Lithium ion battery and production method thereof

A lithium-ion battery and battery technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of high-temperature cycle performance and poor cycle performance at large rates, and achieve improved contact adhesion and increased rate. performance, the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

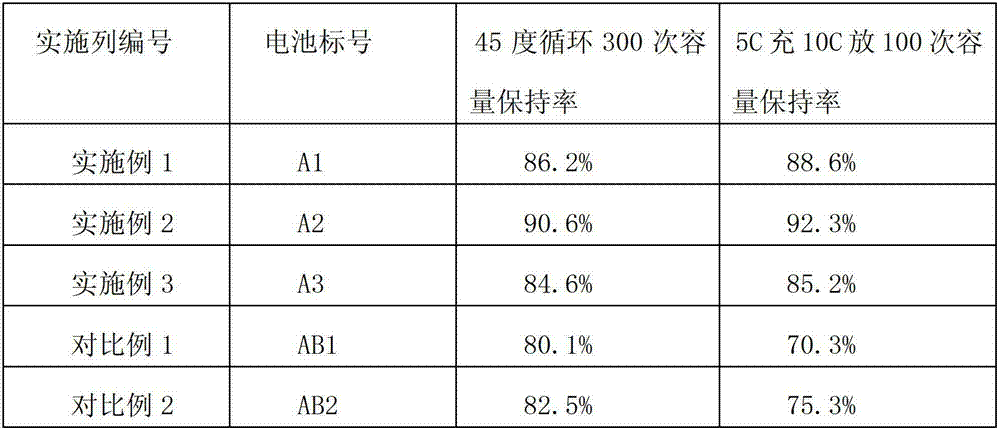

Examples

preparation example Construction

[0030] Preparation of the positive electrode sheet: 80-115 parts of the positive active ingredient, 2-4 parts of the binder, and 2-5 parts of the positive electrode conductive agent are added to 48-130 parts of the solvent in a mass fraction ratio, and stirred to form Uniform positive electrode active material slurry; when the viscosity of the slurry is in the range of 5000-15000mPa.S, the positive electrode active material slurry is evenly coated on the graphite foil current collector, and the positive electrode active material slurry coated The positive electrode current collector of the raw material is dried, rolled and cut to form the positive electrode sheet; the active component of the positive electrode is lithium cobaltate LiCoO 2 , lithium iron phosphate LiFePO 4 , nickel cobalt lithium manganese oxide LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 and lithium manganese oxide LiMn 2 o 4 One or more mixtures; the binder is polyvinylidene fluoride (PVDF), and the positive electrode c...

Embodiment 1

[0038] A lithium-ion battery, which includes a casing, an electrolyte, a separator, a positive electrode sheet and a negative electrode sheet, wherein a separator is sandwiched between the positive electrode sheet and the negative electrode sheet, and the positive electrode sheet, the negative electrode sheet and the separator are all stacked on the In the casing, electrolyte is filled between the positive electrode sheet, the negative electrode sheet and the separator, wherein the positive electrode sheet is composed of a graphite foil current collector coated with a positive electrode active material slurry; the negative electrode sheet is a metal foil collector coated with a negative electrode active material. Material paste composition.

[0039] The positive electrode active material slurry is adhered to the graphite foil current collector through the binder, and the negative electrode active material slurry is adhered to the copper foil current collector through the binder...

Embodiment 2

[0046] A method of making a lithium-ion battery, which includes the preparation of a positive electrode sheet, the preparation of a negative electrode sheet and the assembly of the battery,

[0047] Preparation of the positive electrode sheet: 93 parts of positive electrode active ingredient LiFePO 4 , 4 parts of binder polyvinylidene fluoride (PVDF), 3 parts of carbon nanotubes, added to 120 parts of N-methylpyrrolidone, and then stirred in a vacuum mixer to form a uniform positive electrode active material slurry, the viscosity of the slurry The test is 12000mPa.S, and then the slurry is uniformly coated on a graphite foil current collector with a width of 300 mm and a thickness of 55 microns by a coating machine, wherein the coating speed of the coating machine is set to 1.5 m / min. The temperature and drying range of the cloth is 100-125 degrees, and then rolled and cut to obtain a positive electrode sheet with a width of 64 mm and a length of 255 mm;

[0048] Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com