO 2 and H 3 BO 3 Put it in an agate mortar, add a small amount of alcohol to grind for 30~60min, H 3 BO 3 with SrCO 3 The molar ratio is 0.01:1. After drying at 60~120°C, continue to grind for 10 minutes, then place it in a crucible at 1200°C for 24 hours, wait for the temperature to drop to room temperature, take out the product, crush it, grind it, and classify it to get The blue phosphor to be prepared.

Embodiment 3

[0027] According to Sr 1.97 MgSi 2 o 7 : 0.03Ce 3+ The stoichiometric ratio of each element, accurately weighed analytically pure SrCO 3 , MgO, SiO 2 , CeO 2 and H 3 BO 3 Put it in an agate mortar, add a small amount of alcohol to grind for 30~60min, H 3 BO 3 with SrCO 3 The molar ratio is 0.05:1. After drying at 60~120°C, continue to grind for 10 minutes, then place it in a crucible at 1250°C for 12 hours, wait for the temperature to drop to room temperature, take out the product, crush it, grind it, and classify it to get The blue phosphor to be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com