Piezoelectric friction combined type micro-nano generator and prepared method thereof

A composite, generator technology, applied in the directions of triboelectric generators, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. The problem of poor charging capacity of capacitors, etc., achieves the effect of low cost, improved charging capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these examples, and the scope of the present invention is set forth in the claims.

[0041] Attached below figure 1 - Figure 4 illustrates the specific steps of the piezoelectric friction composite micro-nano generator and its preparation method provided by the present invention.

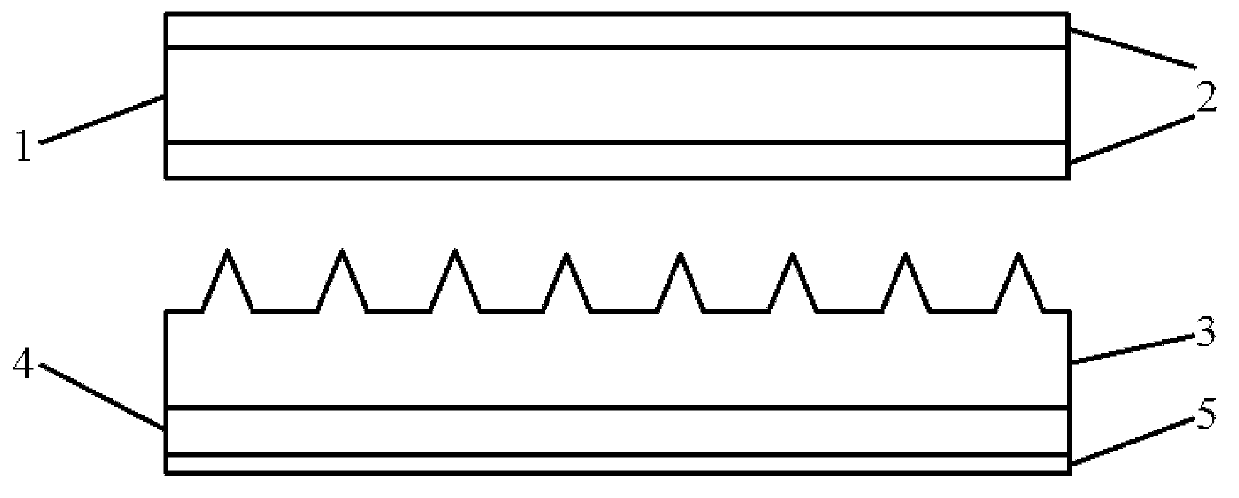

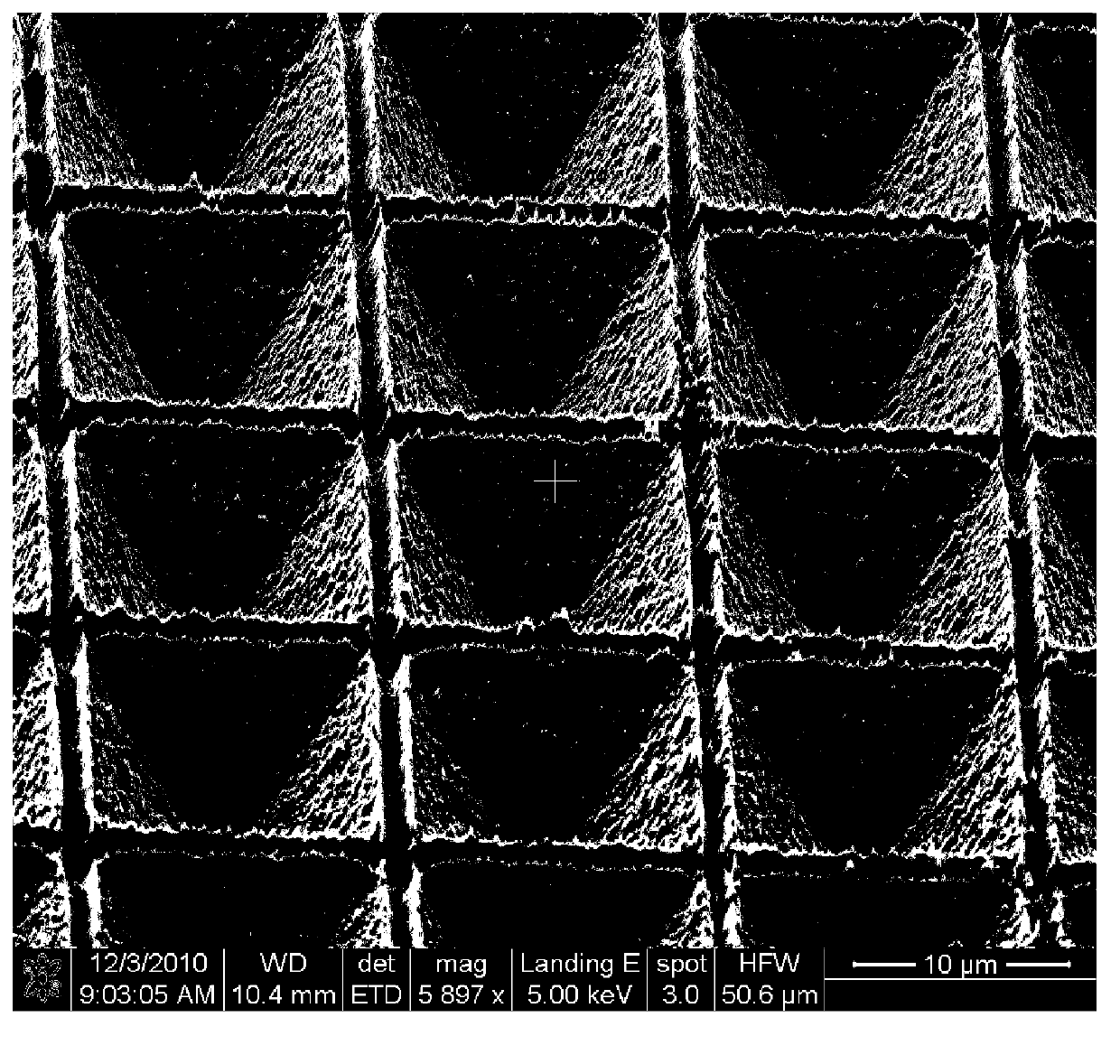

[0042] refer to figure 1 , figure 1 It is a structural schematic diagram of the piezoelectric friction compound generator of the present invention, and its structure includes: PVDF piezoelectric film 1, piezoelectric film electrode 2, PDMS film 3 with micro-nano composite structure, PET film 4, polymer material electrode 5. refer to figure 2 , figure 2 It is a scanning electron micrograph of the PVDF piezoelectric thin film of the present invention. refer to image 3 , image 3 It is a scanning electron micrograph of the mold with micro-nano composite s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Feature size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com