High-energy rubber product as well as preparation method and application thereof

A high-energy glue and product technology, applied in the field of internal filling and foaming, can solve the problems of lack of support, affecting product processing, low production efficiency, etc., to achieve the effect of enhancing strength and toughness, improving work efficiency, and reducing defective rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of high-energy adhesive products

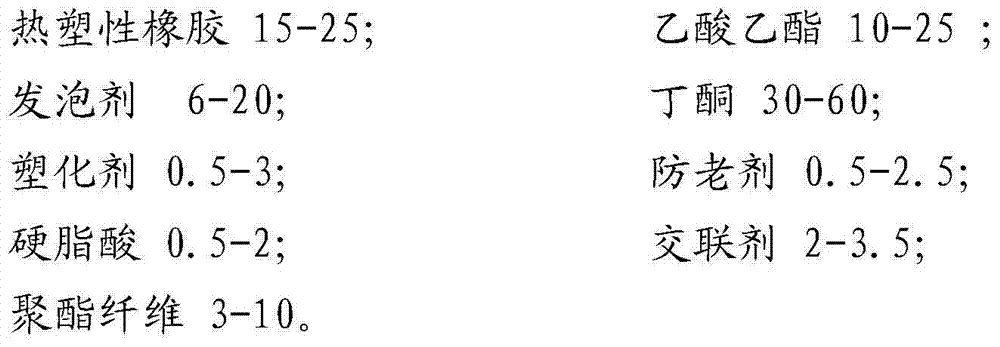

[0036] According to kilogram weight, the composition is:

[0037] Thermoplastic Rubber 15 Ethyl Acetate 25

[0038] Hydrofluorocarbon blowing agent 6 Butanone 60

[0039] Plasticizer (dibutyl phthalate) 0.5 Anti-aging agent (N-phenyl-α-aniline) 0.5

[0040] Stearic acid 0.5 Crosslinking agent (dicumyl peroxide) 2

[0041] Polyester fiber 3 (polyester fiber length should not be greater than 3mm)

[0042] Preparation method: Add thermoplastic rubber into a container filled with methyl ethyl ketone, fully stir and dissolve. 2. Add ethyl acetate and hydrogenated fluorocarbon foaming agent in sequence, and stir well to dissolve. 3. Add plasticizer, anti-aging agent, stearic acid and cross-linking agent under the condition of stirring. 4. After the solution is fully mixed, add polyester fiber and stir for 4-5 hours.

Embodiment 2

[0043] Embodiment 2: the preparation of high-energy glue product

[0044] According to kilogram weight, the composition is:

[0045] Thermoplastic Rubber 15 Ethyl Acetate 10

[0046] Hydrofluorocarbon blowing agent 6 Butanone 30

[0047] Plasticizer (dibutyl phthalate) 0.5 Anti-aging agent (N-phenyl-α-aniline) 0.5

[0048] Stearic acid 0.5 Crosslinking agent (dicumyl peroxide) 2

[0049] Polyester 3

[0050] Preparation method: Add thermoplastic rubber into a container filled with methyl ethyl ketone, fully stir and dissolve. 2. Add ethyl acetate and hydrogenated fluorocarbon foaming agent in sequence, and stir well to dissolve. 3. Add plasticizer, anti-aging agent, stearic acid and cross-linking agent under the condition of stirring. 4. After the solution is fully mixed, add polyester fiber and stir for 4-5 hours.

Embodiment 3

[0051] Embodiment 3: the preparation of high-energy glue products

[0052] According to kilogram weight, the composition is: same as above

[0053] Thermoplastic Rubber 20 Ethyl Acetate 15

[0054] Hydrofluorocarbon blowing agent 10 Butanone 40

[0055] Plasticizer (dibutyl phthalate) 1.5 Antiaging agent (N-phenyl-α-aniline) 1.5

[0056] Stearic acid 1.5 Crosslinking agent (dicumyl peroxide) 2.5

[0057] Polyester 6

[0058] Preparation method: Add thermoplastic rubber into a container filled with methyl ethyl ketone, fully stir and dissolve. 2. Add ethyl acetate and hydrogenated fluorocarbon foaming agent in sequence, and stir well to dissolve. 3. Add plasticizer, anti-aging agent, stearic acid and cross-linking agent under the condition of stirring. 4. After the solution is fully mixed, add polyester fiber and stir for 4-5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com