Organic silicon emptying tail gas purification and recovery treatment system and method

A tail gas purification and recovery treatment technology, which is applied in the field of purification and separation treatment, absorption, washing, methyl chlorosilane venting tail gas condensation, can solve the problems of strong acidity of the vented air, difficult treatment and operation, environmental pollution, etc., and achieve easy large-scale production , Avoid environmental risks, simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A device for cooling, washing, absorbing and separating organosilicon exhaust gas. Under laboratory conditions, methyl chlorosilane is used as the absorption solvent, and the absorption solvent is cooled, and the temperature is controlled below -5°C. The organosilicon vent gas is absorbed by deep cooling, washing, and first-level gas-liquid separation. Methyl chlorosilane The monomer is dissolved in the solvent, and after the gas phase tail gas is incinerated, there is no obvious silica powder, and the removal rate of the vent tail gas is 96%, which can meet the requirements of rectification vent and synthesis vent gas.

Embodiment 2

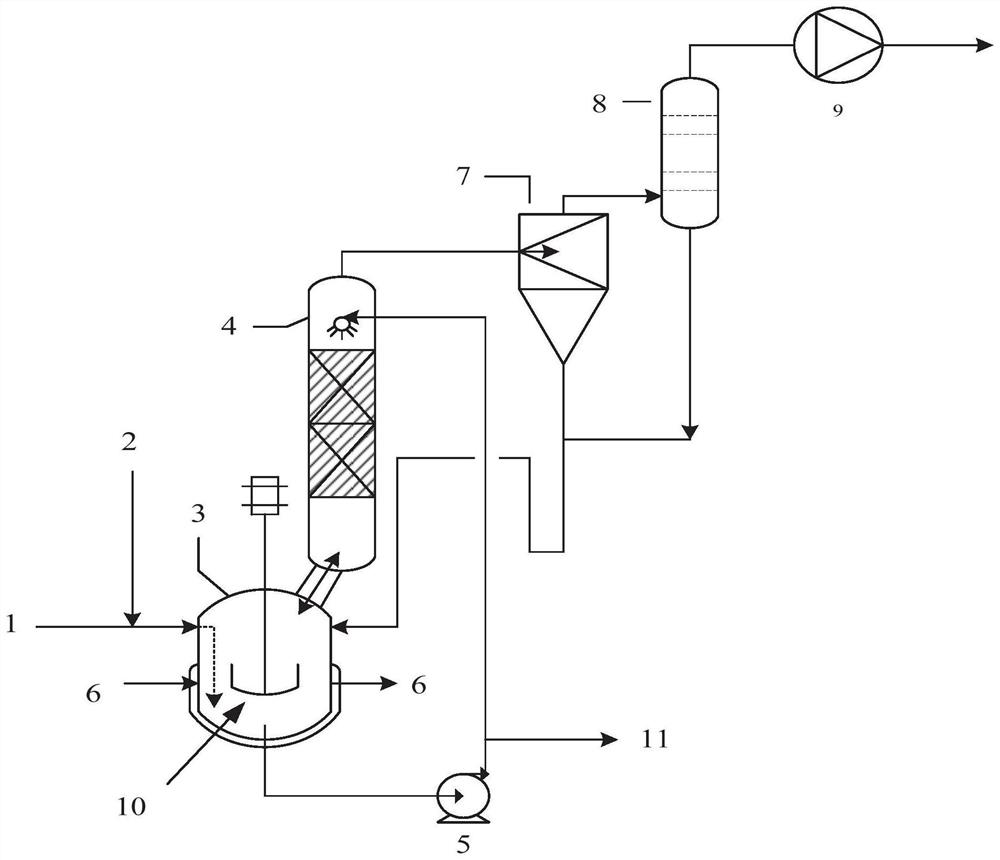

[0034] A device for cleaning, absorbing, purifying, separating, and recovering organic silicon vent gas. The organic silicon vent gas scrubbing, absorbing, purifying, separating, and recovering device is designed and manufactured by itself, including: agitating washing tank 3, washing and absorbing tower 4, and washing cycle Pump 5, refrigerant system 6, crude primary gas-liquid separator 7, precision secondary demister 8, air induction facility 9, washing absorption liquid 10, washing liquid absorption replacement pipeline 11, etc. realize the purification and separation of organic silicon exhaust gas. Under the condition of slightly positive pressure, add an absorption solvent 1 (methyl chlorosilane monomer), after cryogenic treatment in the refrigerant system 6, control the temperature below -5°C, and control the washing circulation pump according to the exhaust volume of rectification tail gas and synthesis tail gas 5 washing volume, to ensure that the vented tail gas is ef...

Embodiment 3

[0036] A device for washing, absorbing, purifying, separating, and recovering organic silicon exhaust gas. The organic silicon exhaust gas washing, absorption, purification, separation, and recovery device is designed and manufactured by itself, including: stirring and washing tank 3, washing and absorbing tower 4, and washing cycle Pump 5, refrigerant system 6, coarse primary gas-liquid separator 7, precise secondary demister 8, air induction facility 9, washing absorption liquid 10, washing liquid absorption replacement pipeline 11, etc., realize the purification and separation of organic silicon exhaust gas. Under the condition of slightly positive pressure, add an absorption solvent 2 (dimethyldichlorosilane), after cryogenic treatment in the refrigerant system 6, control the temperature below -25°C, and control the washing circulation pump according to the exhaust volume of rectification tail gas and synthesis tail gas 5 washing volume, to ensure that the vented tail gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com