Method for preparing flammulina velutipes polysaccharides and protein efficiently synchronously

A technology of Flammulina velutipes polysaccharide and Flammulina velutipes, which is applied in the fields of peptide preparation, chemical instruments and methods, organic chemistry, etc., can solve the problems of inability to prepare protein components at the same time, waste, low extraction rate, etc., achieves less explosion, realizes regeneration and recovery , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

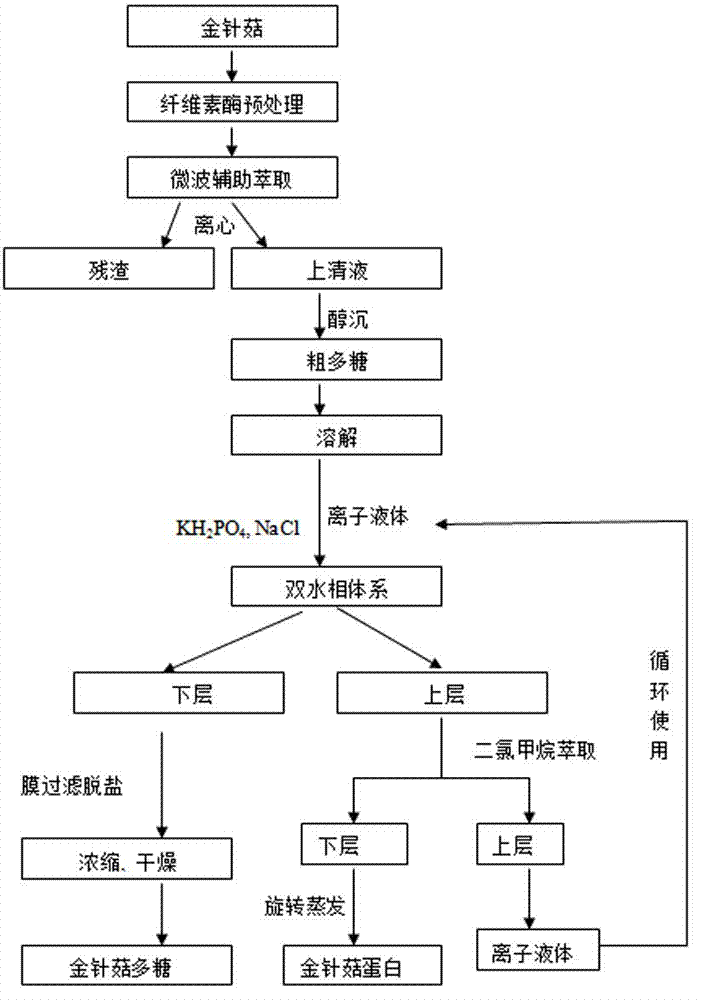

Image

Examples

Embodiment 1

[0033] Embodiment 1 (method 1 for simultaneously and efficiently preparing polysaccharide and protein from Flammulina velutipes)

[0034] (1) Raw material pretreatment: After crushing 10g of dried Flammulina velutipes fruiting bodies, mix it with distilled water at a weight ratio of 1:30 to form a mixture, and set aside;

[0035] (2) Enzymolysis treatment: Add 0.05% of cellulase by weight to the mixture, adjust the pH value to 4, and place it on a shaker at 45°C for 30 minutes;

[0036] (3) Microwave-assisted extraction: Step (2) Microwave treatment of the enzymatic hydrolyzate (80H Z , 500W) after 5 minutes, centrifuge at 6000 rpm for 10 minutes to obtain supernatant and sediment;

[0037] (4) Alcohol-precipitation of polysaccharides. Concentrate the supernatant of step (3) under reduced pressure with a rotary evaporator to one-fifth of the original volume. Centrifuge for 10 minutes, freeze and dry to obtain 0.92g of Flammulina velutipes crude polysaccharide;

[0038] (5...

Embodiment 2

[0042] Embodiment 2 (from Flammulina velutipes simultaneously and efficiently prepare the method two of polysaccharide and albumen)

[0043](1) Raw material pretreatment: After crushing 10 g of dried Flammulina velutipes fruiting bodies, mix it with distilled water at a weight ratio of 1:40 to form a mixture, and set aside;

[0044] (2) Enzymolysis treatment: Add 0.1% cellulase by weight of the mixture to the mixture, adjust the pH value to 4.5, place it on a shaker at 48°C for 50 minutes;

[0045] (3) Microwave-assisted extraction: Step (2) Microwave treatment of the enzymatic hydrolyzate (80H Z , 800W) after 10 minutes, centrifuge at 6000 rpm for 10 minutes to obtain supernatant and sediment;

[0046] (4) Alcohol-precipitation of polysaccharides. Concentrate the supernatant of step (3) under reduced pressure with a rotary evaporator to one-fifth of the original volume. Centrifuge for 10 minutes, freeze and dry to obtain 1.04g of Flammulina velutipes crude polysaccharide;...

Embodiment 3

[0051] Embodiment 3 (from Flammulina velutipes the method three of preparing polysaccharide and albumen simultaneously)

[0052] (1) Raw material pretreatment: After crushing 10g of dried Flammulina velutipes fruiting bodies, mix it with distilled water at a weight ratio of 1:45 to form a mixture, and set aside;

[0053] (2) Enzymolysis treatment: Add 0.15% of the weight of cellulase to the mixture, adjust the pH value to 5.5, and place it on a shaker at 50°C for 70 minutes;

[0054] (3) Microwave-assisted extraction: Step (2) Microwave treatment of the enzymatic hydrolyzate (50H Z , 500W) after 15 minutes, centrifuge at 6000 rpm for 10 minutes to obtain supernatant and sediment;

[0055] (4) Alcohol-precipitation of polysaccharides. Concentrate the supernatant of step (3) under reduced pressure with a rotary evaporator to one-fifth of the original volume. Centrifuge for 10 minutes, freeze and dry to obtain 1.11 g of Flammulina velutipes crude polysaccharide;

[0056] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com