Hydrolysis/aerobic cycle suspension activated sludge process and device for deep treatment of waste water

An activated sludge method and advanced treatment technology, applied in the field of water treatment, can solve the problems of high investment and complicated operation, achieve high sludge concentration, high treatment efficiency, and improve the effect of wastewater treatment depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

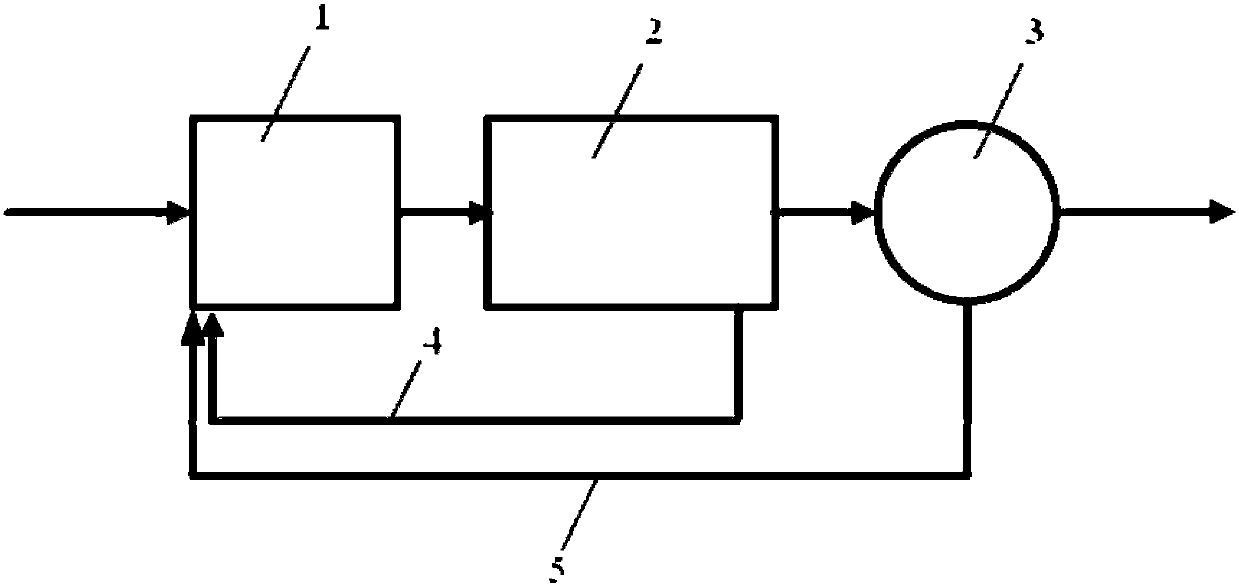

[0032] A waste water advanced treatment device, such as figure 1 shown. The wastewater advanced treatment device comprises a hydrolysis tank 1, an aerobic tank 2 and a secondary sedimentation tank 3, the outlet of the hydrolysis tank 1 is connected with the inlet of the aerobic tank 2, and the outlet of the aerobic tank 2 is connected with the secondary sedimentation tank 3 The inlet is connected, a first return pipe 4 is set from the aerobic tank 2 to the hydrolysis tank 1, and a second return pipe 5 is set from the secondary sedimentation tank 3 to the hydrolysis tank 1.

Embodiment 2

[0034] A petrochemical wastewater treatment project in Shandong: the wastewater contains petroleum, volatile phenols and alcohols, and the wastewater volume of the project is 2000-2500m 3 d -1 , Wastewater COD: 500-1500mg·L -1 , volatile phenol 50-150mg·L -1 , pH 8-9. The wastewater advanced treatment device of Example 1 was used to treat the production wastewater.

[0035] In the wastewater advanced treatment device: (1) The effective volume of the hydrolysis tank is 2300m 3, equipped with an underwater propeller for stirring, the power of the single machine is 2.2kw; (2) The effective volume of the aerobic pool is 3700m 3 , the aerobic tank is installed with HS strong shear aerators, arranged in a linear arrangement, and the aeration intensity is 16m 3 / min / 1000m 3 ; (3) The diameter of the secondary settling tank is 16m, and the surface load is 0.41-0.52m 3 / m 2 / h.

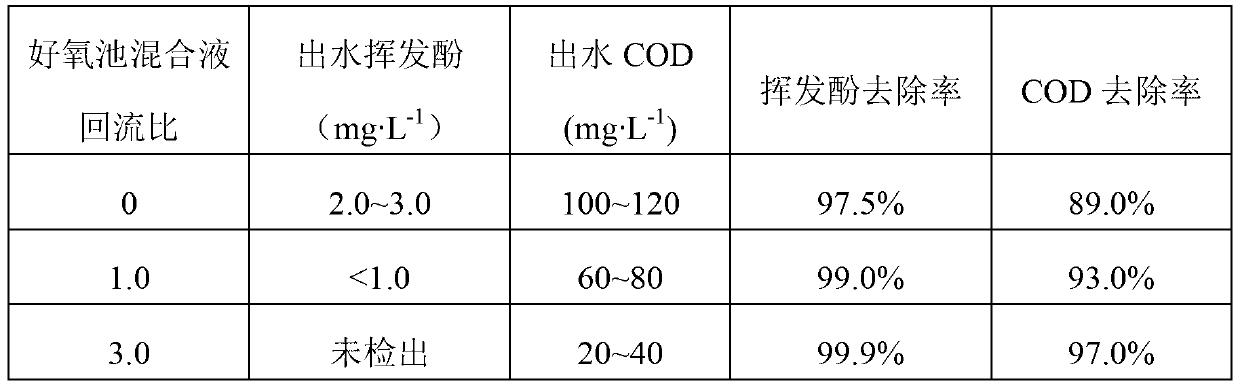

[0036] Since the waste water contains volatile phenol, a toxic and harmful substance, the volume r...

Embodiment 3

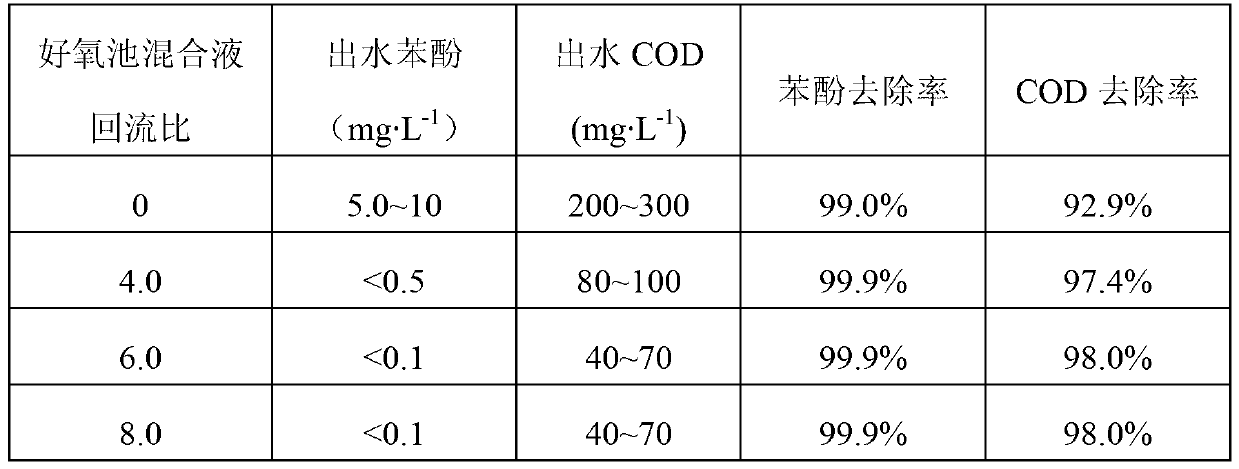

[0041] A pharmaceutical wastewater treatment project in Guizhou

[0042] The enterprise is a pharmaceutical company that mainly produces 10 kinds of production dosage forms including tablets, capsules, pills, granules, syrups, etc. The waste water mainly comes from the production process of Chinese patent medicines, and the water volume is 2400m 3 d -1 , COD concentration is 5000mg·L -1 . The wastewater advanced treatment device of Example 1 was used to treat the production wastewater.

[0043] In the wastewater advanced treatment device: (1) The effective volume of the hydrolysis tank is 4300m 3 , equipped with two underwater propellers (stirring function), the single unit power is 1.8kw; (2) The effective volume of the aerobic pool is 9000m 3 , the aerobic tank is equipped with HS strong shear aerators, arranged in a linear arrangement, and the aeration intensity is 26.9m 3 / min / 1000m 3 ; (3) The diameter of the secondary settling tank is 15m, and the surface load is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com