Phased array ultrasound detecting scanning path optimizing method based on defect detection rate

A defect detection rate and ultrasonic detection technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of difficult balance between detection ability and detection efficiency, expand the scanning range, etc., and achieve reduction The workload of data collection and data analysis, the effect of improving detection efficiency and simplifying process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

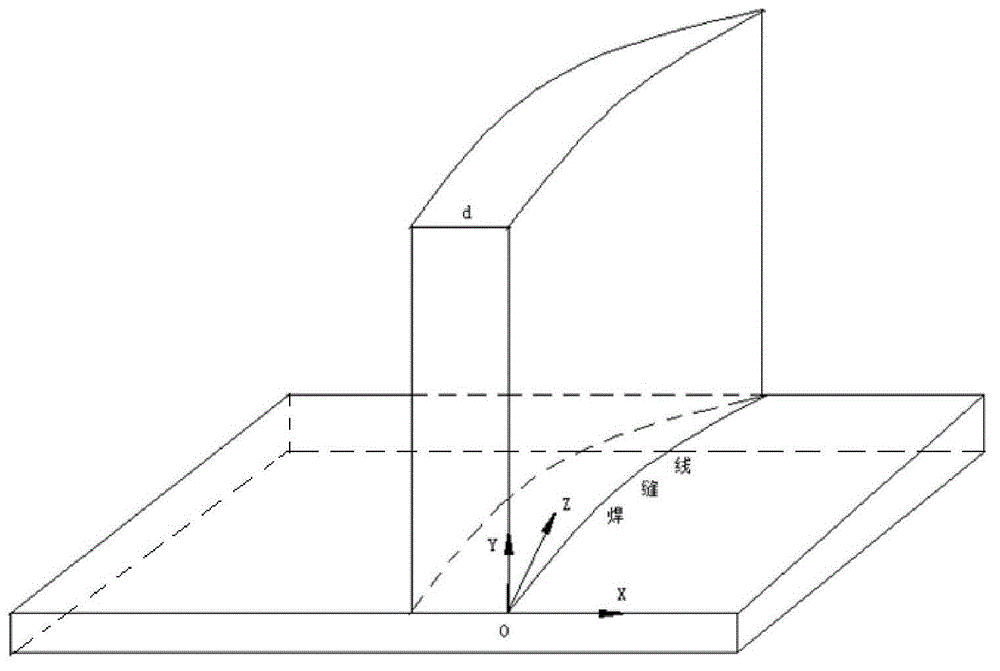

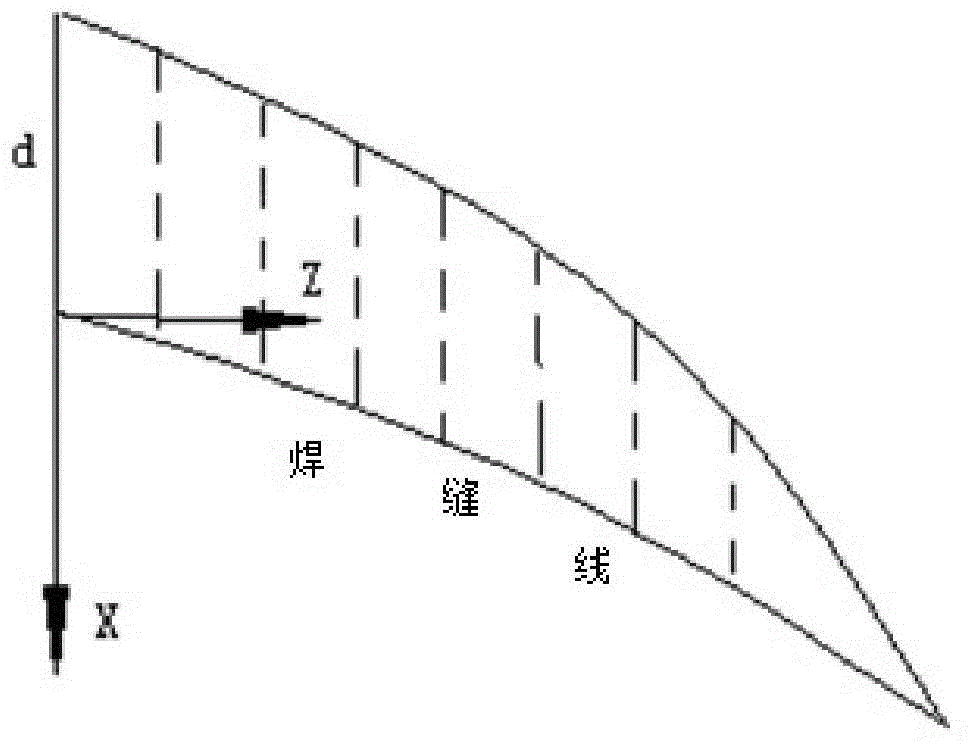

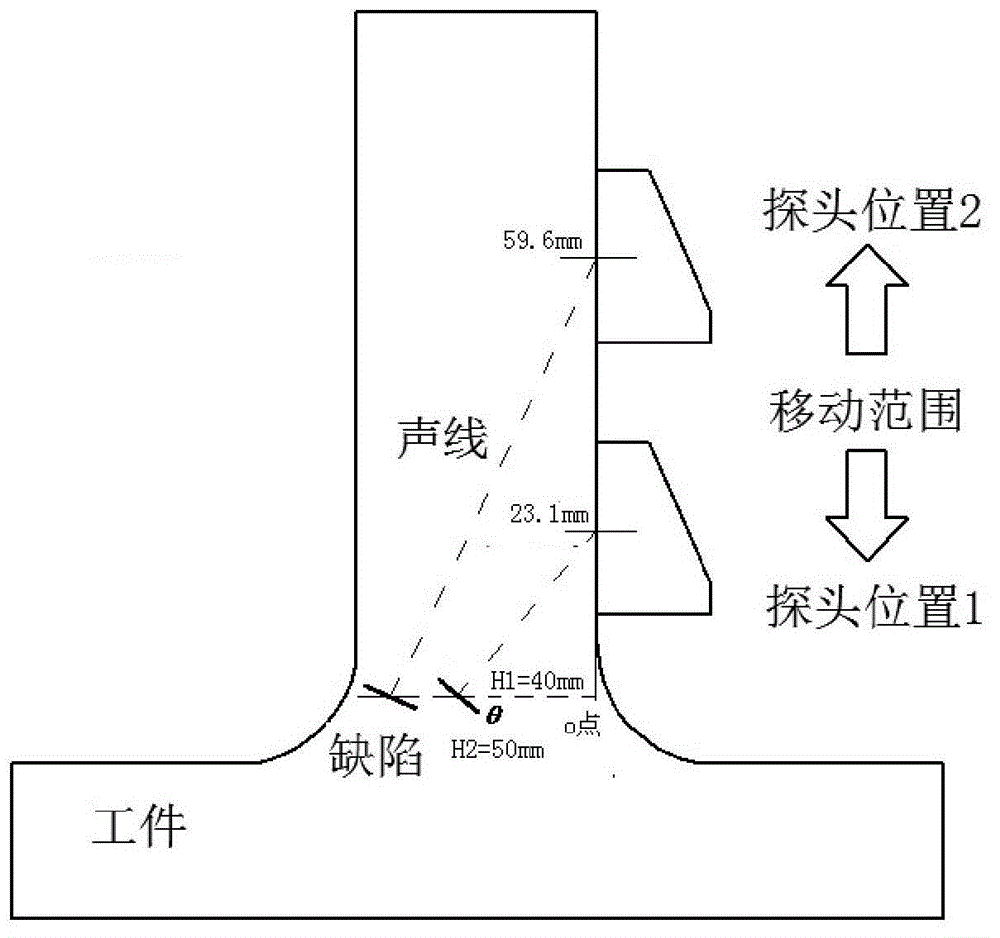

[0042] figure 1 Schematic diagram of the welded joints of the key components of the hydropower generating set. As shown in the figure, it is usually a three-dimensional variable section structure, including a vertical web d and two transverse flanges. Each section along the web d can be approximated as a T-shaped structure, but the webs between each section The thickness of d and the angle between the web d and the flange are different.

[0043] The implementation process of a method for optimizing the scanning path of phased array ultrasonic detection based on the defect detection rate of the method of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0044] S1 establishes a three-dimensional coordinate system according to the geometric shape of the joint, the distribution characteristics of the position prone to defects, and the scanning direction of the probe on the joint, and divides the joint into N detection areas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com