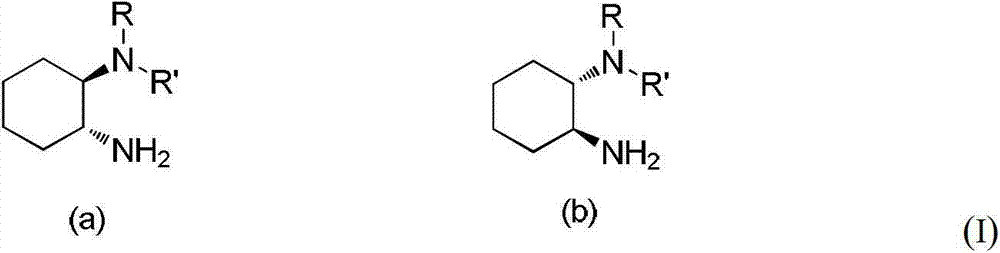

Chirality N, N-dialkyl-1, 2-diaminocyclohexane catalyst as well as preparation method and application thereof

A cyclohexanediamine catalyst and cyclohexanediamine technology are used in the preparation of amino compounds, the preparation of carbon-based compounds, chemical instruments and methods, etc., to achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

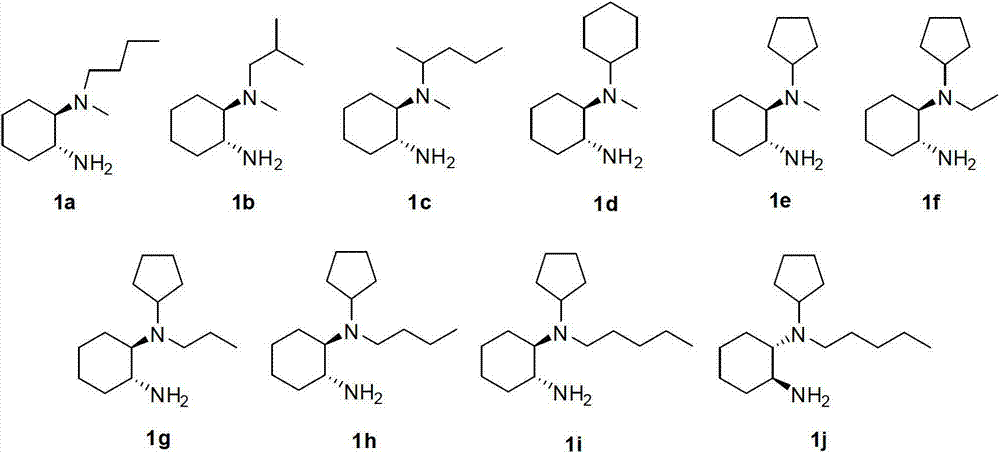

[0035] Example 1. (1R,2R)-N 1 -Butyl-N 1 - Preparation of methyl-1,2-cyclohexanediamine dihydrochloride (1a·2HCl).

[0036] (1R,2R)-N 1 -Butyl-N 1 -The structural formula of methyl-1,2-cyclohexanediamine dihydrochloride (1a 2HCl) is as follows:

[0037]

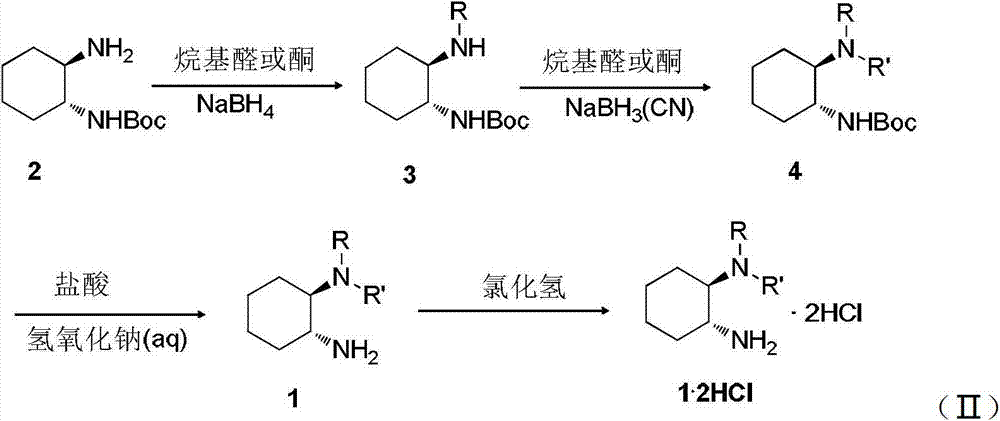

[0038] Concrete preparation steps are as follows:

[0039] Add 10mmol of (1R,2R)-1,2-cyclohexanediamine protected by mono-tert-butoxycarbonyl and 50mmol of n-butyraldehyde into 50mL of methanol, and react at 0~20°C for 4~5 hours. The reaction solution was cooled in an ice bath, and then 30 mmol NaBH 4 Add in batches, continue to react for 0.5 hours, and then heat to 25°C for 3 hours to obtain intermediate 3a (the product does not need to be isolated). Add 20mmolNaBH to the reaction solution 3 (CN), 2.4mL formaldehyde solution with mass percent concentration of 37%, reacted at 30°C for 5 hours. The solvent was removed under reduced pressure, 40 mL of 1 mol / L NaOH aqueous solution was added, and 50 mL of ethyl acetate ...

Embodiment 2

[0042] Example 2. (1R,2R)-N 1 -Isobutyl-N 1 - Preparation of methyl-1,2-cyclohexanediamine dihydrochloride (1b·2HCl).

[0043] (1R,2R)-N 1 -Isobutyl-N 1 -The structural formula of methyl-1,2-cyclohexanediamine dihydrochloride (1b 2HCl) is as follows:

[0044]

[0045] Concrete preparation steps are as follows:

[0046] Add 10mmol of (1R,2R)-1,2-cyclohexanediamine protected by mono-tert-butoxycarbonyl and 50mmol of isobutyraldehyde into 50mL of methanol solution, and react at 20~40°C for 3~4 hours. The reaction solution was cooled in an ice bath, and then 30 mmol NaBH 4 Add in batches, continue to react for 1.5 hours, and then heat to 40°C for 2 hours to obtain intermediate 3b (the product does not need to be isolated). Add 20mmolNaBH to the reaction solution 3 (CN), 2.4mL formaldehyde solution with mass percent concentration of 37%, reacted at 25°C for 8 hours. The solvent was removed under reduced pressure, 40 mL of 1 mol / L NaOH aqueous solution was added, and 50 m...

Embodiment 3

[0049] Example 3. (1R,2R)-N 1 -(2-Pentyl)-N 1 - Preparation of methyl-1,2-cyclohexanediamine dihydrochloride (1c·2HCl).

[0050] (1R,2R)-N 1 -(2-Pentyl)-N 1 -The structural formula of methyl-1,2-cyclohexanediamine dihydrochloride (1c 2HCl) is as follows:

[0051]

[0052] Concrete preparation steps are as follows:

[0053] Add 10mmol of (1R,2R)-1,2-cyclohexanediamine protected by mono-tert-butoxycarbonyl and 50mmol of 2-pentanone into 50mL of methanol solution, and react at 40~60°C for 2~3 hours. The reaction solution was cooled in an ice bath, and then 30 mmol NaBH 4 Added in batches, continued to react for 2 hours, and then heated to 60°C for 0.5 hours to obtain intermediate 3c (the product does not need to be isolated). Add 20mmolNaBH to the reaction solution 3 (CN), 2.4mL formaldehyde solution with mass percent concentration of 37%, reacted at 20°C for 12 hours. The solvent was removed under reduced pressure, 40 mL of 1 mol / L NaOH aqueous solution was added, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com