Multi-cylinder electro-hydraulic control system for double-valve-core rotary type direction throttle valve control cylindrical valve

An electro-hydraulic control system, rotary technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problem that it is difficult to achieve high precision without overspeed protection device and flyaway shutdown function Control, control system complexity and other issues, to avoid unknown dead zone and zero drift, high-precision mechanical hydraulic electrical synchronous control, system simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

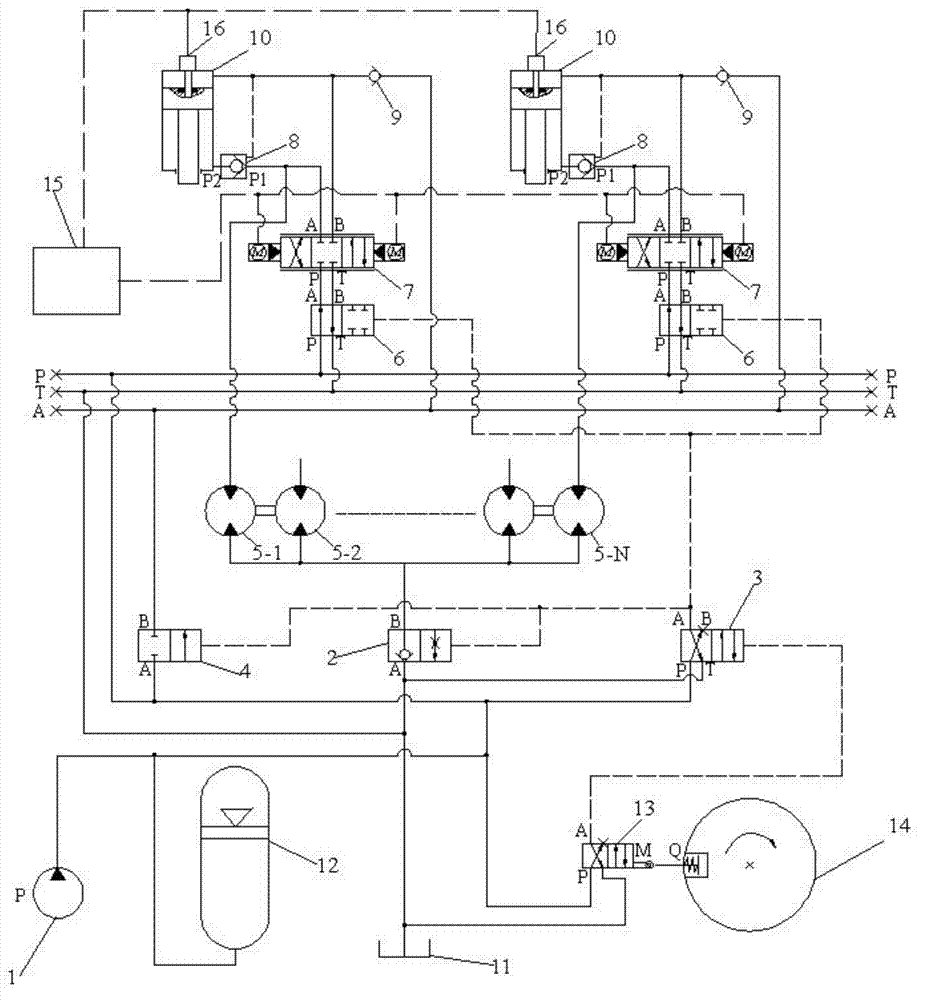

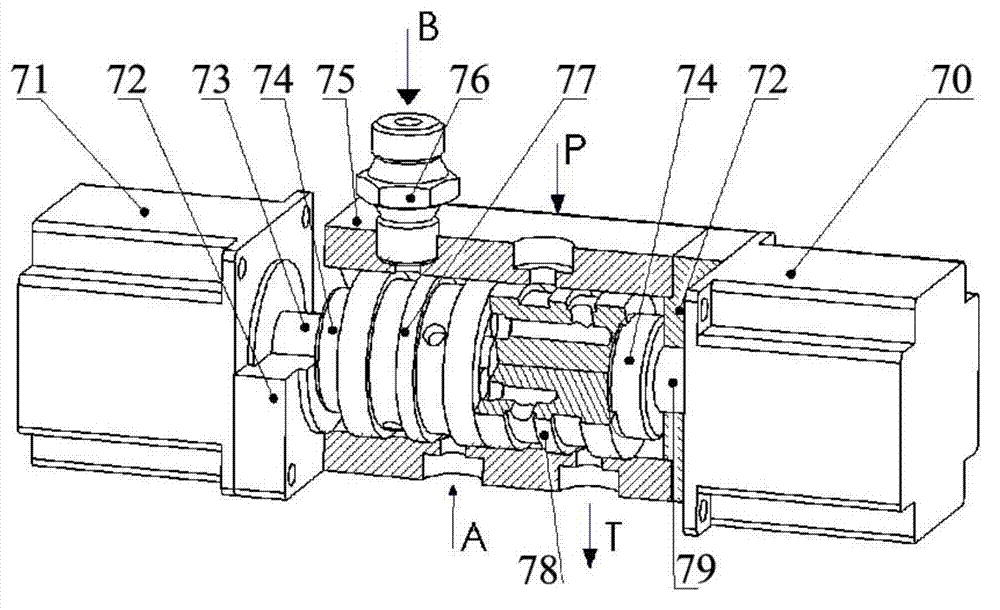

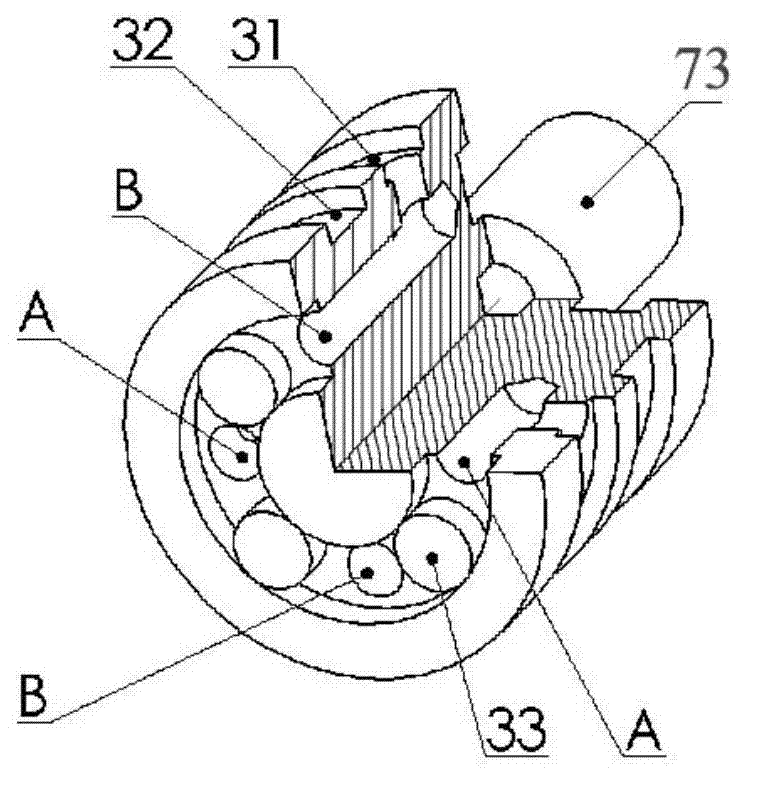

[0030] see Figure 1 to Figure 7 , a dual-spool rotary directional throttle valve control barrel valve multi-cylinder electro-hydraulic control system, including a plurality of hydraulic cylinders 10 connected to the barrel valve, the upper chamber of each hydraulic cylinder 10 rotates with the double spool Type directional throttle valve 7 is connected, and the lower cavity of each hydraulic cylinder is connected with the double-spool rotary directional throttle valve 7 through a hydraulic control check valve 8, and the control of the hydraulic control check valve 8 The oil port is connected to the oil inlet pipe of the upper chamber of the hydraulic cylinder 10, the P2 port of the hydraulic control check valve 8 is connected to the lower ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com