High-performance epoxy resin and preparation method thereof

An epoxy resin, high-performance technology, applied in the field of epoxy resin, can solve the problems of complex POSS improvement method and insufficient performance improvement, and achieve resistance to damage by external force, improvement of limiting oxygen index, good heat resistance and flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

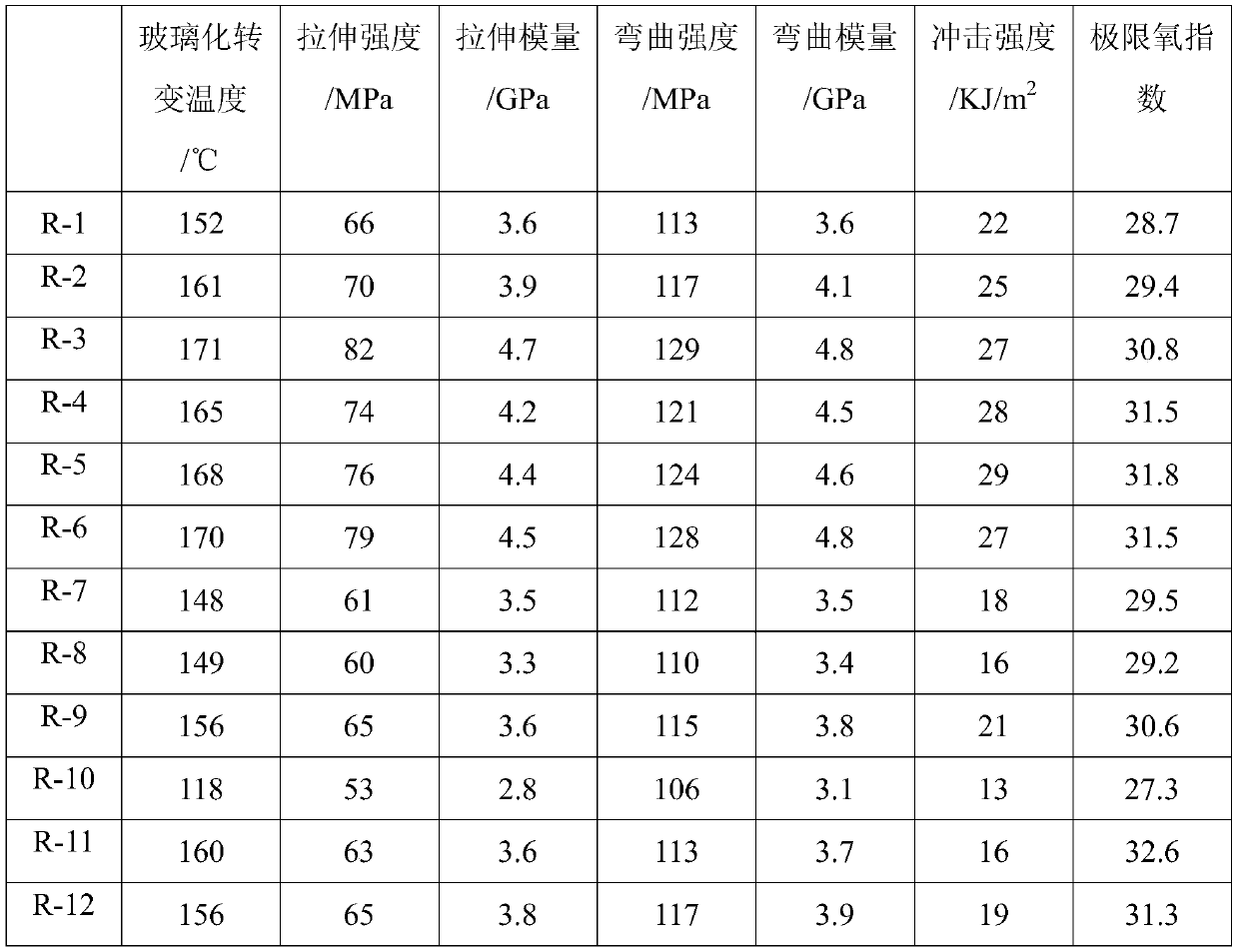

Examples

Embodiment 1

[0027] The epoxy resin is composed of the following components: 50 parts of bisphenol A type epoxy resin, 2 parts of benzyl glycidyl ether, 1 part of octagamma-(2,3-glycidoxy) propyl POSS, 3 parts Polyaryl phosphate, 30 parts of active silica powder, 0.6 part of wetting and dispersing agent and 0.6 part of defoamer;

[0028] The curing agent consists of the following components: 3 parts of diaminopropylhexapropyl POSS and 6 parts of diethylenetriamine;

[0029] Bisphenol A type epoxy resin, benzyl glycidyl ether and eight γ-(2,3-epoxypropoxy) propyl POSS are mixed and stirred evenly, and active silica powder is added in three times, stirred and mixed evenly, and polyaromatic base phosphate, wetting and dispersing agent and defoamer, stir and mix evenly, add curing agent composed of diaminopropylhexapropyl POSS and diethylenetriamine, stir evenly, vacuum defoaming, pour into the mold, heat up Curing at 60°C for 20 minutes, raising the temperature to 100°C and curing for 30 min...

Embodiment 2

[0031] The epoxy resin is composed of the following components: 60 parts of bisphenol F type epoxy resin, 3.5 parts of butyl glycidyl ether, 3 parts of tetraepoxyethyl tetravinyl POSS, 4 parts of tert-butylphenyl diphenyl phosphate , 45 parts of wollastonite, 0.9 part of wetting and dispersing agent and 0.8 part of defoamer;

[0032] The curing agent is composed of the following components: 7 parts of diaminopropylhexaphenyl POSS and 10 parts of m-phenylenediamine;

[0033] Bisphenol F type epoxy resin, butyl glycidyl ether and tetraepoxyethyl tetravinyl POSS are mixed and stirred evenly, wollastonite is added in 4 times, stirred and mixed evenly, tert-butylphenyl diphenyl phosphate, moistening Wet dispersant and defoamer, stir and mix evenly, add curing agent composed of diaminopropylhexaphenyl POSS and m-phenylenediamine, stir evenly, vacuum defoaming, pour into the mold, heat up to 50°C and cure for 20 Minutes, the temperature was raised to 90°C and cured for 30 minutes, a...

Embodiment 3

[0035] The epoxy resin is composed of the following components: 80 parts of bisphenol A type epoxy resin, 5 parts of dodecyl glycidyl ether, 5 parts of eight β-(3,4-epoxycyclohexyl) ethyl POSS, 5 parts 1 part of aluminum hydroxide, 60 parts of active silica powder and 1 part of wetting and dispersing agent;

[0036] The curing agent is composed of the following components: 12 parts of aminopropylheptaphenyl POSS and 20 parts of diaminodiphenylmethane;

[0037] Bisphenol A type epoxy resin, dodecyl glycidyl ether and eight β-(3,4-epoxycyclohexyl) ethyl POSS are mixed and stirred evenly, and active silica powder is added in 4 times, stirred and mixed evenly, and hydrogen Alumina and wetting and dispersing agent, stir and mix evenly, add curing agent composed of aminopropyl heptaphenyl POSS and diaminopropyl diphenylmethane, stir evenly, vacuum defoaming, pour into the mold, heat up to 60 Cure for 2 hours, raise the temperature to 150°C and cure for 2 hours, then lower the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com