Super-hydrophobic propping agent and preparation method

A proppant and super-hydrophobic technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems affecting the surface modification effect of proppant, achieve high production efficiency, improve oil recovery, and product The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

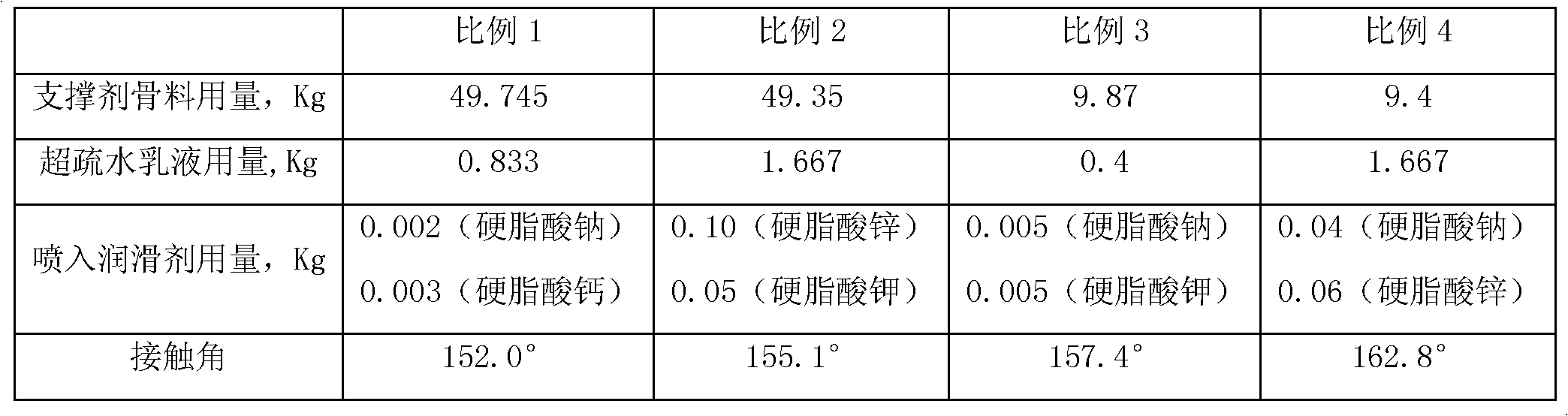

Embodiment 1

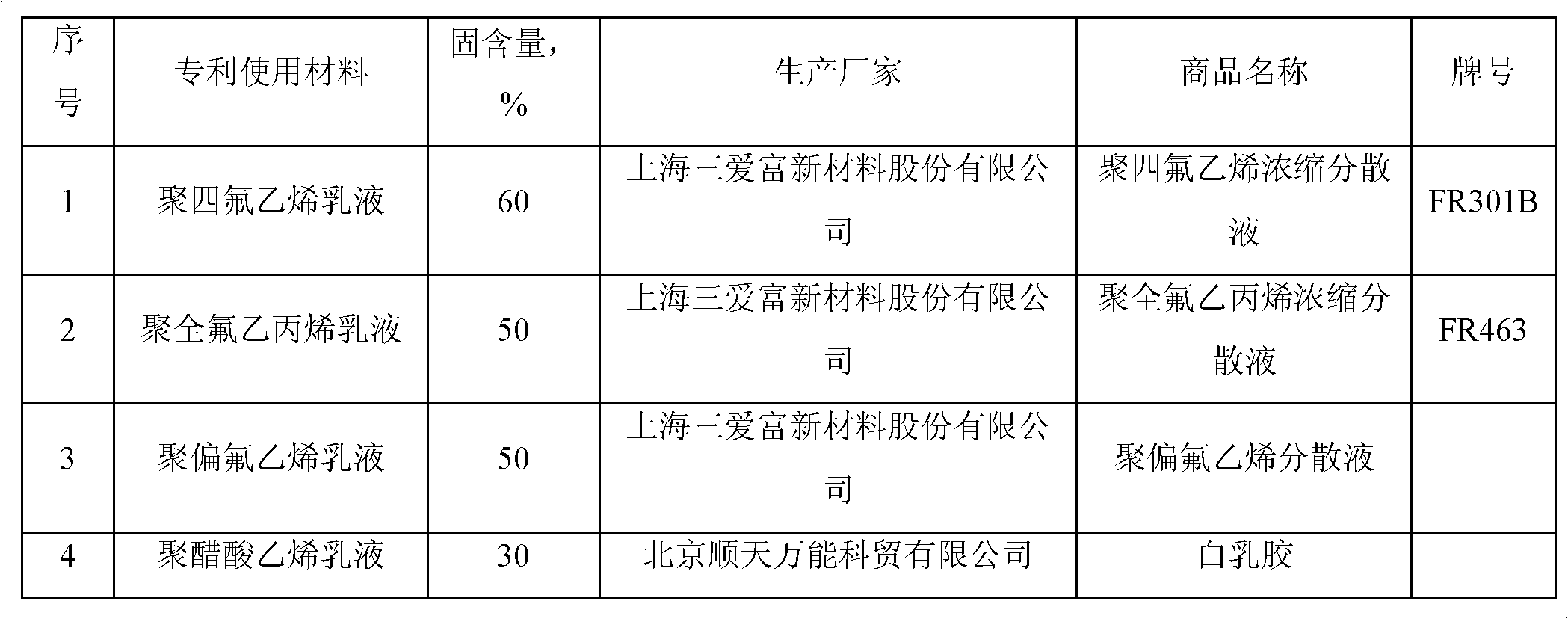

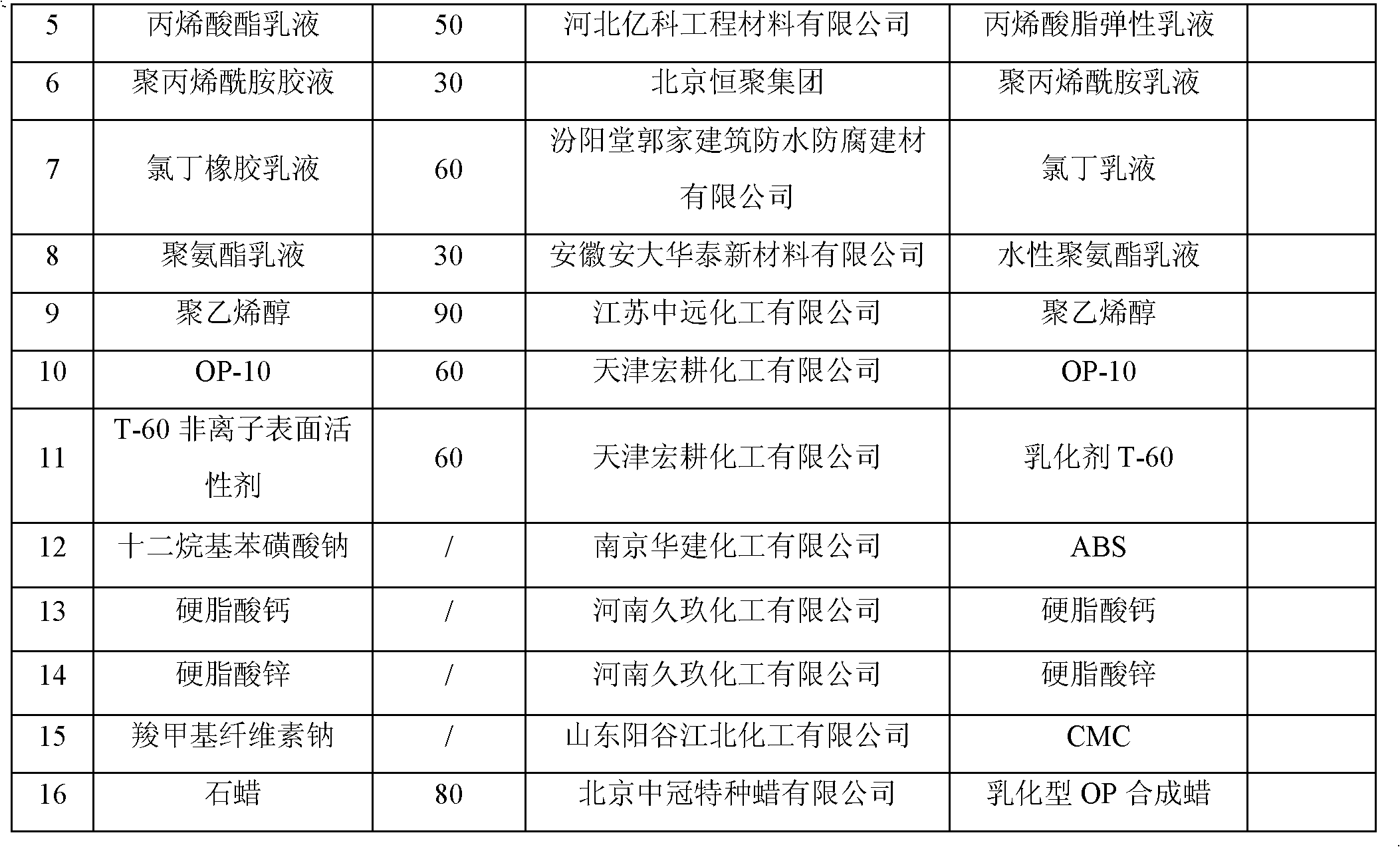

[0051] (1) Preparation of superhydrophobic emulsion: Weigh 200.0 grams of polytetrafluoroethylene emulsion and 100.0 grams of polyvinylidene fluoride emulsion, and add 100.0 grams of polyvinyl acetate emulsion, 90.0 grams of polyvinyl alcohol, and OP-10 surfactant in sequence while stirring 1.0 g, then add 509.0 g of distilled water, stir at a speed of 600 r / min for 30 minutes and set aside. A total of 1000 grams of the superhydrophobic emulsion prepared in this way (wherein the solid content is 281.6 grams / 1000 grams), about 1000ml.

[0052] (2) Processing and molding of super-hydrophobic membrane: Weigh a certain amount (see Table 2) of ceramsite proppant (particle size 0.42-0.84mm), and put it into the fluidized bed; turn on the fan and heating device of the fluidized bed, and the air volume of the fan It can keep the proppant in the fluidized bed fully boiling and flowing, and the hot air temperature is set at 300°C; when the temperature difference between the air outlet a...

Embodiment 2

[0058] (1) Superhydrophobic emulsion preparation: Weigh 200.0 grams of polytetrafluoroethylene emulsion, 200 grams of polyfluoroethylene propylene emulsion, and add 30.0 grams of polyvinyl acetate emulsion, 20.0 grams of acrylate emulsion, and 50.0 grams of polyvinyl alcohol in sequence while stirring 1. 2.0 grams of sodium dodecylbenzenesulfonate, then add 498.0 grams of distilled water, and stir for 30 minutes at a speed of 600 r / min for later use. A total of 1000 grams of the superhydrophobic emulsion prepared in this way (solid content is 286 grams / 1000 grams of emulsion), about 1000ml.

[0059] (2) Super-hydrophobic membrane processing and forming: Weigh a certain amount (see Table 3) of ceramsite proppant (particle size 0.149 ~ 0.25mm), and put it into the fluidized bed; turn on the fan and heating device of the fluidized bed, and the air volume of the fan The proppant in the fluidized bed can be kept fully boiling and flowing, and the hot air temperature is set at 250°C...

Embodiment 3

[0065] (1) Superhydrophobic emulsion preparation: Weigh 200 grams of polyvinylidene fluoride emulsion, 100.0 grams of polytetrafluoroethylene emulsion, and add 200.0 grams of polyvinyl acetate emulsion, 200.0 grams of polyacrylamide glue, dodecyl Add 20.0 grams of sodium benzenesulfonate, then add 280.0 grams of distilled water, stir at a speed of 600 r / min for 30 minutes and set aside. A total of 1000 grams of the superhydrophobic emulsion prepared in this way (solid content is 300 grams / 1000 grams of emulsion), about 1000ml.

[0066] (2) Super-hydrophobic membrane processing and forming: Weigh a certain amount (see Table 4) of quartz sand proppant (particle size 0.42-1.0mm), and put it into the fluidized bed; turn on the fan and heating device of the fluidized bed, and the air volume of the fan The proppant in the fluidized bed can be kept fully boiling and flowing, and the temperature of the hot air is set at 300°C; when the temperature difference between the air outlet and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com