Process for performing desulphurization by using slag of circulating fluidized bed boiler

A technology of circulating fluidized bed and fluidized bed boiler, which is applied in the directions of fluidized bed combustion equipment, fuels burned in a molten state, chemical instruments and methods, etc. , to achieve the effect of saving calcium powder, great advancement and economy, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

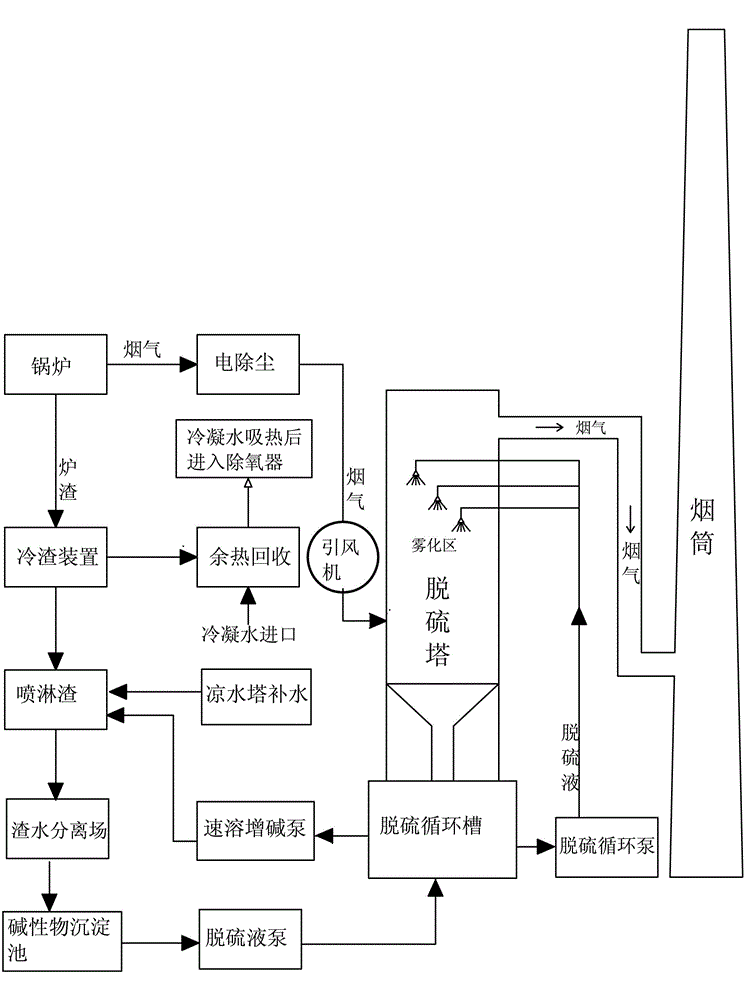

[0019] Process flow of the present invention such as figure 1 shown.

[0020] 1. Principle and process flow of slag desulfurization:

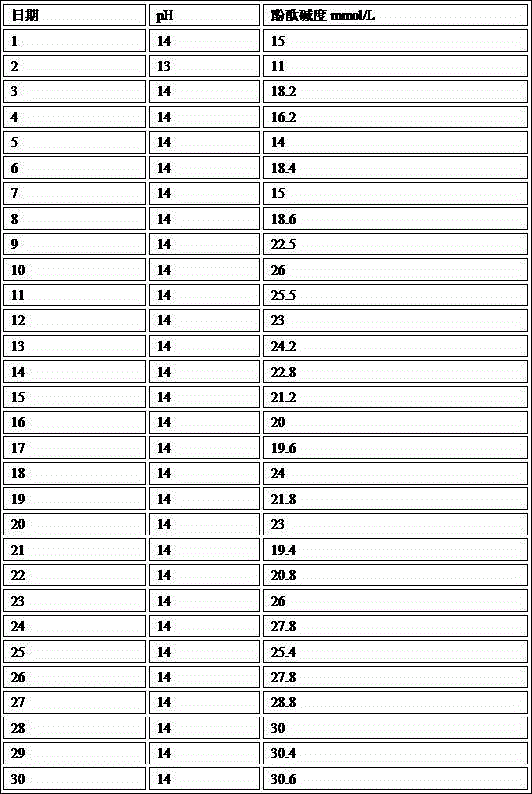

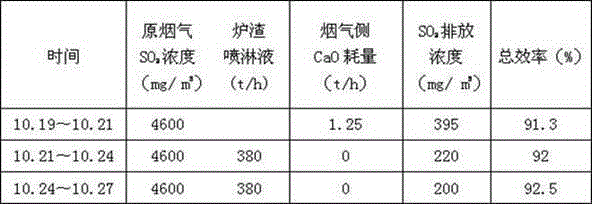

[0021] 1. The fuel for the circulating fluidized bed boiler is coal gangue with a calorific value of 2000-2200kcal / kg. The main chemical composition of this coal gangue is: CaCO 3 Content 44.86%, MgCO 3 Content 11.66%, AlCO 3 Content 5.5%, NaCO 3 The content is 1.0%, and the Si content is 22%. After blending, it is crushed into particles with a particle size of 0-10mm and enters the boiler for combustion, and the hearth temperature is controlled at 900-980°C. CaCO 3 , MgCO 3 、AlCO 3 Generate CaO, MgO, AlO, etc. and CO at high temperature 2 . The boiler needs normal and continuous slag removal. The slag is discharged into the slag cooling device at 900-980°C for water injection and spraying to cool down. The low-pressure and high-temperature steam generated enters the waste heat recovery device. The water is heated to 90°C±5°C and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com