Preparation method of graphene-modified capillary-column chromatography

A technology of capillary electrochromatography and capillary column, which is applied in the field of capillary electrochromatography, can solve the problems of complicated preparation process and short service life, and achieves the effects of easy availability of raw materials, long service life and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a graphene-modified capillary electrochromatographic column, the specific steps comprising the following steps:

[0034] (1) Pretreatment of capillary;

[0035] Rinse the capillary with deionized water for 10 minutes, then rinse the capillary with NaOH solution for 4 hours, and then rinse with deionized water for 10 minutes;

[0036] (2) polyelectrolyte modified capillary inner wall;

[0037] Select a cationic electrolyte, prepare 8% (w / v) polydiallyldimethylammonium chloride (PDDA) solution, and add 0.5M salt solution to it to form a cationic polyelectrolyte coating solution;

[0038] Inject the above prepared liquid into the pretreated capillary column within 5 minutes, and then rinse the capillary with deionized water for 5 minutes to form a cationic capillary column;

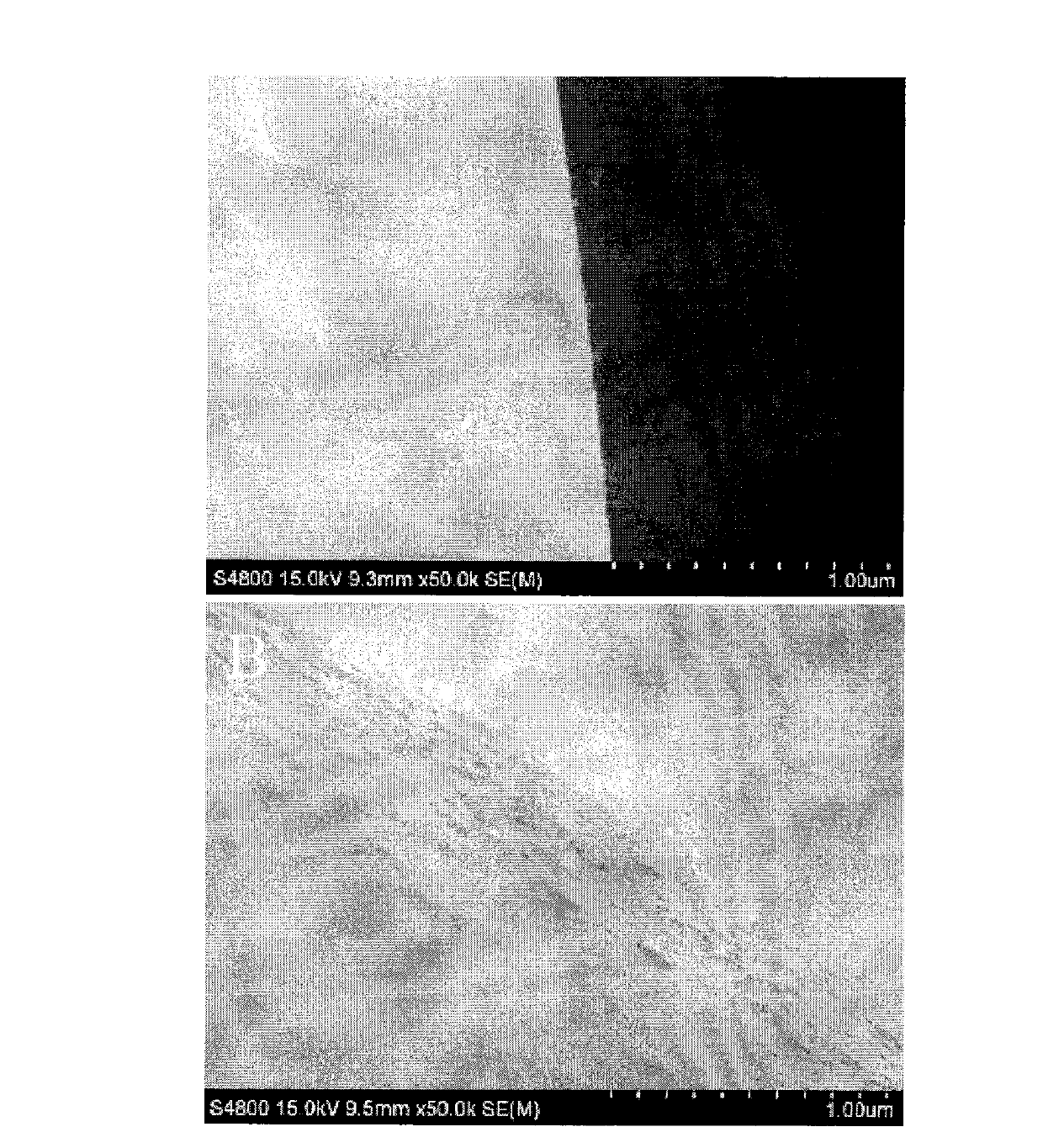

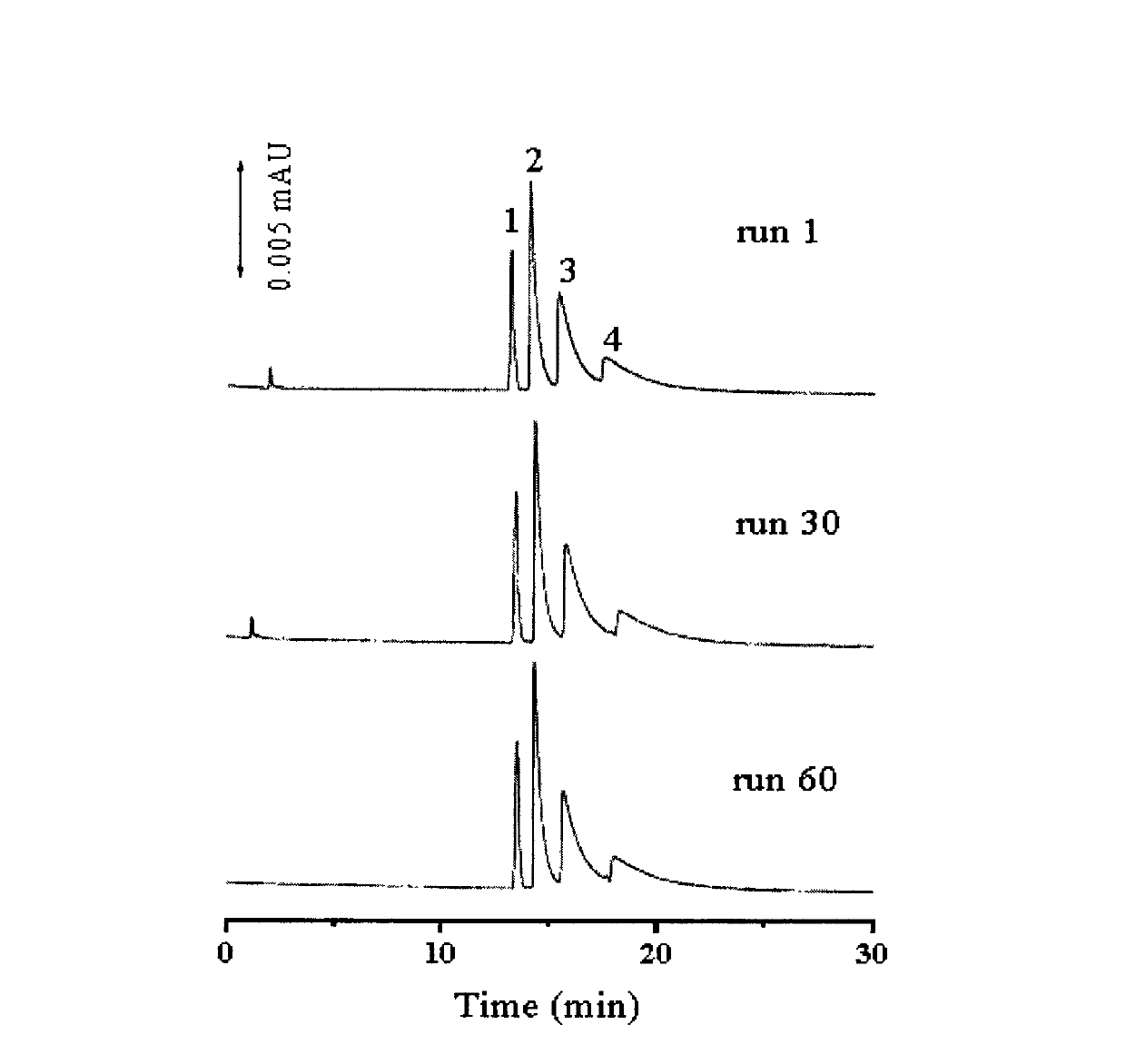

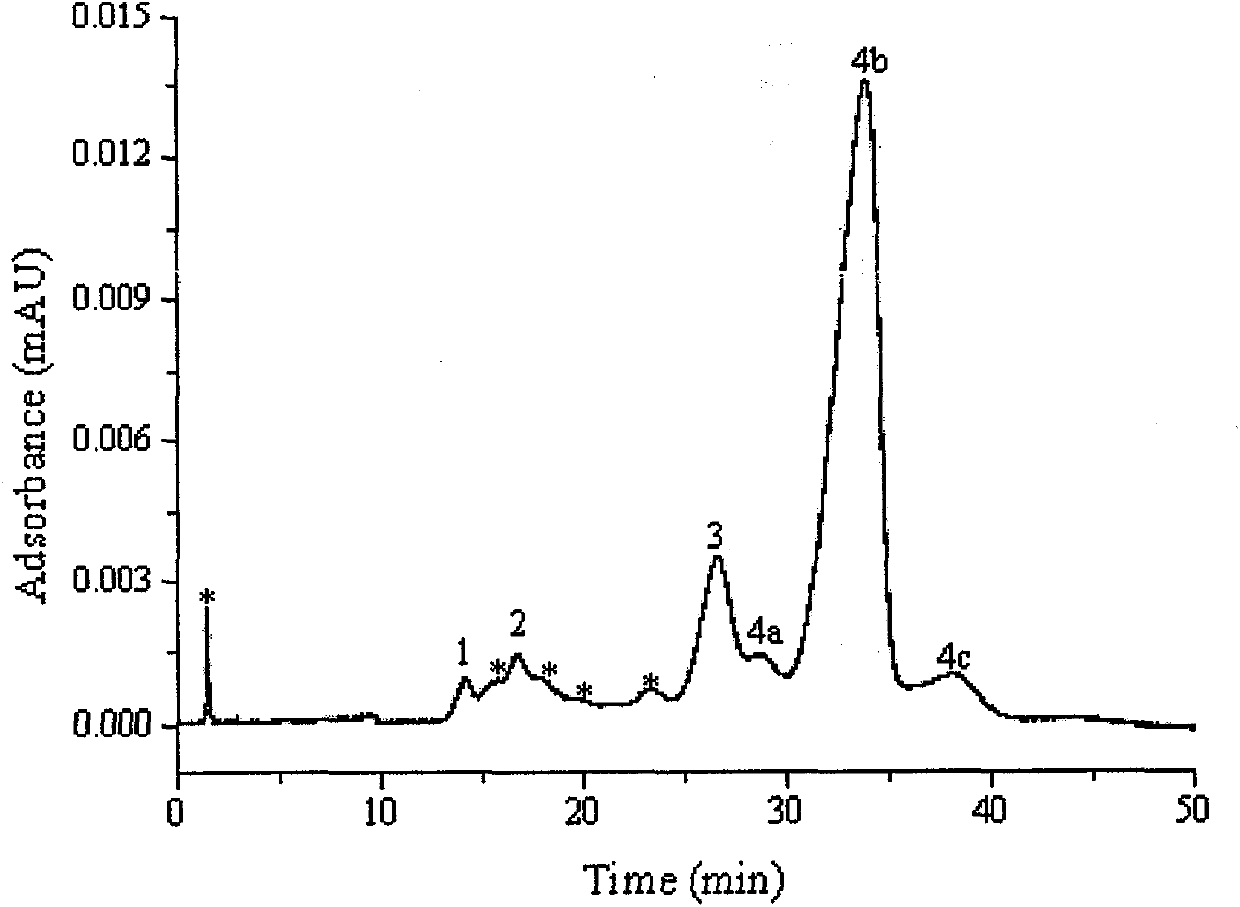

[0039] (3) Preparation of graphene-modified capillary column;

[0040] Graphene oxide and deionized water are prepared according to the ratio of 0.2%wt graphene oxide deposi...

Embodiment 2

[0049] All the other are identical with above-mentioned embodiment, difference is, a kind of preparation method of graphene modified capillary electrochromatographic column, concrete steps comprise as follows:

[0050] (1) Pretreatment of capillary;

[0051] Rinse the capillary with deionized water for 10 minutes, then rinse the capillary with NaOH solution for 4 hours, and then rinse with deionized water for 15 minutes;

[0052] (2) polyelectrolyte modified capillary inner wall;

[0053] Select a cationic electrolyte, prepare 8% (w / v) polydimethyldiallylammonium chloride solution, and add 0.5M KCl solution to it to form a cationic polyelectrolyte coating solution;

[0054] Inject the above prepared liquid into the pretreated capillary column within 5 minutes, and then rinse the capillary with deionized water for 5 minutes to form a cationic capillary column;

[0055] (3) Preparation of graphene-modified capillary column;

Embodiment 3

[0059] All the other are identical with above-mentioned embodiment, difference is, a kind of preparation method of graphene modified capillary electrochromatographic column, concrete steps comprise as follows:

[0060] (1) Pretreatment of capillary;

[0061] Rinse the capillary with deionized water for 5 minutes, then rinse the capillary with NaOH solution for 3 hours, and then rinse with deionized water for 5 minutes;

[0062] (2) polyelectrolyte modified capillary inner wall;

[0063] Select a cationic electrolyte, prepare a 5% (w / v) acrylamide acryloyloxyethyltrimethylammonium chloride copolymer P (AM AETAC)) solution, and add 0.1M NaCl solution to it to form a cationic Polyelectrolyte coating solution;

[0064] Inject the above prepared liquid into the pretreated capillary column within 3 minutes, and then rinse the capillary with deionized water for 5 minutes to form a cationic capillary column;

[0065] (3) Preparation of graphene-modified capillary column;

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com