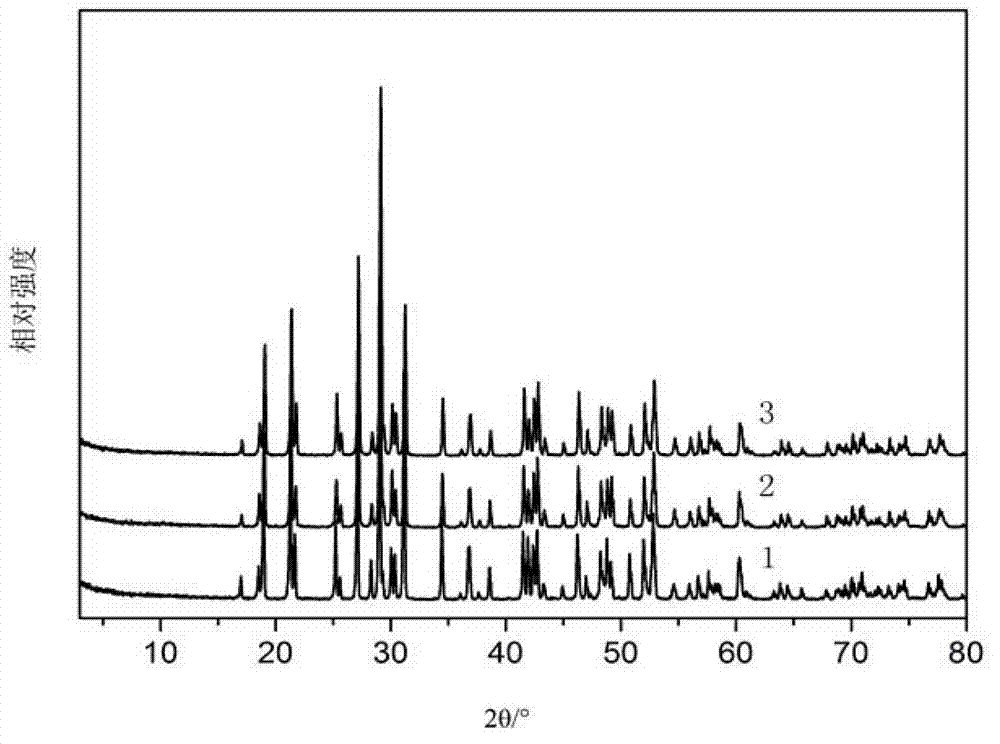

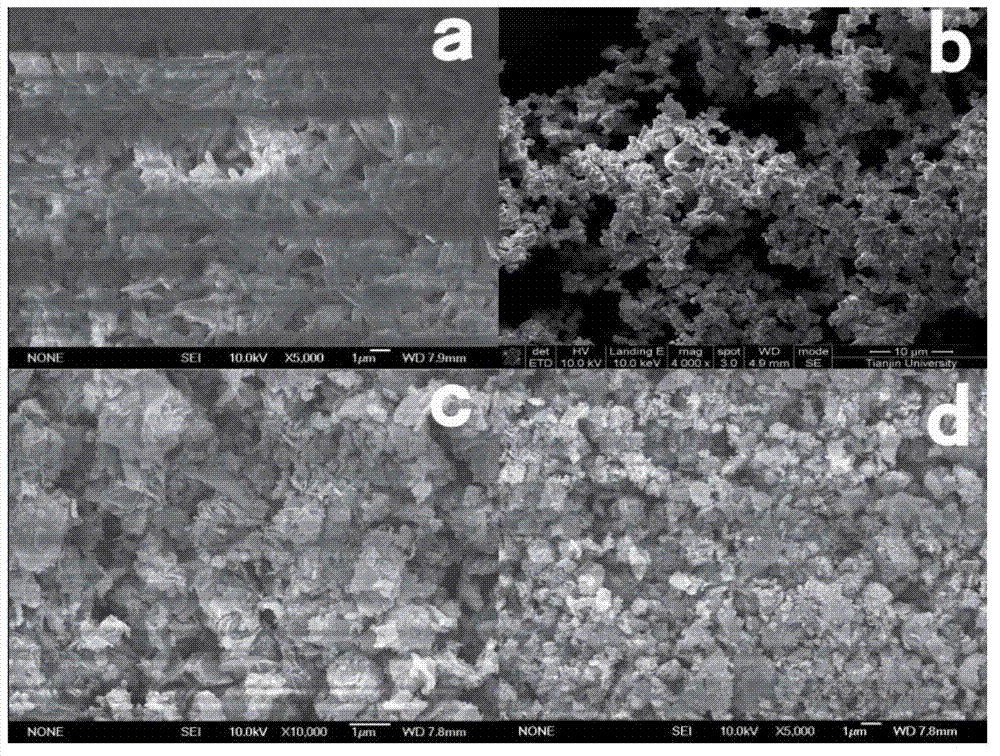

Preparation method of bismuth phosphate (BiPO4) photocatalysts differing in structure

A photocatalyst, bismuth phosphate technology, applied in chemical instruments and methods, physical/chemical process catalysts, phosphorus compounds, etc., can solve the problems of low light utilization efficiency, less research on preparation methods, and high electron-hole recombination efficiency. , to achieve the effect of easy identification, low cost and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A different structure bismuth phosphate (BiPO 4 ) The preparation method of the photocatalyst is prepared by a hydrothermal method, and the steps are as follows:

[0021] 1) Under magnetic stirring conditions, 0.002molBi(NO 3 ) 3 ·5H 2 O was dissolved in 15ml of absolute ethanol, stirred for 20min to obtain solution A;

[0022] 2) Add 0.002molNa 2 HPO 4 12H 2 0 was dissolved in 15ml of absolute ethanol, and stirred to obtain solution B;

[0023] 3) Add solution B dropwise to solution A under magnetic stirring, and continue magnetic stirring for 30 minutes after the dropwise addition to obtain a precursor solution;

[0024] 4) Transfer the above precursor solution to a stainless steel reactor lined with polytetrafluoroethylene, the filling volume of the precursor solution is 80%, the water heating temperature is 180°C, and the water heating time is 6 hours;

[0025] 5) After the reaction, cool to room temperature, wash repeatedly with deionized water and absolute...

Embodiment 2

[0027] A different structure bismuth phosphate (BiPO 4 ) The preparation method of the photocatalyst is prepared by a hydrothermal method, and the steps are as follows:

[0028] 1) Prepare 100ml of phosphoric acid solution with pH=1 as solvent;

[0029] 2) Under magnetic stirring conditions, 0.002molBi(NO 3 ) 3 ·5H 2 O was dissolved in 15ml of prepared phosphoric acid solution, stirred for 20min to obtain solution A;

[0030] 3) Add 0.002molNa 2 HPO 4 12H 2 0 was dissolved in 15ml of prepared phosphoric acid solution, and stirred to obtain solution B;

[0031] 4) Under magnetic stirring, add solution B dropwise to solution A, and continue magnetic stirring for 30 minutes after the dropwise addition to obtain a precursor solution;

[0032] 5) Transfer the above precursor solution to a stainless steel reactor lined with polytetrafluoroethylene, the filling volume of the precursor solution is 80%, the water heating temperature is 180°C, and the water heating time is 24 ho...

Embodiment 3

[0035] A different structure bismuth phosphate (BiPO 4 ) The preparation method of the photocatalyst is prepared by a hydrothermal method, and the steps are as follows:

[0036] 1) Under magnetic stirring conditions, 0.002molBi(NO 3 ) 3 ·5H 2 O was dissolved in 15ml polyethylene glycol and stirred for 20min to obtain solution A;

[0037] 2) Add 0.002molNa 2 HPO 4 12H 2 0 was dissolved in 15ml polyethylene glycol, and stirred to obtain solution B;

[0038] 3) Add solution B dropwise to solution A under magnetic stirring, and continue magnetic stirring for 30 minutes after the dropwise addition to obtain a precursor solution;

[0039] 4) Transfer the above precursor solution to a stainless steel reactor lined with polytetrafluoroethylene, the filling volume of the precursor solution is 80%, the water heating temperature is 180°C, and the water heating time is 6 hours;

[0040] 5) After the reaction, cool down to room temperature, wash repeatedly with deionized water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com