Method for transferring nano-particles from oil phase into aqueous phase

A nanoparticle, water phase technology, applied in separation methods, chemical instruments and methods, liquid displacement, etc., can solve the problem of difficult to remove oxidants, achieve excellent solubility and physiological compatibility, uniform size without change , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

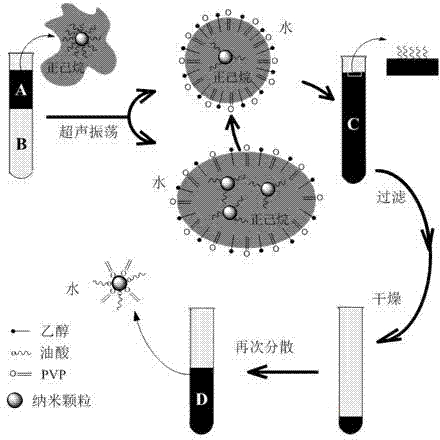

Method used

Image

Examples

Embodiment 1

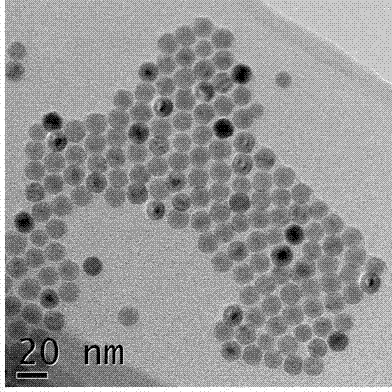

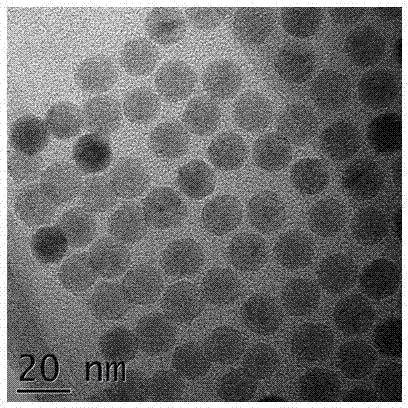

[0034] Monodisperse magnetic g-Fe coated with oleic acid 2 O 3 The nanoparticles were dispersed in a n-hexane solvent to obtain an oil-phase nanoparticles-n-hexane solution with a concentration of 9 mg / ml. Mix 25 ml of deionized water with 5 ml of absolute ethanol, and add 0.5 g of PVP to make an aqueous solution. Take 10 ml of the oil phase solution and mix the water phase solution and place it in a container with the oil phase solution in the upper layer and the water phase solution in the lower layer. Vigorously ultrasonically oscillate the mixed solution of the oil phase solution and the water phase solution for 45 minutes to obtain an oil-in-water microemulsion. The small amount of oil on the liquid surface of the microemulsion is oleic acid which is detached from the surface of the nanoparticles by ultrasonic vibration. Filter to remove a small amount of insoluble matter and oleic acid to obtain a uniform and stable microemulsion. The microemulsion can continue to be ev...

Embodiment 2

[0036] Monodisperse magnetic g-Fe coated with oleic acid 2 O 3 The nanoparticles were dispersed in a n-hexane solvent to obtain an oil-phase nanoparticles-n-hexane solution with a concentration of 9 mg / ml. Mix 25 ml of deionized water with 5 ml of absolute ethanol, and add 0.5 g of PVP to make an aqueous solution. Take 10 ml of the oil phase solution and mix the water phase solution and place it in a container with the oil phase solution in the upper layer and the water phase solution in the lower layer. Vigorously ultrasonically oscillate the mixed solution of the oil phase solution and the water phase solution for 45 minutes to obtain an oil-in-water microemulsion. The small amount of oil on the liquid surface of the microemulsion is oleic acid which is detached from the surface of the nanoparticles by ultrasonic vibration. Filter to remove a small amount of insoluble matter and oleic acid to obtain a uniform and stable microemulsion. The microemulsion can continue to be ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com