Synthetic method of water-solubility biocompatibility monodisperse spherical gold nanometer crystals

A biocompatible, monodisperse technology, applied in the field of gold nanocrystal synthesis, can solve the problems of wide particle size distribution, unsatisfactory effect, inability to achieve high sensitivity, etc., and achieve the effect of good repeatability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Soak the used glassware (100ml double-necked flask and 5ml serum bottle) in aqua regia for 2 hours, rinse with saturated sodium nitrate solution and ultrapure water several times, and dry them for later use. Using ultrapure water to calibrate with ultraviolet-visible spectroscopy, a 1% chloroauric acid solution was prepared. The required raw materials sodium citrate and silver nitrate were respectively configured into solutions with ultrapure water, wherein the mass percentage concentration of the sodium citrate solution was 3%, and the mass percentage concentration of the silver nitrate solution was 0.02%. In this example, glutathione was used as a stabilizer to stabilize gold nanocrystals, and a glutathione solution with a concentration of 1.5% by mass was prepared with ultrapure water. Then 47.5 milliliters of ultrapure water was placed in a 100 milliliter two-necked bottle, and heated rapidly to boiling. Then add 1.0 ml of ultrapure water, 0.5 ml of sodium citrate ...

Embodiment 2

[0018] Soak the used glassware (100ml double-necked flask and 5ml serum bottle) in aqua regia for 2 hours, rinse with saturated sodium nitrate solution and ultrapure water several times, and dry them for later use. With embodiment 1, preparation mass percentage concentration is the chloroauric acid solution of 1%, the mass percentage concentration is the sodium citrate solution of 2%, the mass percentage concentration is the silver nitrate solution of 0.01%. Place 47.5 ml of ultrapure water in a 100 ml two-necked bottle and heat it rapidly to boiling. Then 0.325 milliliters of ultrapure water, 1.25 milliliters of sodium citrate solution, 0.5 milliliters of chloroauric acid solution and 0.425 milliliters of silver nitrate solution were added to the 5 milliliter serum bottle for mixed reaction, and the color of the reaction solution changed from light yellow to dark green ( about 16 minutes), quickly transfer to boiling water. Keep boiling, heat to reflux for 30 minutes, and co...

Embodiment 3

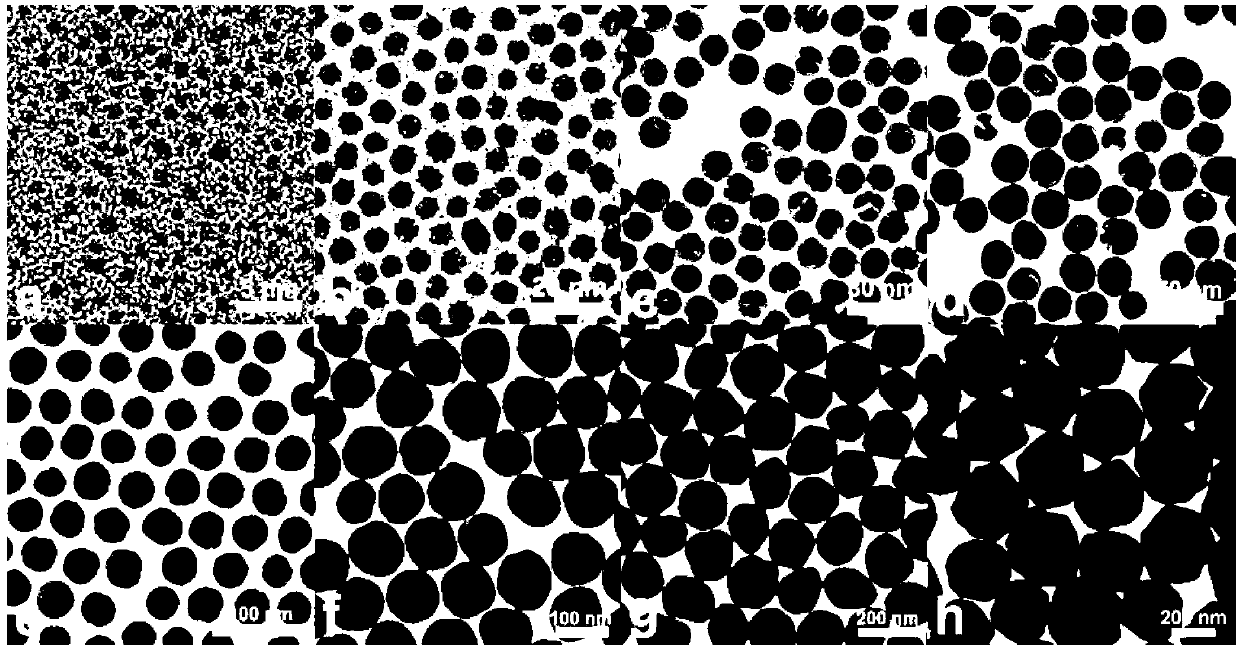

[0020] With embodiment 1, preparation mass percentage concentration is the chloroauric acid solution of 1%, the mass percentage concentration is the sodium citrate solution of 3%, the mass percentage concentration is the silver nitrate solution of 0.08%. Place 47.5 ml of ultrapure water in a 100 ml two-necked bottle and heat it rapidly to boiling. Then add 1.075 ml of ultrapure water, 0.5 ml of sodium citrate solution, 0.5 ml of chloroauric acid solution and 0.425 ml of silver nitrate solution into a 5 ml serum bottle, mix and react for 5 minutes, then quickly transfer and inject into boiling water. Keep boiling, heat to reflux for 45 minutes, and cool to room temperature to obtain monodisperse spherical gold nanocrystals with a particle size of 12±1 nm. The transmission electron micrograph of the obtained gold nanocrystals is shown in c in the accompanying drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com