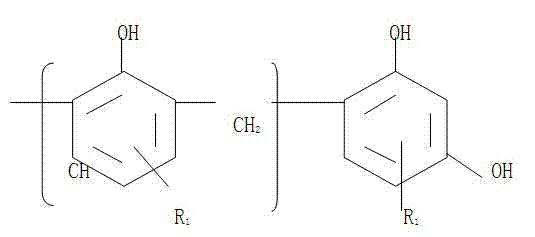

Resorcinol aldehyde resin formed by modification of olefin and aromatic hydrocarbon and production process thereof

A technology of resorcinol aldehyde and resorcinol, which is applied in the field of resorcinol aldehyde resin and its production process, can solve the problems of potential safety hazards, inconvenient use, and high viscosity of rubber materials, so as to improve product performance, solve Blooming problem, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 250g of resorcinol to a 1000ml reaction bottle, heat up to complete melting, then add 6g of sulfuric acid under stirring, start to add 55g of styrene dropwise when the temperature rises to 120°C, after about 30 minutes, keep the temperature for 30 Minutes, lower the temperature, then start to drop 110g of formaldehyde solution with a mass concentration of 36.5-37% at 105°C, and drop it for about 1 hour, after that, reflux reaction at 95-105°C for 30 minutes, then heat up and dehydrate, and the water will be completely removed Finally, add 60g of diisobutene dropwise, and react with 125-145°C for 1.5 hours, then neutralize with 20% NaOH aqueous solution, distill and dehydrate at 170°C for 120 minutes to remove small molecules, when the product softening point is 95°C When, free phenol 0.65%.

Embodiment 2

[0022] Into the 1000ml reaction bottle, add resorcinol 250g, water 150g is warmed up to dissolve completely, add H under stirring 2 SO 4 6g, when the temperature rises to 95°C, start to add 115g of formaldehyde solution with a mass concentration of 36.5-37%. Add 110g of a mixture of styrene and diisobutylene (50% by weight each) dropwise, and add dropwise at a temperature of 120-130°C, and react at 125-145°C for 1.5 hours after dropping, add 20% NaOH aqueous solution to neutralize, Distill at 180°C for 120 minutes to remove all water and small molecules. When the softening point of the product is 100°C, the free phenol is 0.6%.

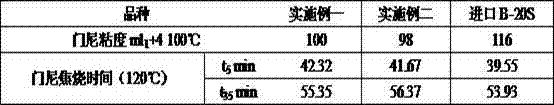

[0023] Comparison of the application performance of the sample synthesized in the example and the imported B-20S (pure styrene modified) sample in the rubber compound:

[0024] Table 1 Comparison of physical properties of rubber compounds

[0025]

[0026] Table 2 Physical properties of vulcanizates

[0027] Variety Embodiment one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com