Enzyme method for extracting ginsenoside and obtained ginsenoside extractive

A ginsenoside and enzymatic extraction technology, applied in the directions of drug combinations, pharmaceutical formulations, plant raw materials, etc., can solve the problems of insufficient extraction of active ingredients, long extraction time, and complicated operations, and achieve full and comprehensive saponin components and high extraction rate. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

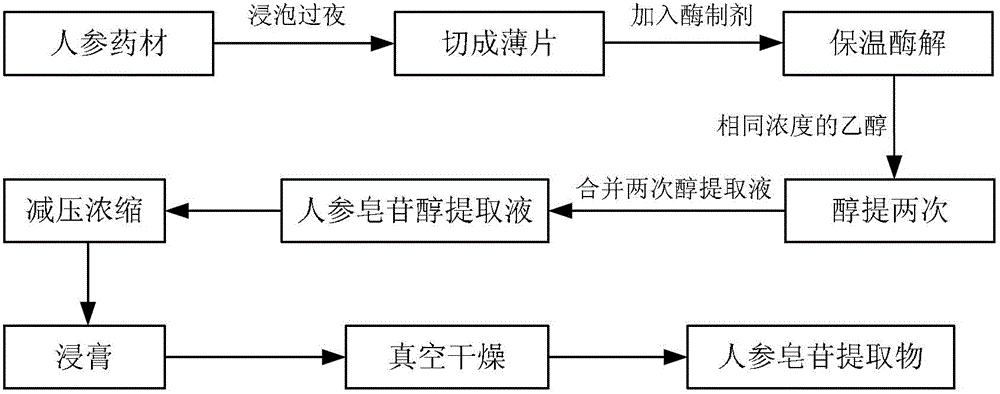

[0039] See figure 1 As shown in the extraction process, the enzymatic extraction of ginsenosides in this embodiment is mainly carried out as follows:

[0040] Weigh 100g of ginseng medicinal material, soak overnight, cut into thin slices, add 400mL of water, add 50mg of cellulase, 100mg of pectinase, react at 45°C for 1 hour, then add 200mL of 95% ethanol to the enzymolysis extract to form The ethanol extract was refluxed at 55°C for 3 hours, and the extract was obtained by filtration; the residue was refluxed at 55°C for 2 hours with 800 mL of ethanol solution of the same concentration, and the extract was obtained by filtration, and the two ethanol extracts were combined. Concentrate the extract under reduced pressure at 50°C to form an extract, recover ethanol during the concentration process, and finally vacuum-dry the extract below 60°C to obtain a powder that is ginsenoside extract.

[0041] The ginsenoside extract of the present embodiment is black brown powder.

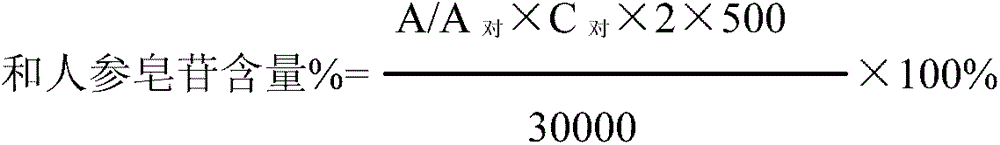

[00...

Embodiment 2

[0044] Weigh 100g of ginseng medicinal material, soak overnight, cut into thin slices, add 400mL of water, add 75mg of cellulase, 75mg of pectinase, react at 45°C for 1 hour, then add 200mL of 95% ethanol to the extract to form ethanol extraction solution, reflux at 55°C for 3 hours, and filter to obtain an extract; add 800 mL of ethanol solution of the same concentration to the residue, reflux at 55°C for 2 hours, filter to obtain an extract, and combine the two ethanol extracts. Concentrate the extract under reduced pressure at 50°C to form an extract, recover ethanol during the concentration process, and finally dry the extract under vacuum at a temperature below 60°C to obtain a powder that is the ginsenoside extract of this example. The yield of ginsenosides extracted by enzymatic method determined by colorimetry is 47.6% higher than that extracted by simple hot alcohol reflux method.

Embodiment 3

[0046] Weigh 100g of ginseng medicinal material, soak overnight, cut into thin slices, add 400mL of water, add 150mg of cellulase, react at 45°C for 1 hour, add 200mL of ethanol with a volume concentration of 95% to make an ethanol solution, reflux at 55°C for 3 hours, and filter to obtain Extract solution; add 800 mL of ethanol solution of the same concentration to the residue, reflux at 55°C for 2 hours, filter to obtain the extract solution, and combine the two ethanol extract solutions. The extract is concentrated under reduced pressure at 50°C to form an extract, ethanol is recovered during the concentration process, and finally the extract is further vacuum-dried below 60°C to obtain an extract that is ginsenoside extract. The yield of ginsenosides extracted by enzymatic method determined by colorimetry is 32.3% higher than that extracted by simple hot alcohol reflux method.

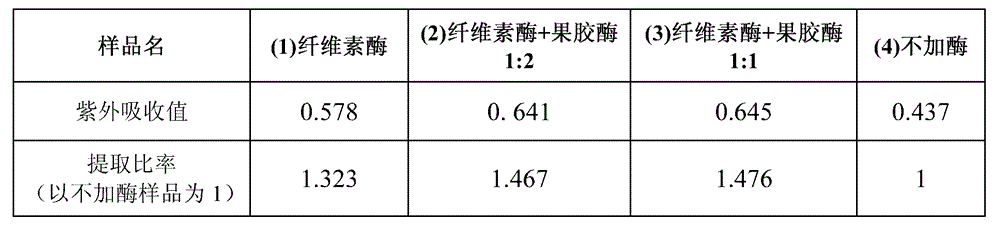

[0047] 1. Extraction method and grouping

[0048] Weigh four portions of 100g of ginseng medic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com