Lithium borohydride/rare earth magnesium base alloy composite hydrogen storage material and preparation method thereof

A technology of lithium borohydride and hydrogen storage materials, which is applied in the field of lithium borohydride/rare earth magnesium-based alloy composite hydrogen storage materials and its preparation, can solve problems such as complicated operation, unsuitable for large-scale sample preparation, and difficult to meet practical applications. Achieve the effect that the preparation method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the alloy composition ratio, the rare earth elements and metals were prepared in the form of simple substances. 0.3 Mg 0.7 Ni 3.2 co 0.2 mn 0.2 Al 0.2 Alloy, the purity of the raw material is above 99.5%. The prepared raw material is vacuumed to 0.05Pa in a vacuum quenching furnace, and then protected by argon, smelted and thrown into a hydrogen storage alloy sheet of 0.05~0.10mm. The alloy sheet is 900 Heat treatment at ℃ for 4 hours, after cooling, ball milling, passing through a 200-mesh sieve to obtain hydrogen storage alloy powder with a particle size of less than 0.08mm. The obtained alloy is flaked alloy.

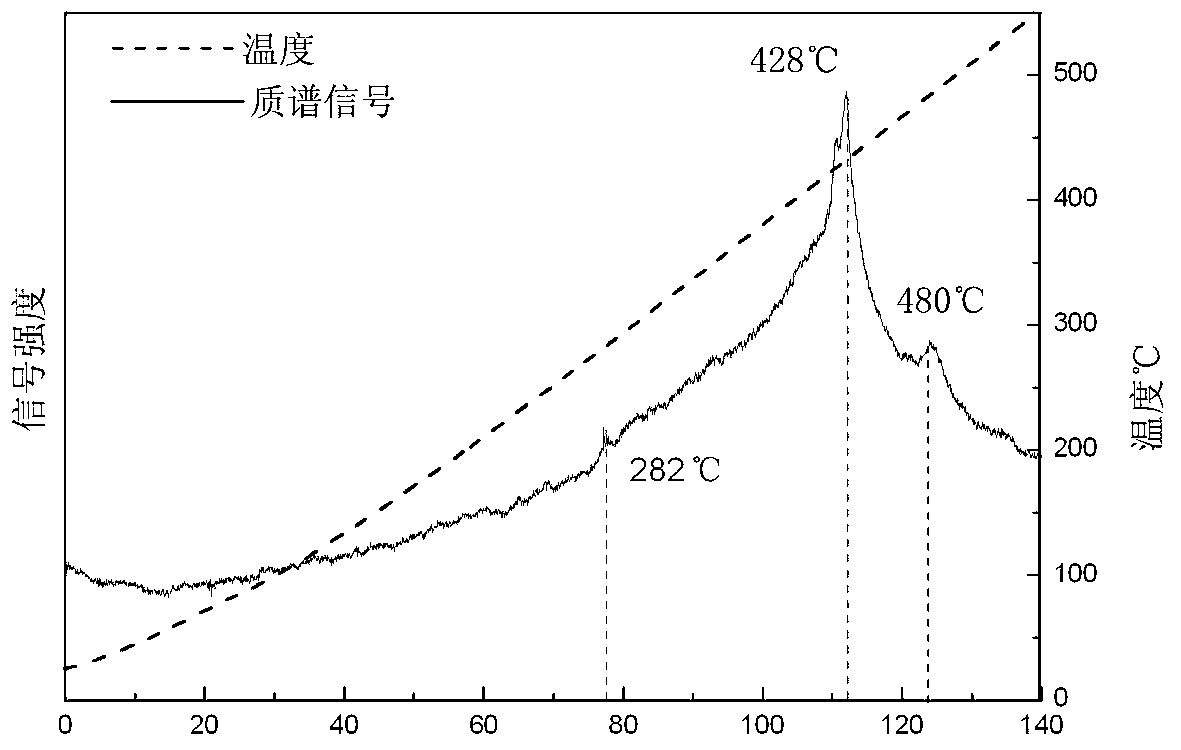

[0019] Commercially available LiBH 4 La 0.3 Mg 0.7 Ni 3.2 co 0.2 mn 0.2 Al 0.2 After the alloy is mixed according to the mass ratio of 4:1, add the heptane solution according to the ratio of the total mass of the mixed powder (g): the volume of the solution (ml) = 1:1, ball mill for 24 hours under the protection of argon, and freeze-dr...

Embodiment 2

[0023] Rare earth elements and metals are prepared in the form of simple substances according to the alloy composition ratio 0.5 Mg 0.4 Ni 3 co0.5 mn 0.4 Al 0.4 Alloy, the purity of the raw material is above 99.5%. The prepared raw material is vacuumed to 0.05Pa in a vacuum quenching furnace, and then protected by argon, smelted and thrown into a hydrogen storage alloy sheet of 0.05~0.10mm. The alloy sheet is 800 Heat treatment at ℃ for 6 hours, after cooling, ball milling, passing through a 200-mesh sieve to obtain hydrogen storage alloy powder with a particle size of less than 0.08mm. The obtained alloy powder was hydrogenated under a hydrogen pressure of 3 MPa to obtain a hydrogenated alloy.

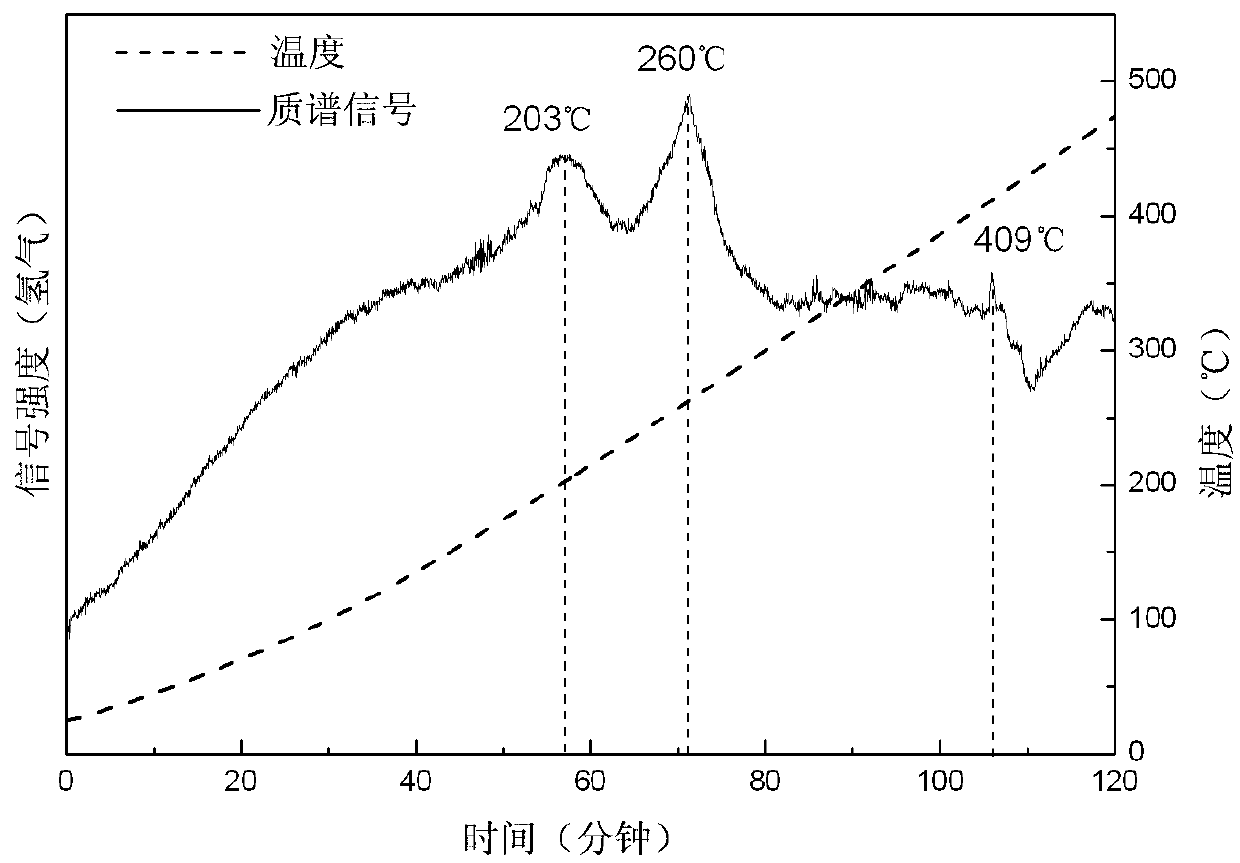

[0024] Commercially available LiBH 4 After the powders are mixed at a mass ratio of 1:1, add 3ml of hexane solution according to the ratio of the total mass of the mixed powder (g): solution volume (ml) = 1:3, ball mill for 24 hours under the protection of argon, and test after f...

Embodiment 3

[0026] Rare earth elements and metals are prepared in the form of simple substances according to the alloy composition ratio 0.8 Mg 0.2 Ni 2.8 co 0.8 mn 0.3 Al 0.1 Alloy, the purity of the raw material is above 99.5%, the prepared raw material is vacuumed to 0.05Pa in a vacuum quenching furnace, then protected by argon gas, the pressure is about 0.05MPa, melted and thrown into a hydrogen storage alloy sheet of 0.05~0.10mm , the alloy flakes were heat treated at 1000°C for 2 hours, after cooling, they were milled into powder and passed through a 200-mesh sieve to obtain hydrogen storage alloy powder with a particle size of less than 0.08mm, and the obtained alloy was flaked alloy.

[0027] Commercially available LiBH 4 After the powders were mixed in a mass ratio of 1:4, 1ml of tetrahydrofuran solution was added according to the ratio of total mass of mixed powder (g): solution volume (ml) = 1:2, ball milled for 24 hours under the protection of argon, and tested after free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com