Material capable of controlling slow release of fertilizer

A technology of slow-release fertilizer and carbon material, applied in the field of new materials, materials for controlling slow-release of fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

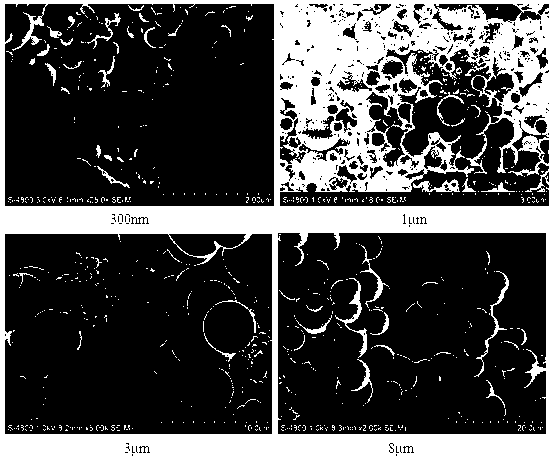

[0048] This example illustrates the synthesis method and synthesis results of carbon sphere materials.

[0049] 1) 300nm carbon spheres: configure 100mL of 0.5mol / L glucose solution, fully stir until the solution is clear, put it into a 150mL hydrothermal reaction kettle with a polytetrafluoroethylene lining, seal it, and conduct a hydrothermal reaction in an oven at 160°C for 5 hours, and the end After natural cooling, centrifuge at 15000r / min, the black carbon material was washed and centrifuged three times with purified water and ethanol respectively, and the final carbon material was obtained and dried in an oven at 80°C.

[0050] 2) 1μm carbon spheres: configure 100mL of 0.25mol / L starch solution, fully stir until the solution is clear, put it into a 150mL hydrothermal reaction kettle with a polytetrafluoroethylene lining, seal it, and conduct a hydrothermal reaction in an oven at 180°C for 5h, and the end After natural cooling, centrifuge at 15000r / min, the black carbon ...

Embodiment 2

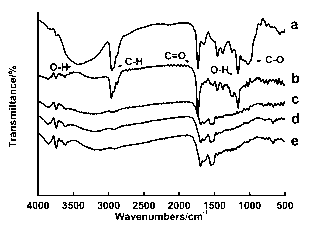

[0055] This example illustrates the superior structure of the synthetic carbon sphere material.

[0056] The carbon spheres of Example 1 were taken for infrared spectrum characterization. The result is as figure 2 As shown, the results show that carbon spheres are rich in carbon-oxygen bonds, as well as carbon-hydrogen bonds.

Embodiment 3

[0058] This example illustrates the specific steps for the synthesis of polyaspartic acid modified carbon sphere materials.

[0059] The 300nm carbon sphere obtained in Example 1 was taken, and the polyaspartic acid modified carbon sphere material was synthesized by the following steps.

[0060] Disperse 5 g of carbon spheres in 20 times the mass of deionized water, stir at high speed for 0.5 h to form a stable suspension, add 10 g of L-aspartic acid, 2 mL of 85% H 3 PO 4 Solution, 0.05g cross-linking agent N,N-methylenebisacrylamide, ultrasonically disperse at 200 watts for 1 hour, pass N 2 protection, then raised the temperature to 180°C for 1 hour, cooled to room temperature 25°C, washed with methanol and water three times each until neutral, and dried to obtain the intermediate product.

[0061] The obtained intermediate product was crushed, hydrolyzed for 0.5h under alkaline conditions, neutralized, and then the neutralized hydrolyzed solution was slowly poured into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com