Electromagnetic induction heating rotary kiln

An electromagnetic induction heating and rotary kiln technology, which is applied in lighting and heating equipment, rotary drum furnaces, climate change adaptation, etc., can solve the problem of low production efficiency and processing capacity per unit time, inability to accurately control the working temperature of the rotary kiln, and effective operation of the equipment Short cycle time and other issues, to achieve the effect of fast kiln cleaning speed, reduction of heat radiation and heat loss, and long working cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

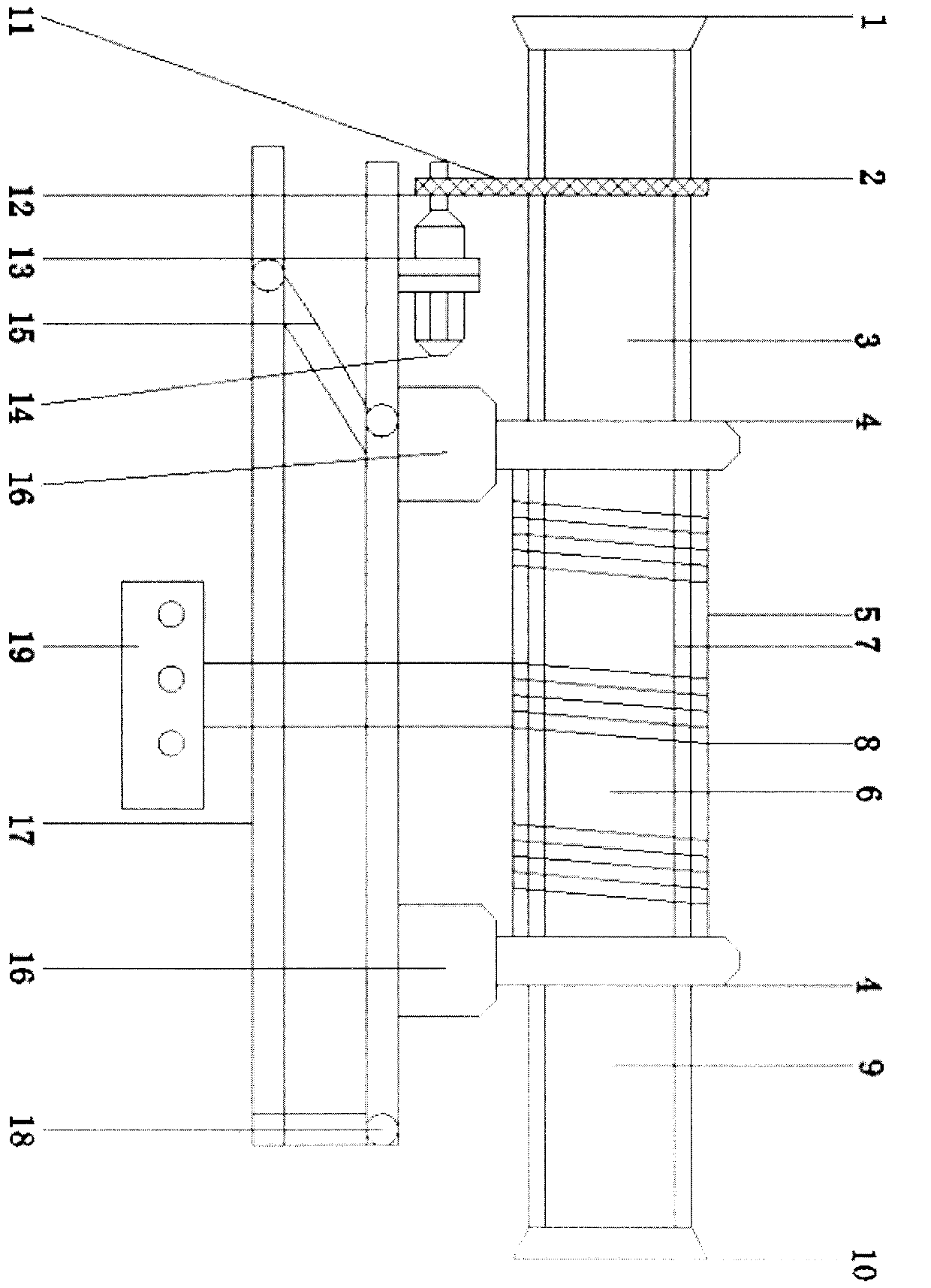

[0018]In the figure, the kiln body is composed of a feed inlet (1), a large tooth plate (2), a preheating zone (3), a heating zone (6), a cooling zone (9), and a discharge port (10). The kiln body is made of magnetic, conductive, and high-temperature-resistant materials. The kiln body for special purposes is made of magnetic, conductive, and high-temperature-resistant materials lined with high-temperature-resistant stainless steel composite materials. The surface of the kiln body is wrapped with heat-insulating materials (7) to reduce the The thermal radiation improves thermal efficiency. The large tooth plate (2) is installed on the preheating zone (3) between the feed inlet (1) and the heating zone (6), and a screw feeder is installed in the kiln body preheating zone (3) for feeding The material is uniformly transported from the feed port (1) to the heating zone (6). Two high temperature resistant bearings (4) are respectively installed between the kiln body preheating zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com