High oil-absorbing resin and preparation method for same

A technology of super oil absorbent resin and fatty sodium, applied in the preparation of the resin, in the field of super oil absorbent resin, can solve the problems of limited application of olefin super oil absorbent resin, high price, few sources of high-carbon olefins, etc., so as to reduce synthesis cost and price Inexpensive, low-equipment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

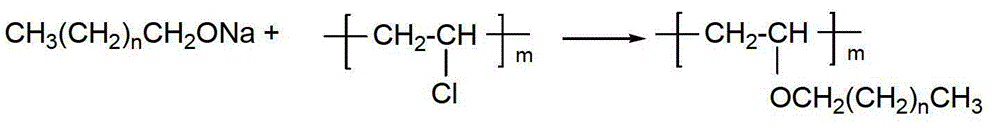

Method used

Image

Examples

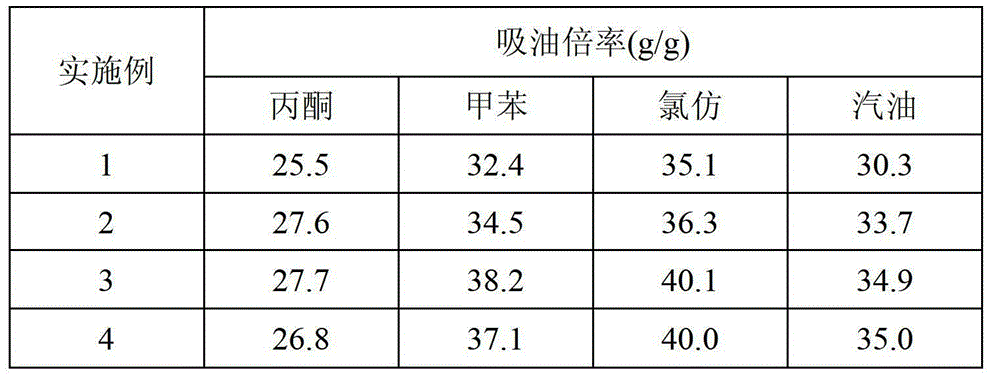

Embodiment 1

[0032] In the super oil-absorbing resin of this embodiment, n-hexanol and sodium methylate are mixed and reacted first to prepare sodium n-hexoxide, then sodium n-hexoxide is reacted with polyvinyl chloride to prepare a comb-shaped polymer, and then the comb-shaped polymer is mixed with butyl acrylate, dimethicone Vinyl benzene and benzoyl peroxide cross-linking reaction that is.

[0033] The preparation method of the super oil-absorbing resin of the present embodiment is characterized in that, comprises the following steps:

[0034] 1) Preparation of sodium n-hexylate:

[0035] Mix sodium methoxide and n-hexanol at a molar ratio of 1.1:1 and add molecular sieves, react in an oil bath at 110°C and a relative vacuum of -0.07MPa until no bubbles are formed in the liquid, and cool to room temperature to obtain the product;

[0036] 2) Preparation of comb polymer:

[0037] Polyvinyl chloride is dissolved in toluene solution to form a polyvinyl chloride toluene solution with a ma...

Embodiment 2

[0041] For the super oil-absorbing resin of this embodiment, n-octanol and sodium methoxide are first mixed and reacted to prepare sodium n-octoxide, then sodium n-octoxide and polyvinyl chloride are reacted to prepare a comb-shaped polymer, and then the comb-shaped polymer is mixed with butyl acrylate Ester, diisocyanate and lauroyl peroxide cross-linking reaction that is.

[0042] The preparation method of the super oil-absorbing resin of the present embodiment is characterized in that, comprises the following steps:

[0043] 1) Preparation of sodium n-octanate:

[0044] Mix sodium methoxide and n-octanol at a molar ratio of 1.05:1 and add molecular sieves, react in an oil bath at 120°C and a relative vacuum of -0.02MPa until no bubbles are formed in the liquid, and cool to room temperature to obtain the product;

[0045] 2) Preparation of comb polymer:

[0046] Polyvinyl chloride is dissolved in chlorobenzene solution to form a chlorobenzene solution of polyvinyl chloride...

Embodiment 3

[0050] For the super oil-absorbing resin of this embodiment, n-decyl alcohol and sodium ethylate are mixed and reacted to prepare sodium n-decyl alkoxide, then sodium n-decyl alkoxide and polyvinyl chloride are reacted to prepare a comb-shaped polymer, and then the comb-shaped polymer is mixed with butyl acrylate Esters, hydroxyethyl acrylate and methyl ethyl ketone peroxide cross-linking reaction that is.

[0051]The preparation method of the super oil-absorbing resin of the present embodiment is characterized in that, comprises the following steps:

[0052] 1) Preparation of sodium n-decyl alcohol:

[0053] Mix sodium ethoxide and n-decyl alcohol at a molar ratio of 1.15:1 and add molecular sieves, react in an oil bath at 110°C and a relative vacuum of 0.05MPa until no bubbles are formed in the liquid, and cool to room temperature to obtain the product;

[0054] 2) Preparation of comb polymer:

[0055] Dissolve polyvinyl chloride in the cyclohexanone solution to form a pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com