Functional paint and preparation method thereof

A functional coating and coating technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as affecting the smoothness of the paint film and reducing the gloss of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0279] An anticorrosion coating for knives, which comprises a basic coating and a silicone resin, the volume ratio of the basic coating and the silicone resin is 1:0.5.

[0280] The invention discloses a preparation method of an anti-corrosion coating for knives. After mixing a basic coating and a silicone resin, the anti-corrosion coating for knives is obtained.

[0281] The volume percentage of the basic coating is as follows: 5% of the pH regulator, 0.001% of the functional catalyst, and 94.999% of the siloxane composition;

[0282] The preparation method of described basic paint, its concrete steps are:

[0283] 1. Control the temperature in the reactor at 40°C, and add the siloxane composition according to the amount while stirring. The stirring rate is 300r / min, and the stirring is slow for about 5 minutes until the mixture is uniform;

[0284] Second, the H in the pH regulator 2 Mix O and the mixed acid evenly in another clean container, and slowly add it dropwise to ...

Embodiment 2-5

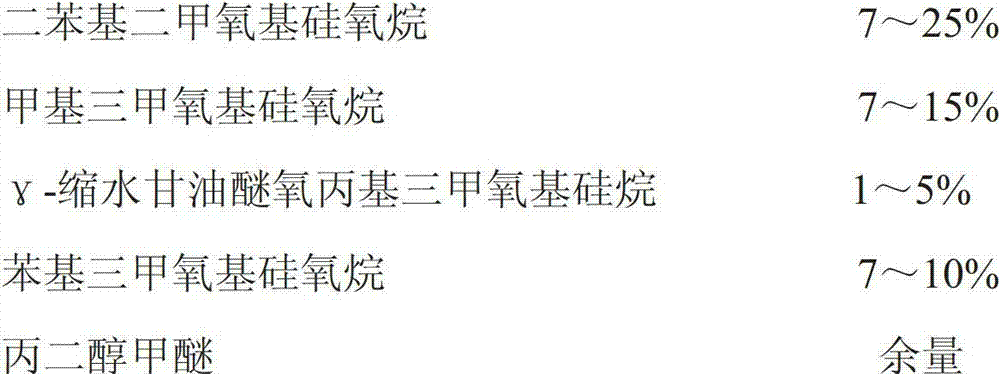

[0299] An anti-corrosion coating for knives, the specific preparation method is shown in technical route 1, wherein the ratio of raw materials is shown in Table 2.

[0300] Table 1 is a raw material ratio of an anti-corrosion coating for knives

[0301]

Embodiment 6-10

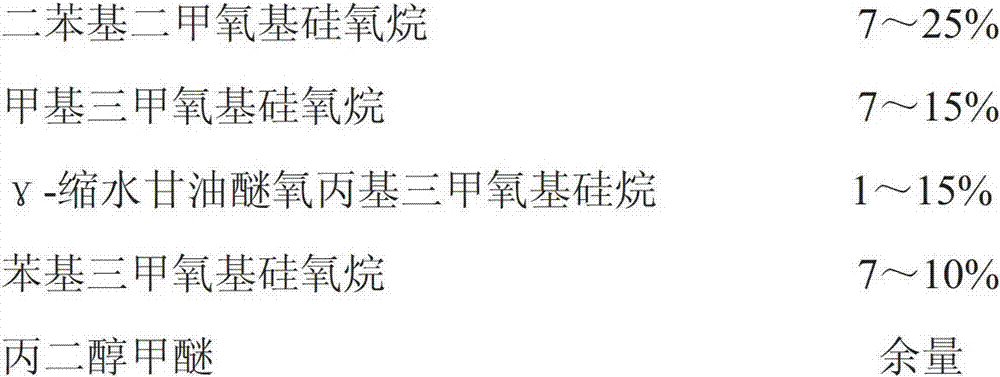

[0303] An anti-corrosion coating for cast iron cooktops, the specific preparation method is shown in technical route 2, wherein the ratio of raw materials is shown in Table 2.

[0304] Table 2 is a kind of raw material proportioning situation for the anticorrosion coating of cast iron stove head

[0305]

[0306]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com