Preparation method of high polymer product provided with multi-scale foam structure and applications of high polymer product provided with multi-scale foam structure

A multi-scale, high-molecular technology, applied in the field of foamed high-molecular product preparation, can solve the problems of inability to obtain high-molecular materials, mass production, and low production efficiency, and achieve the effect of easy promotion, mass production, and fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

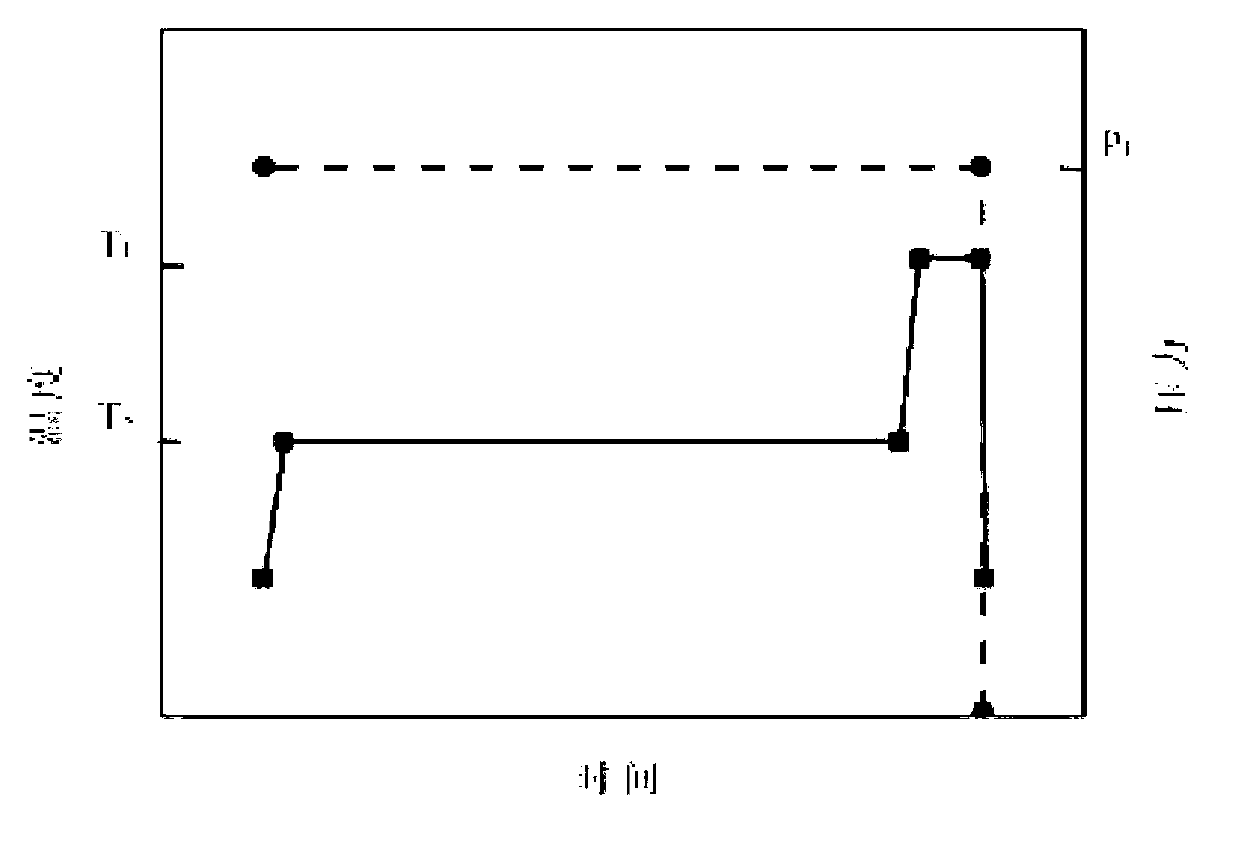

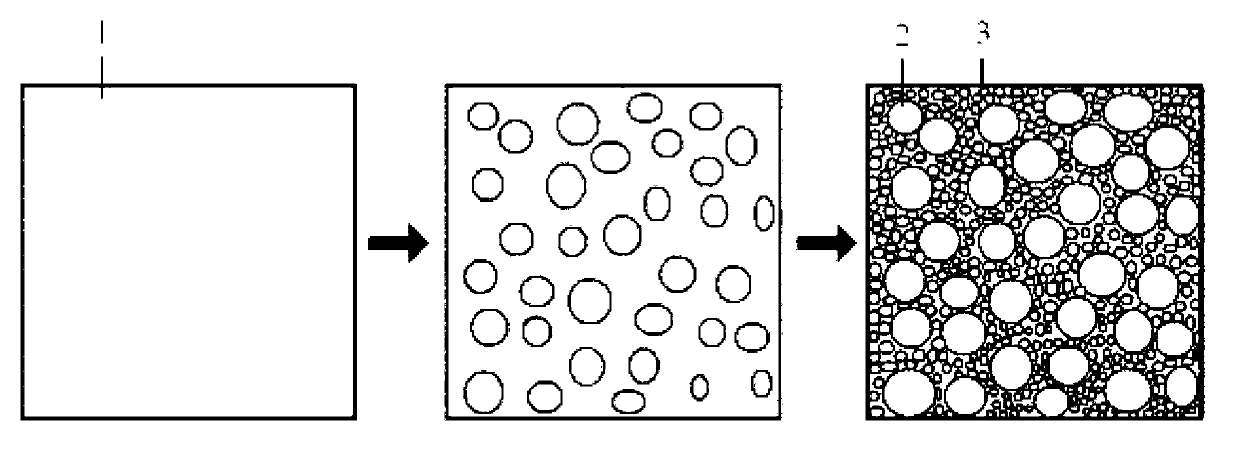

[0047] In this embodiment, a method for preparing a polymer product with a double-scale cell structure includes the following steps:

[0048] (1) Add PS (polystyrene) pellets into the extruder, and extrude to prepare PS rod-like splines with a diameter of about 1mm and a length of 10mm;

[0049] (2) Put the PS rod-shaped sample prepared in step (1) into the autoclave, and pass supercritical CO 2 , after continuous saturation for 5 hours, the temperature was raised to the foaming temperature of 100°C, and after being maintained for 40 minutes, the pressure in the autoclave cavity was reduced to atmospheric pressure within 1 second to obtain a PS product with a double-scale cell structure.

[0050] Figure 6A and Figure 6B Shown is a scanning electron micrograph of the PS prepared above. It can be seen from the figure that a double-scale cell structure is formed in the prepared PS product, the average diameter of the large and small cells is about 50.0 μm and 10.5 μm, and th...

Embodiment 2

[0053] This embodiment is a method for preparing a polymer product with a double-scale cell structure, comprising the following steps:

[0054] (1) Add PLA (polylactic acid) pellets into the extruder, and extrude to prepare a PLA rod-shaped strip with a diameter of about 1mm and a length of 10mm;

[0055] (2) Put the PLA rod-shaped strip prepared in step (1) into the autoclave, and pass supercritical CO 2 , after continuous saturation for 3 hours, the temperature was raised to the foaming temperature of 150°C, and after being maintained for 40 minutes, the pressure in the autoclave cavity was reduced to atmospheric pressure within 1 second to obtain a PLA product with a double-scale cell structure.

[0056] Figure 8A and Figure 8B Scanning electron micrographs of the PS prepared above. It can be seen from the figure that the double-scale cell structure with open cells is formed after PLA foaming.

Embodiment 3

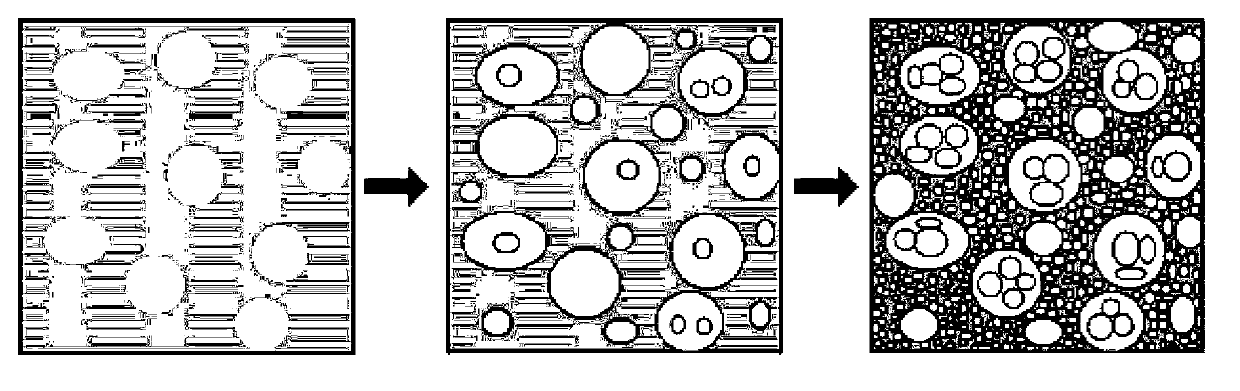

[0058] In this embodiment, a method for preparing a polymer product with a double-scale cell structure includes the following steps:

[0059] (1) Weigh 70 parts of PS and 30 parts of PLA by volume and mix them together;

[0060] (2) Add the mixture of step (1) into the extruder and extrude to prepare a PS / PLA blend with a diameter of about 1mm and a length of 10mm;

[0061] (3) Put the PS / PLA blend prepared in step (2) into the autoclave, and feed supercritical CO 2 , after continuous saturation for 3 h, the temperature was raised to 150 °C for foaming, and after maintaining for 40 min, the pressure in the autoclave cavity was reduced to atmospheric pressure within 1 s to obtain a foamed PS / PLA blend with a double-scale cell structure.

[0062] Figure 9A and Figure 9B Shown is a scanning electron micrograph of the PS / PLA blend prepared above. It can be seen from the figure that the foamed blend presents a double-scale cell structure. According to statistics, the average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com