Gallium-nitride-based high electronic mobility transistor structure with barrier layer and manufacture method thereof

A high electron mobility, gallium nitride-based technology, applied in the field of GaN-based high electron mobility transistor structure and fabrication with a barrier layer, can solve the problems of increased interface roughness, reduced mobility, enhanced scattering, etc. , to achieve high two-dimensional electron gas surface density, increase the barrier height, and reduce the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

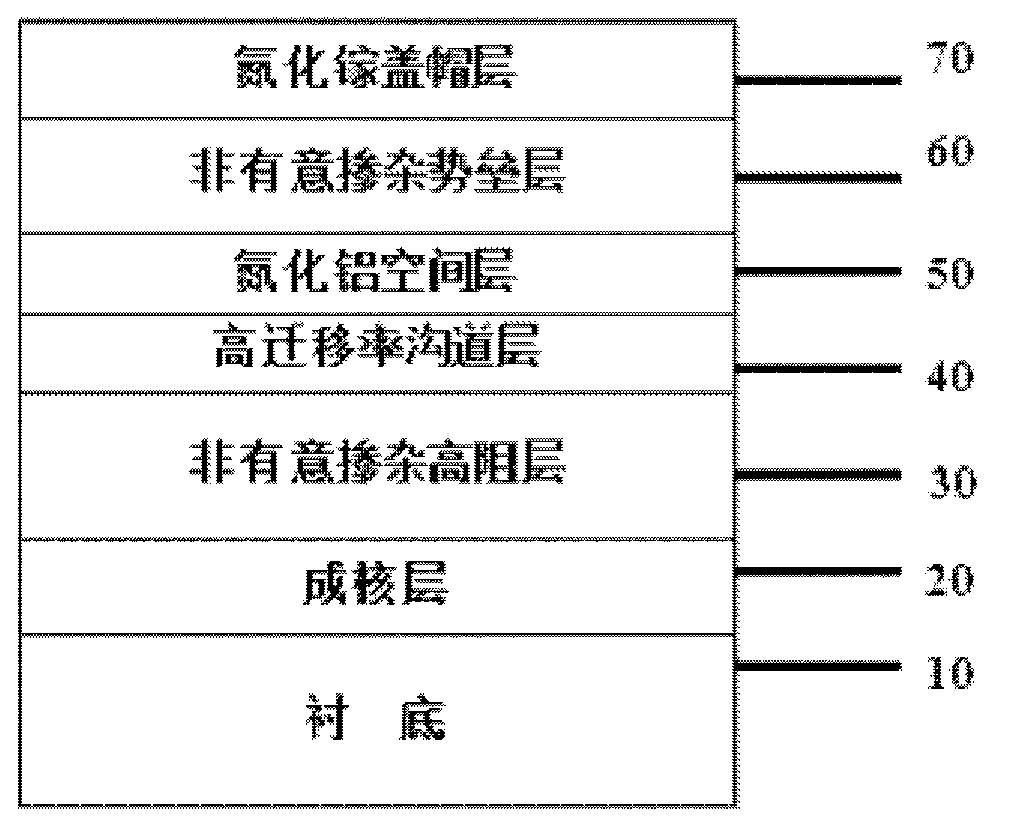

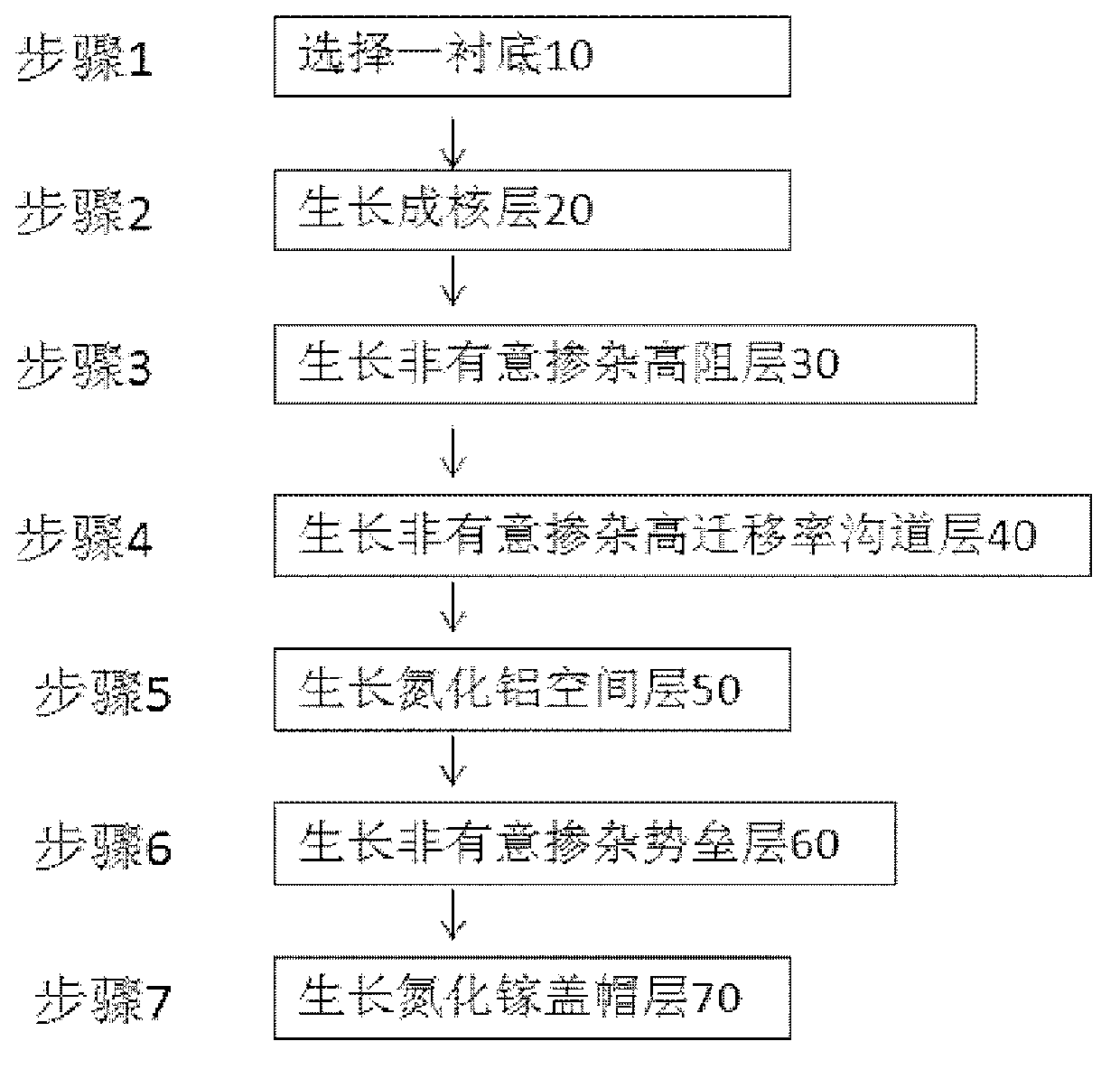

[0045] The present invention provides a GaN-based HEMT structure with a barrier layer, which includes:

[0046] A substrate 10, the material of which is sapphire.

[0047] A nucleation layer 20 is formed on the substrate 10 . The material of the nucleation layer 20 is low-temperature gallium nitride with a thickness of 100 nm;

[0048] An unintentionally doped high-resistance layer 30 is fabricated on the nucleation layer 20 . The aluminum composition y of the unintentionally doped high resistance layer 30 is 0, the material of the unintentionally doped high resistance layer 30 is gallium nitride, and the thickness is 3 μm.

[0049] An unintentionally doped high mobility channel layer 40 is fabricated on the unintentionally doped high resistance layer 30 . The material of the non-intentionally doped high-mobility layer channel layer 40 is gallium nitride with a thickness of 30 nm.

[0050] An unintentionally doped AlN space layer 50 , the unintentionally doped AlN space la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com