Combined extraction process of pea starch and protein

A pea starch and combined extraction technology, which is applied in the field of starch processing, can solve the problems of high production cost, low recovery rate, non-compliance, etc., and achieve the effects of low production cost, high production efficiency and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A joint extraction process of pea starch and protein, the process comprises the following steps:

[0029] Step 1. Soak, soak the peas after removing impurities until they fully absorb water and swell, and peel them for later use;

[0030] Step 2, grinding, grinding the peeled peas to obtain pea slurry, the mass ratio of peas and water in the grinding process is 1:8-9;

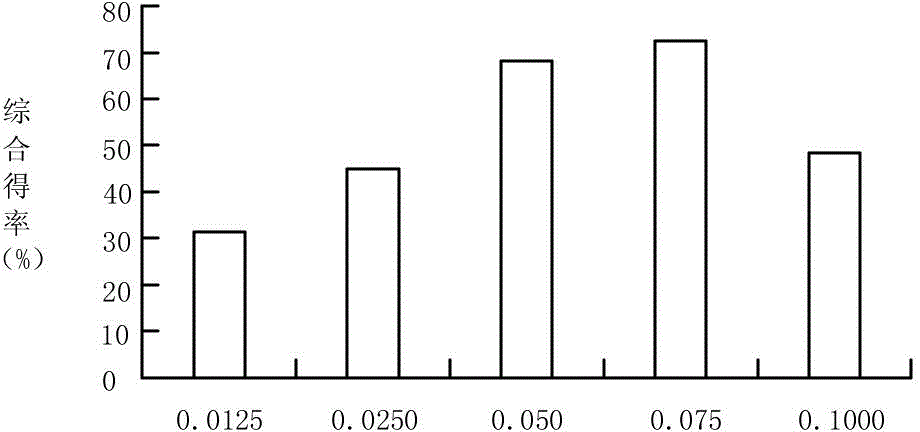

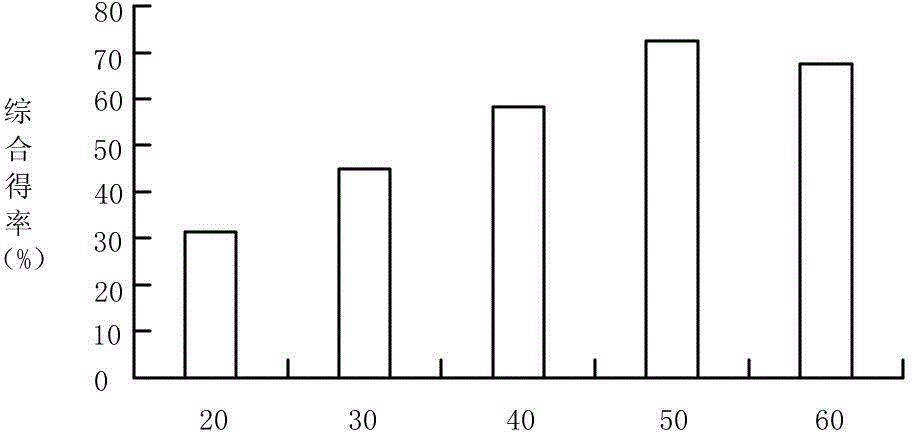

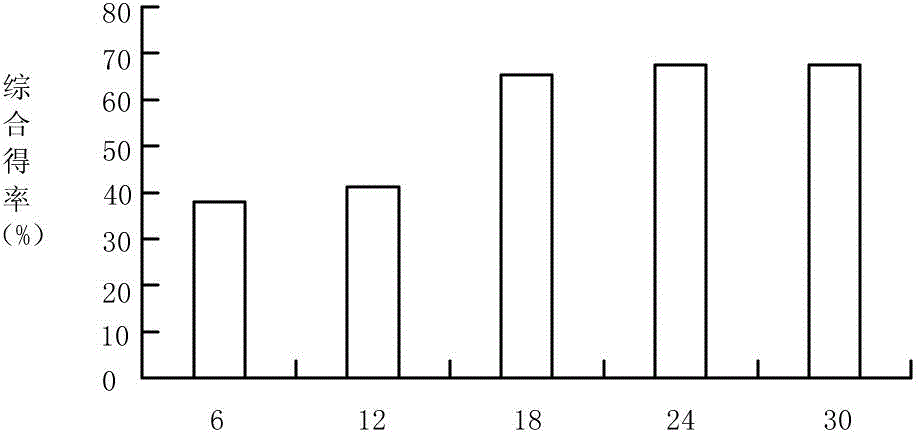

[0031] Step 3, leaching, the pea slurry after grinding is subjected to leaching reaction in a constant temperature heating agitator, and a NaOH solution with a concentration of 0.075mol / L is added to obtain a slurry with a material-to-liquid ratio of 1:18, and then, keep leaching The extraction temperature is 30°C, the extraction is stirred for 18 hours, and the extraction slurry is obtained; wherein, the ratio of solid to liquid is the ratio of the mass of the pea slurry to the volume of the NaOH solution;

[0032] Step 4, filtering, taking the extraction slurry, filtering it with a 100-120 mesh sieve ...

Embodiment 2

[0036] The difference between this example and Example 1 is that in step 3, the concentration of NaOH is 0.08mol / L, the solid-liquid ratio of the slurry is 1:24, the extraction temperature is 50°C, and the extraction temperature is 50°C. The stirring time was continued for 20 hours to obtain a leaching slurry.

[0037] Adopting the starch content determination and protein content determination methods commonly used in this field, combined with the comprehensive yield calculation method of pea starch and protein, the pea starch yield obtained is 75.0%, and the purity is 85.4% (dry basis); the pea protein yield is 58.9%, the purity is 78.4% (dry basis), and the comprehensive yield is 68.5%.

Embodiment 3

[0039] The difference between this example and Example 1 is that in step 3, the concentration of NaOH is 0.06mol / L, the solid-liquid ratio of the slurry is 1:18, the extraction temperature is 30°C, and the extraction temperature is 30°C. The stirring time was continued for 16 hours to obtain a leaching slurry.

[0040] Adopt the starch content determination and protein content determination method commonly used in this field, combine the comprehensive yield calculation method of pea starch and protein, the pea starch yield that obtains is 75.7%, and purity is 86.2% (dry basis); The pea protein yield is 59.6%, the purity is 78.9% (dry basis), and the comprehensive yield is 69.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com