A kind of preparation method of metal oxide semiconductor nanometer material

A technology of oxide semiconductors and nanomaterials, applied in the field of inorganic nanomaterials, can solve problems such as insufficient product purity and complex processes, and achieve the effects of high product purity, simple experimental equipment requirements, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

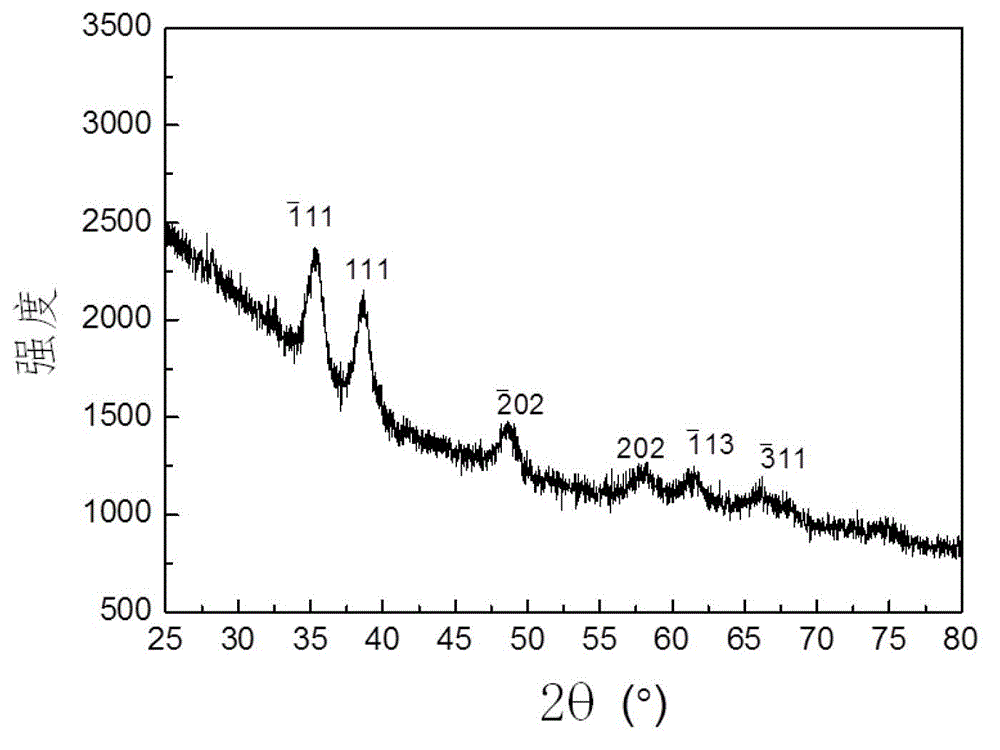

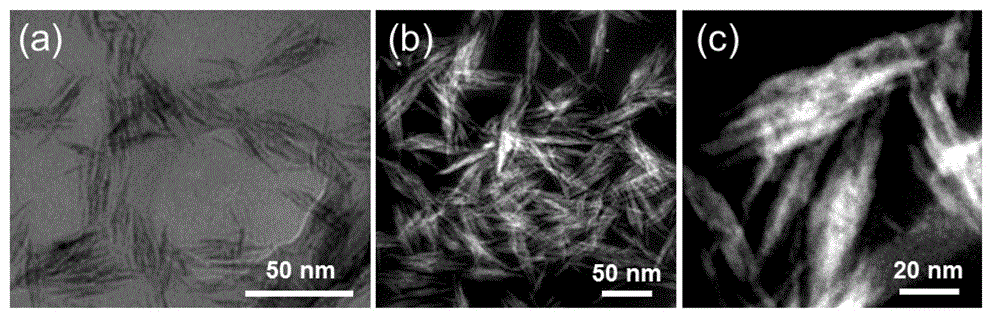

[0029] Example 1 Preparation of beam-shaped copper oxide nanomaterials

[0030] 1) Preparation of copper electrode pairs

[0031] Select two copper rods with a diameter of 2mm and a length of 10mm, put an alumina insulating tube (inner diameter 2mm, outer diameter 3mm) on the two copper rods, and then fix them in a Teflon tube (inner diameter 3mm) to obtain a copper reaction electrode . Install the above-mentioned copper reaction electrode on the glass container through the hole on the container wall in a horizontally opposite position. The distance between the electrode pairs is fixed at 0.2mm, and the angle between the electrode pairs is fixed at 180°. Connect a pulsed DC power supply (model MPP- HV03, Japan Co., Ltd. Kurita Manufacturing Co., Ltd.) to form a discharge circuit.

[0032] 2) Preparation of beam-like copper oxide nanomaterials

[0033] Add 120ml of distilled water into a 150ml glass container to ensure that the copper electrode pair is submerged in water and...

Embodiment 2

[0037] Example 2 Preparation of flower cluster zinc oxide nanomaterials

[0038] 1) Preparation of zinc electrode pair:

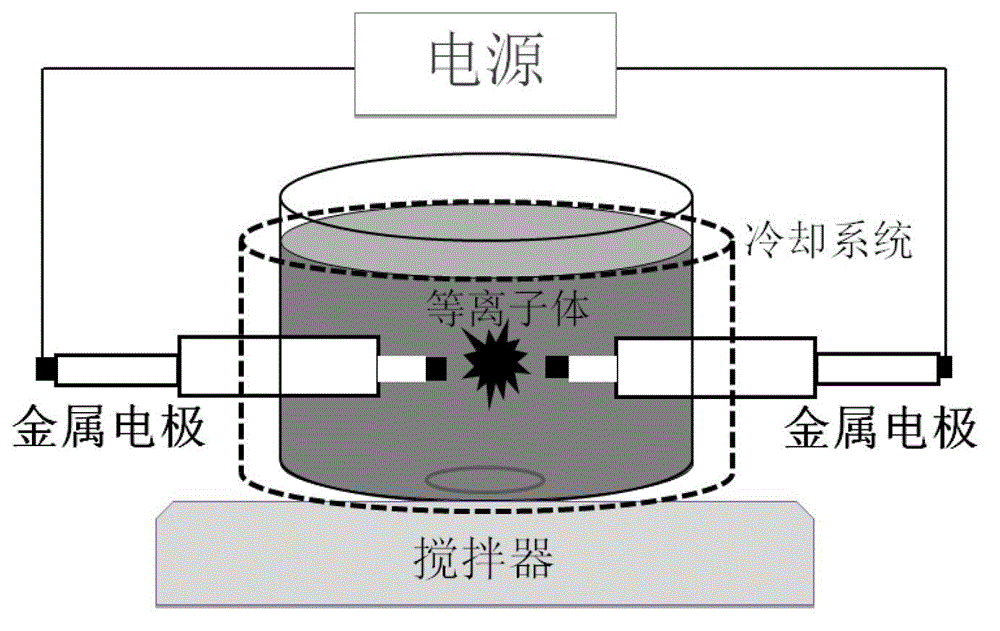

[0039] Select two zinc wires with a diameter of 1mm and a length of 10mm, put an aluminum oxide insulating tube (inner diameter 1mm, outer diameter 2.5mm) on the two zinc wires, and then fix them in a Teflon tube (inner diameter 2.5mm) to obtain zinc Reactive electrodes. Install the above-mentioned zinc reaction electrode on the glass container through the hole on the container wall in a horizontally opposite position, the distance between the electrode pairs is fixed at 0.2mm, the angle between the electrode pairs is fixed at 180°, and a pulsed DC power supply (model MPP- HV03, Japan Co., Ltd. Kurita Manufacturing Co., Ltd.) to form a discharge circuit. Then if figure 1 Place the glass container in a room temperature water bath as indicated.

[0040] 2) Preparation of flower cluster ZnO nanomaterials

[0041]Add 120ml of distilled water into a 150ml g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com