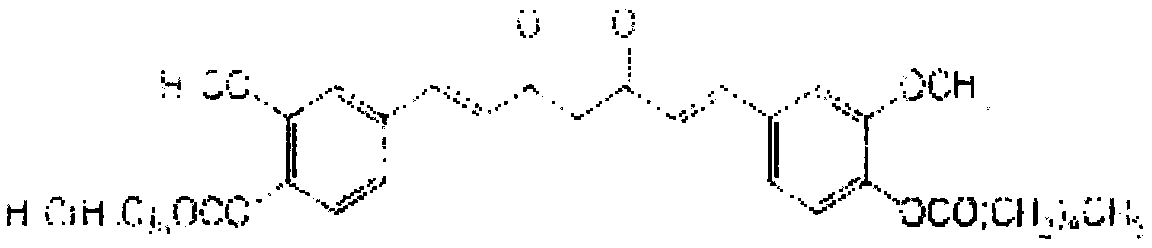

Curcumin dicaprate suspension injection and preparation method and application thereof

A technology of dicaprate and injection, which is applied in the field of medicine, can solve the problems of low solubility, difficulty in injection, and low solubility of curcumin dicaprate, and achieve the effects of simple prescription, great practical value, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 curcumin dicaprate nanosuspension

[0022] The planetary ball mill of the present invention uses water for injection as the solvent for wet grinding, weighs 1.00 g of CurDD during grinding, adds 25 g of balls, adds 1 ml of aqueous solution containing 50 mg of poloxamer 401, and grinds for 1 hour at a rotating speed of 650 rpm in a parallel planetary ball mill Grind, add water after completion, transfer to clean vials several times, seal with tin foil, store at -80°C for 24 hours, and then put it in a freeze dryer. Program freeze-drying: pre-freeze at -45°C for 6 hours; Operate at -30°C for 18 hours, at -20°C for 5 hours, and at 0°C for 4 hours; perform secondary drying at 20°C for 4 hours to obtain a lyophilized powder. The obtained lyophilized powder is a yellow powdery solid with a good appearance, no collapse or shrinkage on the surface, and some small cracks. Accurately weigh 500 mg of freeze-dried nano-suspension particles, disperse...

Embodiment 2

[0024] Embodiment 2 curcumin dicaprate nanoparticles particle size distribution

[0025] Firstly, the optical path is calibrated before the experiment (for the light, the detection pool of the instrument is water), so that the background has no large interference peaks, and the laser intensity is detected (greater than 70). The grinding particles of the ball mill are evenly dispersed in the dispersant, and the particles are dispersed with each other by ultrasonic waves, and then added dropwise into the particle size distribution instrument that is ready to be measured until the shading degree reaches 5-10. After mixing and stirring for a period of time, press the Start key to start the instrument to measure the particle size distribution. The measurement principle is that the particles pass through the laser beam at a certain flow rate. Different particle sizes have different diffraction angles. The diffracted light is collected by a detector and the received signal is conve...

Embodiment 3

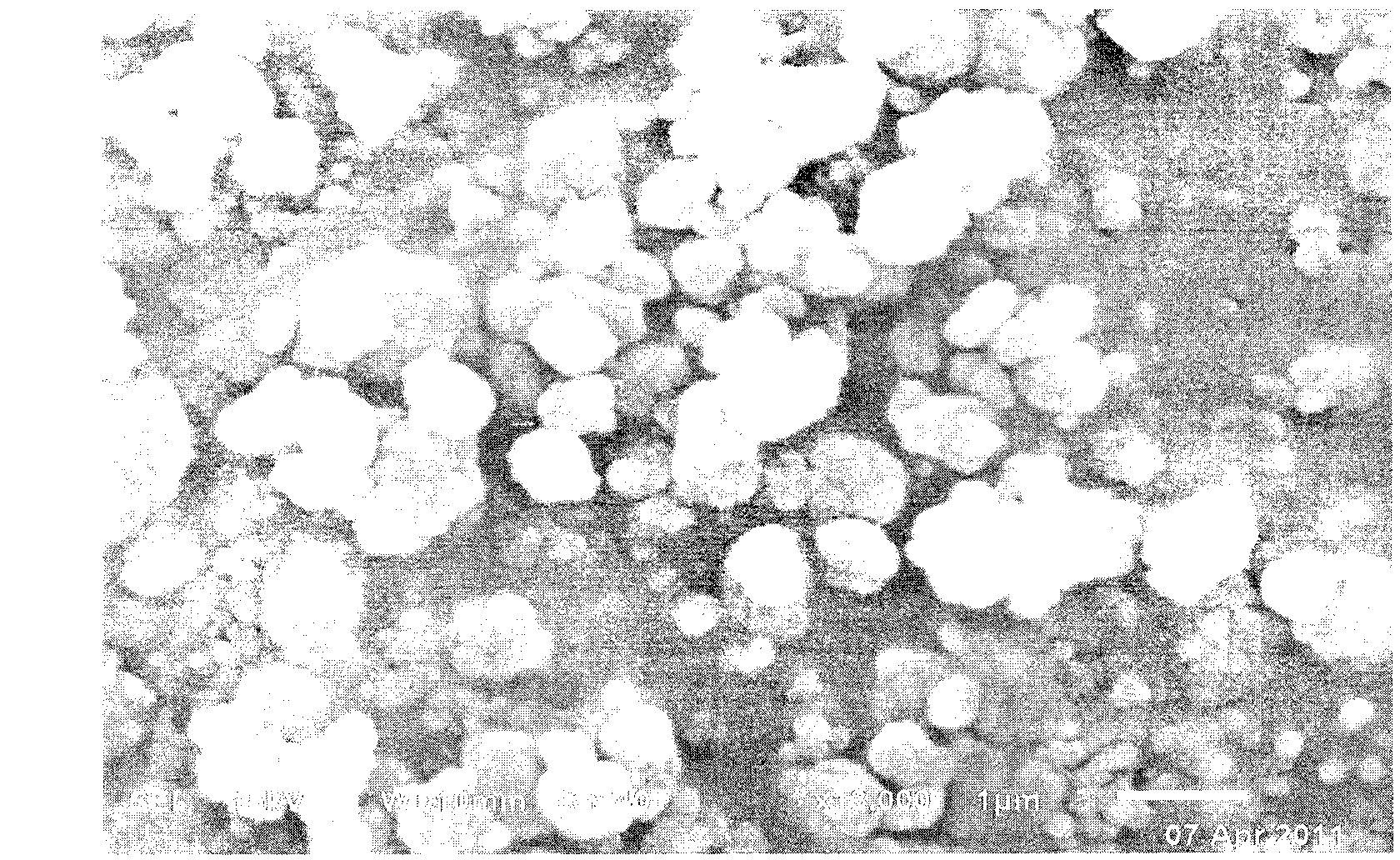

[0026] Embodiment 3 Curcumin Dicaprate Nanoparticle Morphological Observation

[0027] The particle morphology and particle size distribution observation of the curcumin dicaprate nano freeze-dried powder prepared in Experimental Example 1 was carried out with a scanning electron microscope. Particles were immobilized on metal sample pans and sprayed with gold (3nm). Depend on figure 2 It can be seen that the freeze-dried powder nanoparticles are spherical, and the particle size range is concentrated between 300-700nm, which is consistent with the particle size distribution measurement results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com