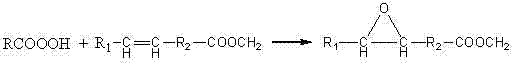

Method for preparing epoxidized fatty acid methyl ester through lipase catalysis

A technology of epoxy fatty acid methyl ester and fatty acid methyl ester, which is applied in the field of plasticizers, can solve the problems of harsh reaction conditions, toxic by-products, environmental pollution, etc., and achieve the effects of less by-products, high epoxy value, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

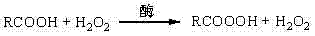

[0025] (1) Preparation of urea hydrogen peroxide

[0026] Start stirring with 25% hydrogen peroxide solution and 1.0g stabilizer EDTA. After it is completely dissolved, add urea. The molar ratio of hydrogen peroxide to urea is 1:1. Under constant stirring, heat up to 30°C. Completely dissolve urea, keep it warm for 20 minutes, cool to minus 5°C for crystallization, filter with suction, and dry at 50°C for 2 hours to obtain the urea peroxide product.

[0027] (2) Preparation of epoxy fatty acid methyl ester

[0028] Mix 100g of fatty acid methyl ester, 10g of formic acid and 3g of lipase Novozym435 evenly, stir and heat up to 30°C for reaction, then add urea hydrogen peroxide with a mass concentration of 25% in 3 times, each time adding 20g, react for 10h, and react The product is introduced into the separator, left to stand for stratification, and the upper organic phase is taken with Ca(OH) 2 Adjust the pH value to 6.5 and dry to obtain epoxy fatty acid methyl ester.

Embodiment 2

[0030] (1) Preparation of urea hydrogen peroxide

[0031] Start stirring with 30% hydrogen peroxide solution and 2.0g stabilizer EDTA. After it is completely dissolved, add urea. The molar ratio of hydrogen peroxide to urea is 1:1. Under constant stirring, heat up to 35°C. Completely dissolve urea, keep it warm for 30 minutes, cool to minus 5°C for crystallization, filter with suction, and dry at 50°C for 2 hours to obtain the urea peroxide product.

[0032] (2) Preparation of epoxy fatty acid methyl ester

[0033] Mix 100g of fatty acid methyl ester, 20g of formic acid and 4g of lipase Novozym435 evenly, stir and raise the temperature to 35°C for reaction, then add urea hydrogen peroxide with a mass concentration of 30% in 4 times, each time adding 15g, react for 9 hours, and react The product was introduced into a separator, allowed to stand for stratification, and the upper organic phase was taken to adjust the pH value to 7.0 with KOH, and dried to obtain epoxy fatty ...

Embodiment 3

[0035] (1) Preparation of urea hydrogen peroxide

[0036] Start stirring with 50% hydrogen peroxide solution and 2.0g stabilizer EDTA. After it is completely dissolved, add urea. The molar ratio of hydrogen peroxide to urea is 1:1. Under constant stirring, heat up to 35°C. Completely dissolve urea, keep it warm for 30 minutes, cool to minus 5°C for crystallization, filter with suction, and dry at 50°C for 2 hours to obtain the urea peroxide product.

[0037] (2) Preparation of epoxy fatty acid methyl ester

[0038] Mix 100g of fatty acid methyl ester, 30g of formic acid and 5g of lipase Novozym435 evenly, stir and heat up to 40°C for reaction, then add urea hydrogen peroxide with a mass concentration of 50% in 4 times, each time adding 10g, react for 8 hours, and then react The product was introduced into a separator, allowed to stand for stratification, and the upper organic phase was taken to adjust the pH value to 7.5 with NaOH, and dried to obtain epoxy fatty acid met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com