Preparation method of nano-cellulose aerogel

A nanocellulose and aerogel technology is applied in the field of preparation of nanocellulose aerogel, which can solve the problems of poor dispersibility of cellulose aerogel, and achieve the effects of low cost, simple preparation method and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of nanocellulose airgel in this embodiment is implemented according to the following steps:

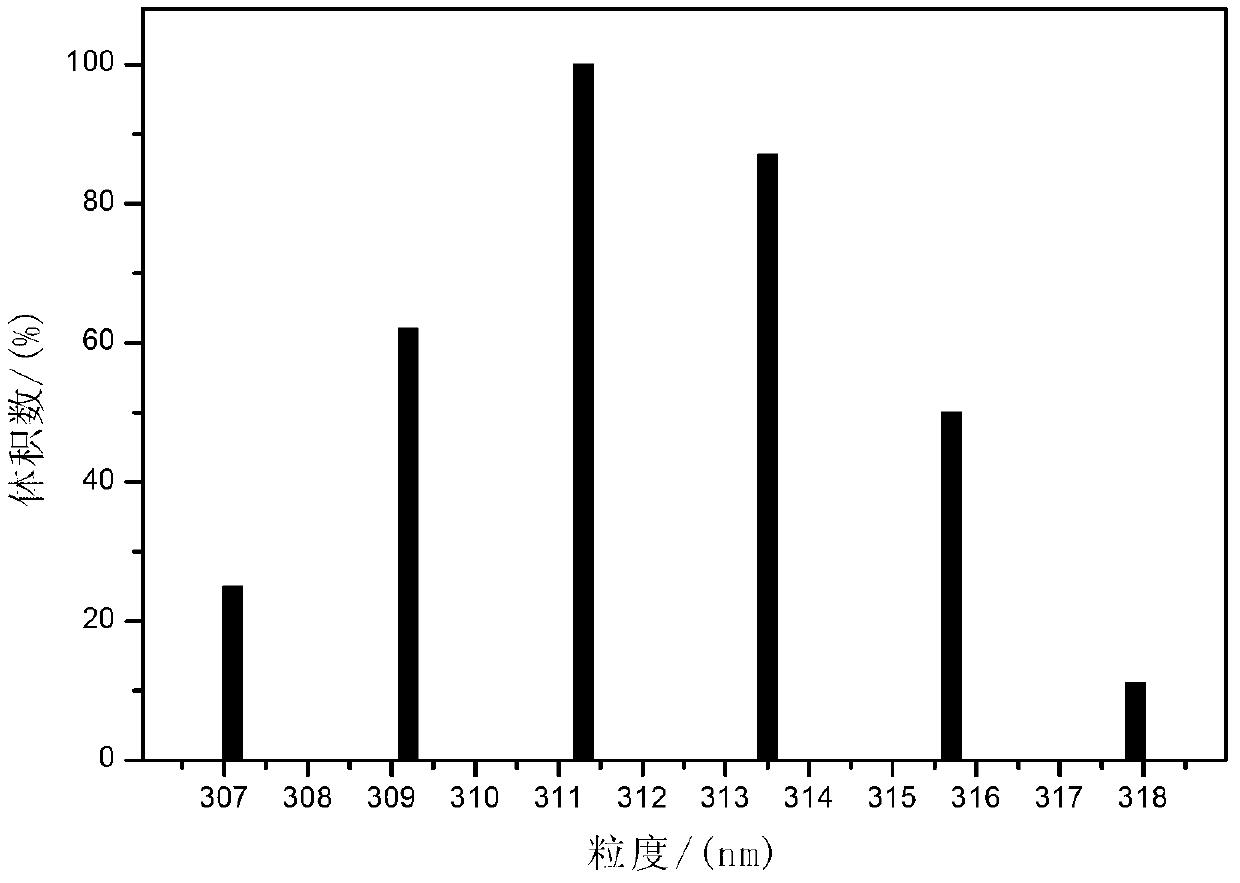

[0018] 1. Dissolve absorbent cotton in a sulfuric acid solution with a mass fraction of 55% and acidify it for 3 to 6 hours to obtain a nanocellulose suspension. Centrifuge the nanocellulose suspension at a speed of 6000 to 10000 r / min for 8 to 15 minutes to obtain a white sol precipitate. Use deionized water to repeatedly wash the white sol precipitation to neutrality to obtain nanocellulose sol precipitation;

[0019] 2. According to the volume ratio of nano-cellulose sol precipitation and organic solvent as 1: (10-50), add the nano-cellulose sol precipitation in step 1 into the organic solvent, stir at 800r / min-1000r / min for 8-15min Put it into an ultrasonic cleaner and disperse it ultrasonically at 45 Hz for 5-10 minutes to obtain a suspension of nanocellulose dispersed in an organic solvent;

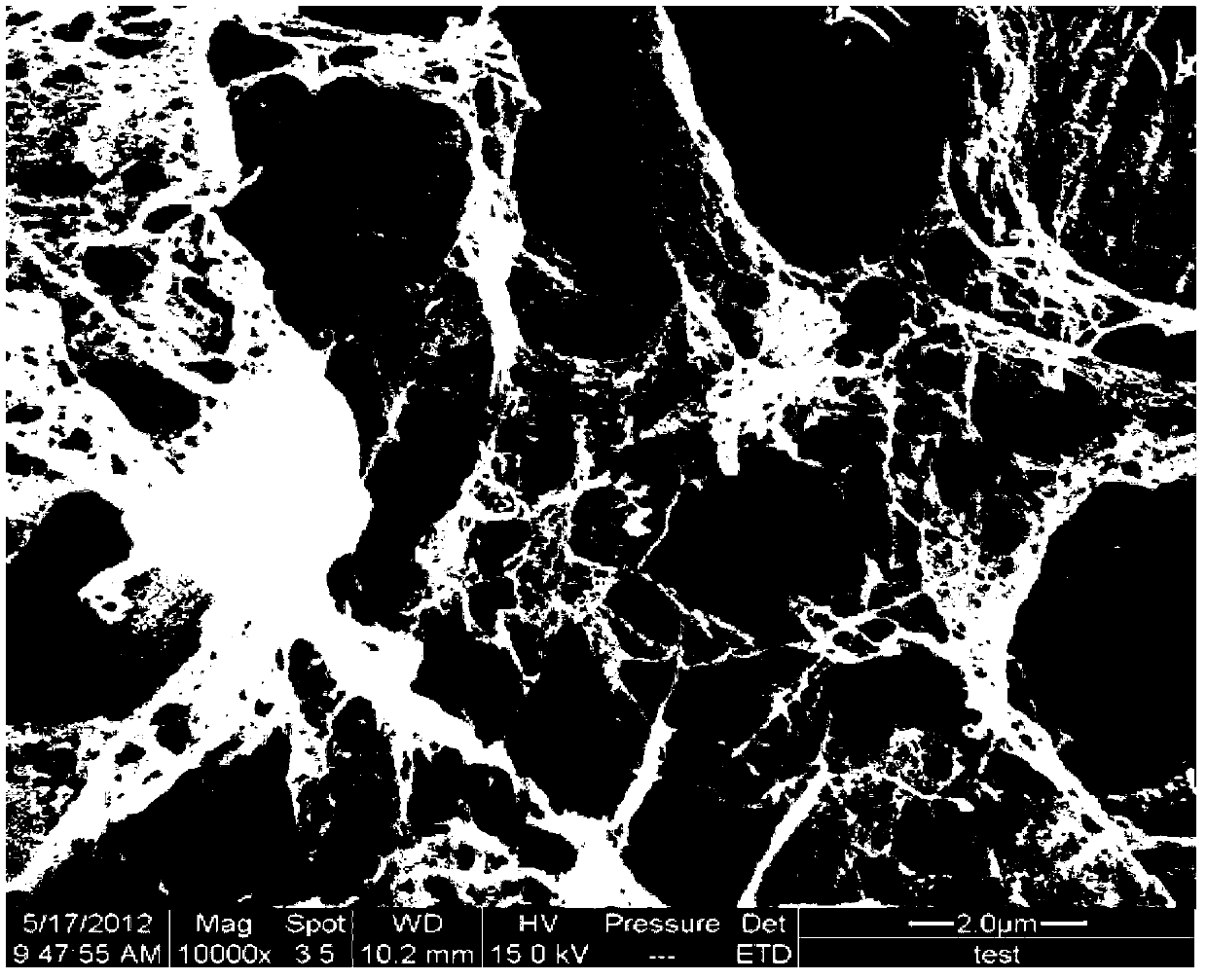

[0020] 3. Freeze the nanocellul...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 1, 2.0 g of absorbent cotton is dissolved in 100 mL of sulfuric acid solution with a mass fraction of 55% for acid hydrolysis. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the absorbent cotton is dissolved in a sulfuric acid solution with a mass fraction of 55%, and acidolyzed at 50°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com