New electrode modification method

A technology of electrode modification and conductive agent, which is applied to battery electrodes, circuits, electrical components, etc., and can solve the problems of low capacity and energy of lithium-ion batteries and the inability to meet the requirements of large electrical appliances for electric vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

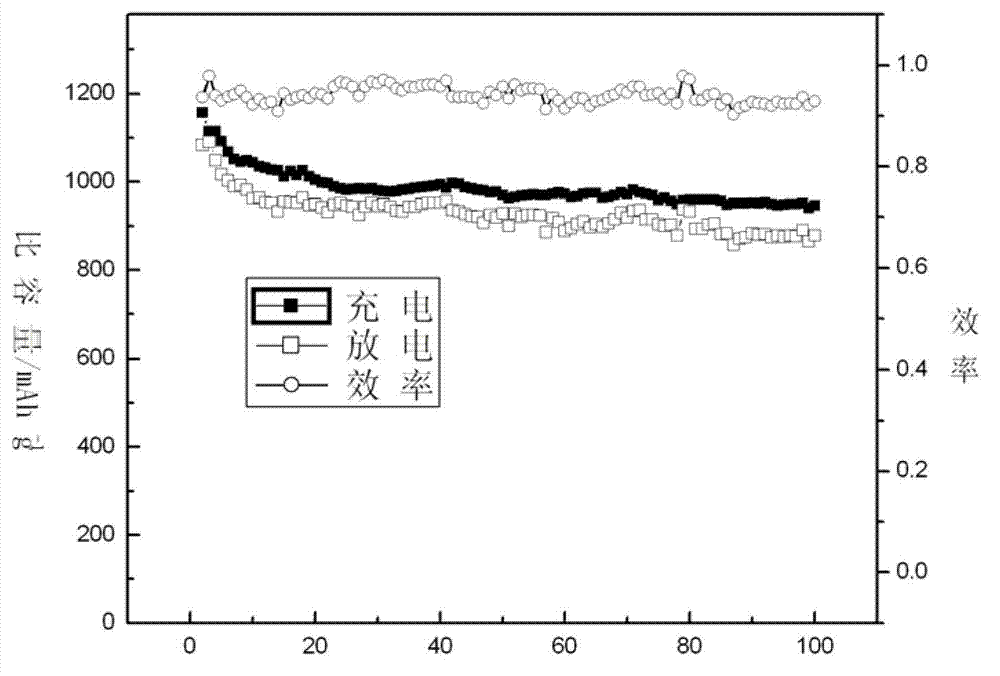

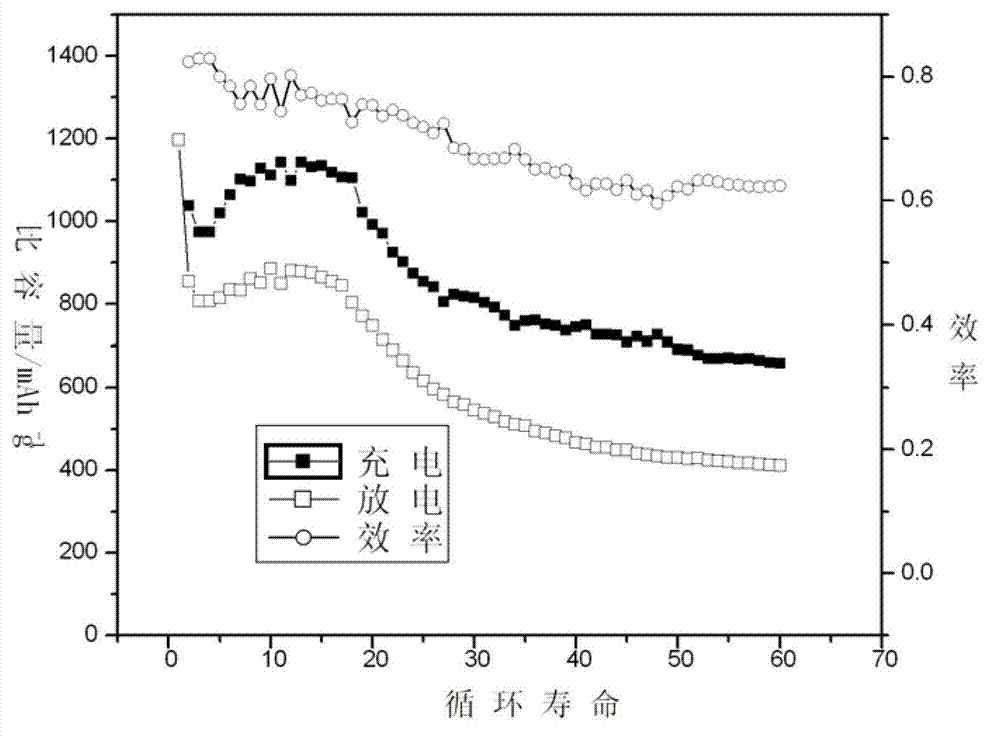

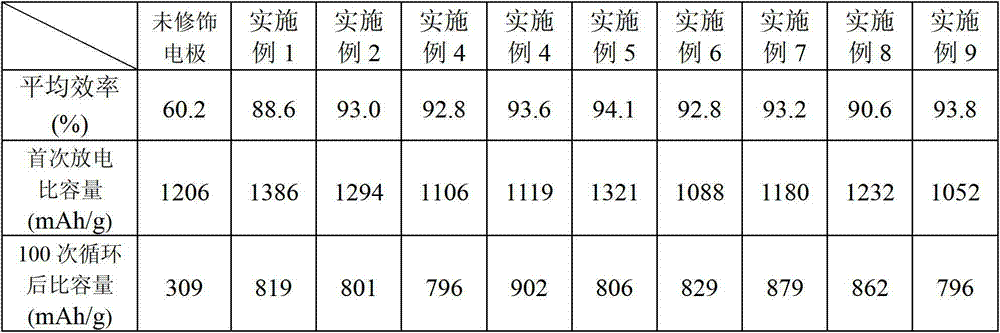

Examples

Embodiment 1

[0018] (1) Add the sublimated sulfur and super-P into the grinding tank at a ratio of 7:2, add 25 ml of ethanol, mill in a ball mill with a rotating speed of 300r / min for 9 hours, take it out, and put it in a blast drying oven at 50°C Dried to make a sulfur / super-P composite material.

[0019] (2) Mix the sulfur / super-P composite material with acetylene black and PVDF in a weight ratio of 7:2:1 by wet method, apply it on aluminum foil, and dry it in a blast drying oven at 50°C to prepare into electrodes.

[0020] (3) The DOW film solution with a mass fraction of 1% was evenly coated on the surface of the electrode, and then dried at room temperature to form a film to make a modified electrode.

Embodiment 2

[0022] (1) Add the sublimated sulfur and acetylene black into the grinding tank at a ratio of 7:2, add an appropriate amount of 25 ml of ethanol, mill in a ball mill with a rotation speed of 300r / min for 9 hours, take it out, and place it in a blast drying oven at 50°C Dry to make sulfur / acetylene black composite material.

[0023] (2) Mix the sulfur / acetylene black composite material, acetylene black, and PVDF in a weight ratio of 7:2:1 by a wet method, apply it on an aluminum foil, and dry it in a blast drying oven at 50°C to obtain electrode.

[0024] (3) The DOW film solution with a mass fraction of 2% was evenly coated on the surface of the electrode, and then dried at room temperature to form a film to make a modified electrode.

Embodiment 3

[0026] (1) Add the sublimated sulfur and BP2000 into the grinding tank at a ratio of 8:2, add an appropriate amount of 25 ml of ethanol (the specific value should be used), ball mill in a ball mill with a rotating speed of 300r / min for 9 hours, take it out, and dry it in the air Dry it in a box at 50°C to make a sulfur / BP2000 composite material.

[0027] (2) Then, the sulfur / BP2000 composite material, acetylene black, and PVDF were mixed uniformly by wet method in a weight ratio of 7:2:1, coated on aluminum foil, and dried at 50°C in a blast drying oven to obtain electrode.

[0028] (3) The Aciplex membrane solution with a mass fraction of 5% was evenly coated on the surface of the electrode, and then dried at room temperature to form a film to make a modified electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com