polyacetal resin composition

A technology of polyacetal resin and composition, applied in the field of polyacetal resin composition, can solve the problems of reducing the generation of formaldehyde, insufficiently speaking, impairing the surface smoothness and surface roughness of molded products, etc. Effects of excellent wear characteristics, good surface smoothness, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the graft copolymer is not particularly limited, and it can be easily prepared by a known radical reaction. For example, the graft copolymer (D) can be prepared by adding a radical catalyst to the monomers constituting (d1) and monomers constituting (d2) and kneading for grafting, or adding (d1) ) component or (d2) component, adding a radical catalyst such as a peroxide to generate free radicals, which is melt-kneaded with a polymer of another component to graft the method, etc.

[0057] The ratio of (d1) olefin-based polymer to (d2) vinyl-based polymer constituting (D) the graft copolymer is preferably d1:d2=80:20 to 20:80 (mass ratio), particularly preferably d1 :d2=60:40~40:60.

[0058] In this invention, the compounding quantity of the said (D) graft copolymer is 2-10 mass parts with respect to 100 mass parts of (A) polyacetal resins. (D) When the compounding quantity of a component is less than 2 mass parts, the improvement effect of the...

Embodiment

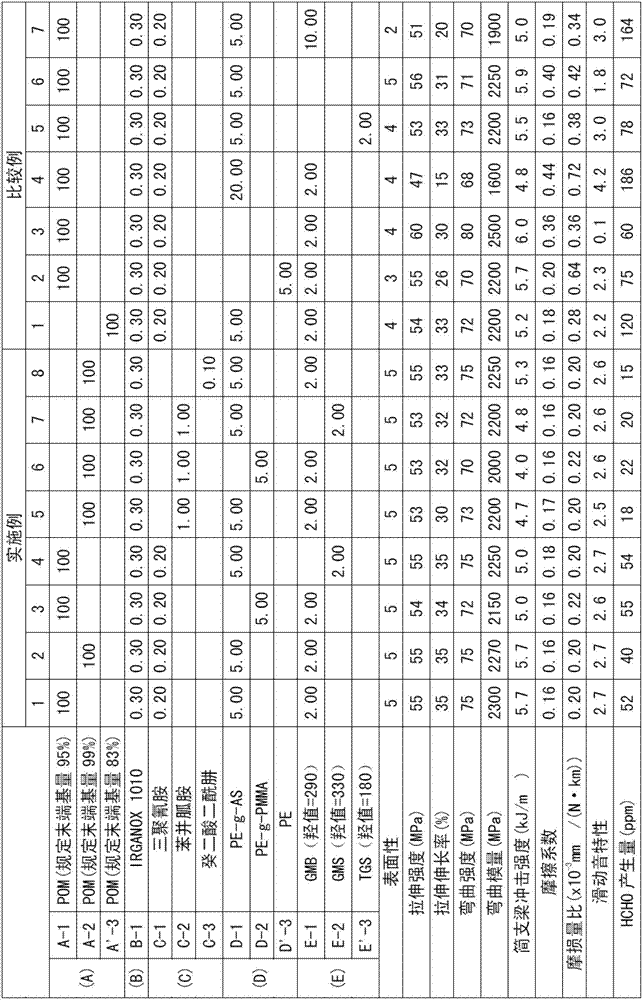

[0077] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples.

[0078] Examples and Comparative Examples

[0079] Details of each component used in Examples and Comparative Examples are as follows.

[0080] (A) Polyacetal resin (POM):

[0081] A-1: Copolymer of 96.7% by mass trioxane / 3.3% by mass of 1,3-dioxolane (with respect to all terminal groups, the ratio of the total amount of methoxyl end groups and hydroxyethoxyl end groups is 95%)

[0082] A-2: Copolymer of 96.7% by mass trioxane / 3.3% by mass of 1,3-dioxolane (with respect to all terminal groups, the ratio of the total amount of methoxyl end groups and hydroxyethoxyl end groups is 99%)

[0083] A'-3: Copolymer of 96.7% by mass trioxane / 3.3% by mass of 1,3-dioxolane (ratio of the total amount of methoxy end groups and hydroxyethoxy end groups to all end groups was 83%)

[0084] The preparation method of polyacetal resin A-1

[0085] A mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com