Amorphous state nickel base alloy nucleating agent used for inoculation processing casting aluminium alloy and preparation method thereof

A technology for casting aluminum alloy and amorphous nickel, which is applied in the field of new nickel-based amorphous alloy inoculant and its preparation, and achieves the effects of shortening solidification time, facilitating dispersion and uniformity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

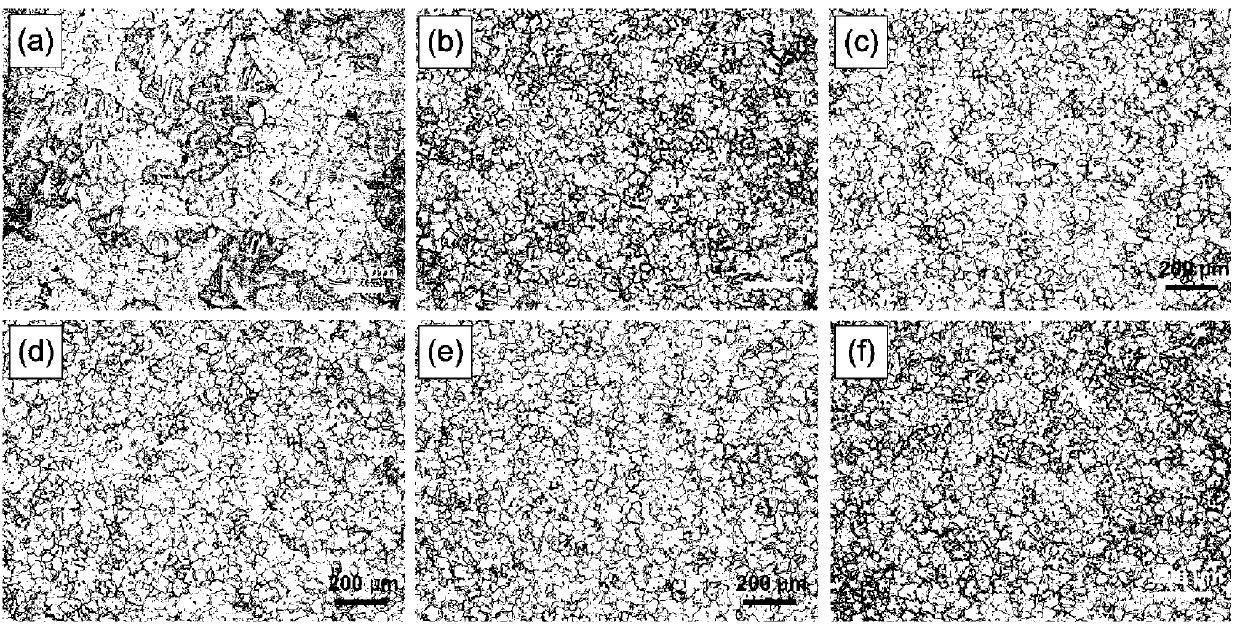

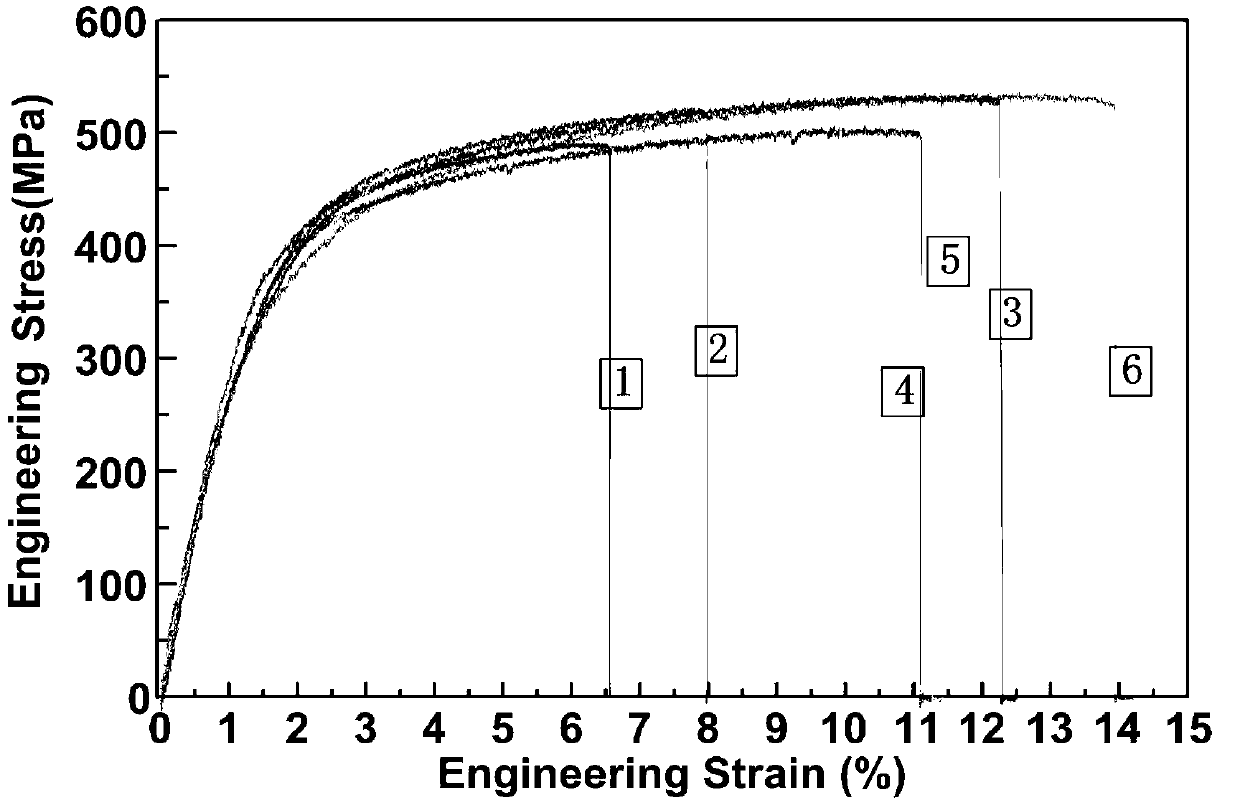

[0021] The specific content and implementation of the present invention are further described below with reference to the embodiments described in the accompanying drawings.

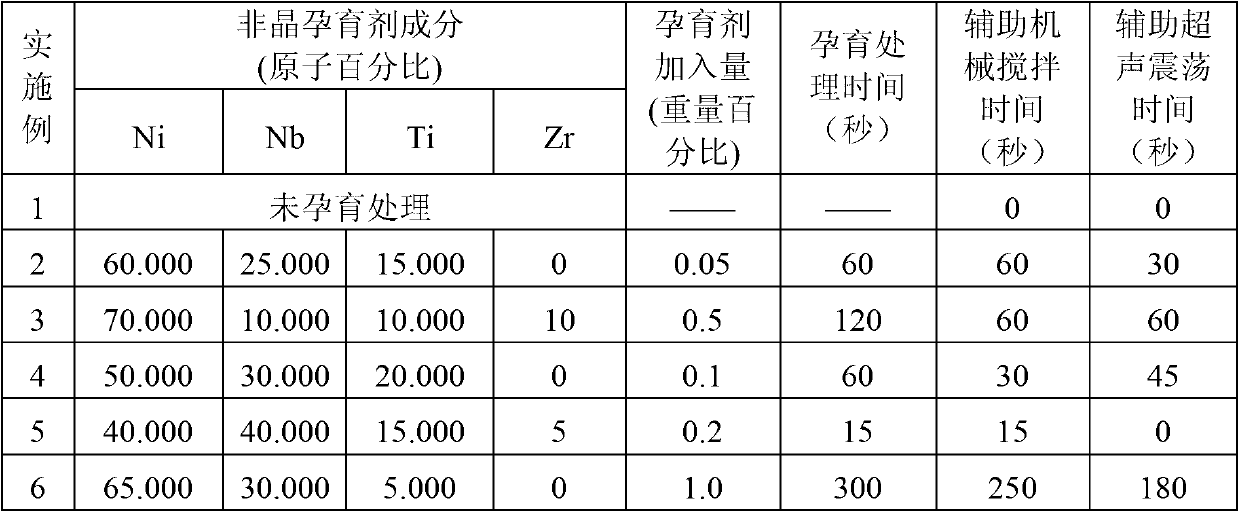

[0022] The present invention is a novel amorphous alloy inoculant for casting aluminum alloy, which is composed of the following components in atomic percentage: Ni: 40.000-70.000; Nb: 10.000-40.000; Ti: 5.000-20.000; Zr: 0.000-10.000.

[0023] The new amorphous nickel-based multi-alloy inoculant for casting aluminum alloys utilizes the metastable structure of amorphous alloys and the physical properties of amorphous crystallization, the physical phenomenon that amorphous crystallizes into small clusters or nanocrystals when heated The number of heterogeneous nucleation cores of the α-Al phase in the aluminum alloy melt is greatly increased instantaneously, and the α-Al grains are refined.

[0024] The technical scheme of the invention is as follows: the alloy elements of Ni, Nb, Ti and Zr are proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com